Sphingol pseudoalteromonas genetically engineered bacterium as well as construction method and application thereof

A technology of sphingomonas and genetically engineered bacteria, applied in chemical instruments and methods, bacteria, bacterial peptides, etc., can solve problems such as poor temperature and pH tolerance, and improve temperature tolerance and acid-base resistance Acceptability and economical improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

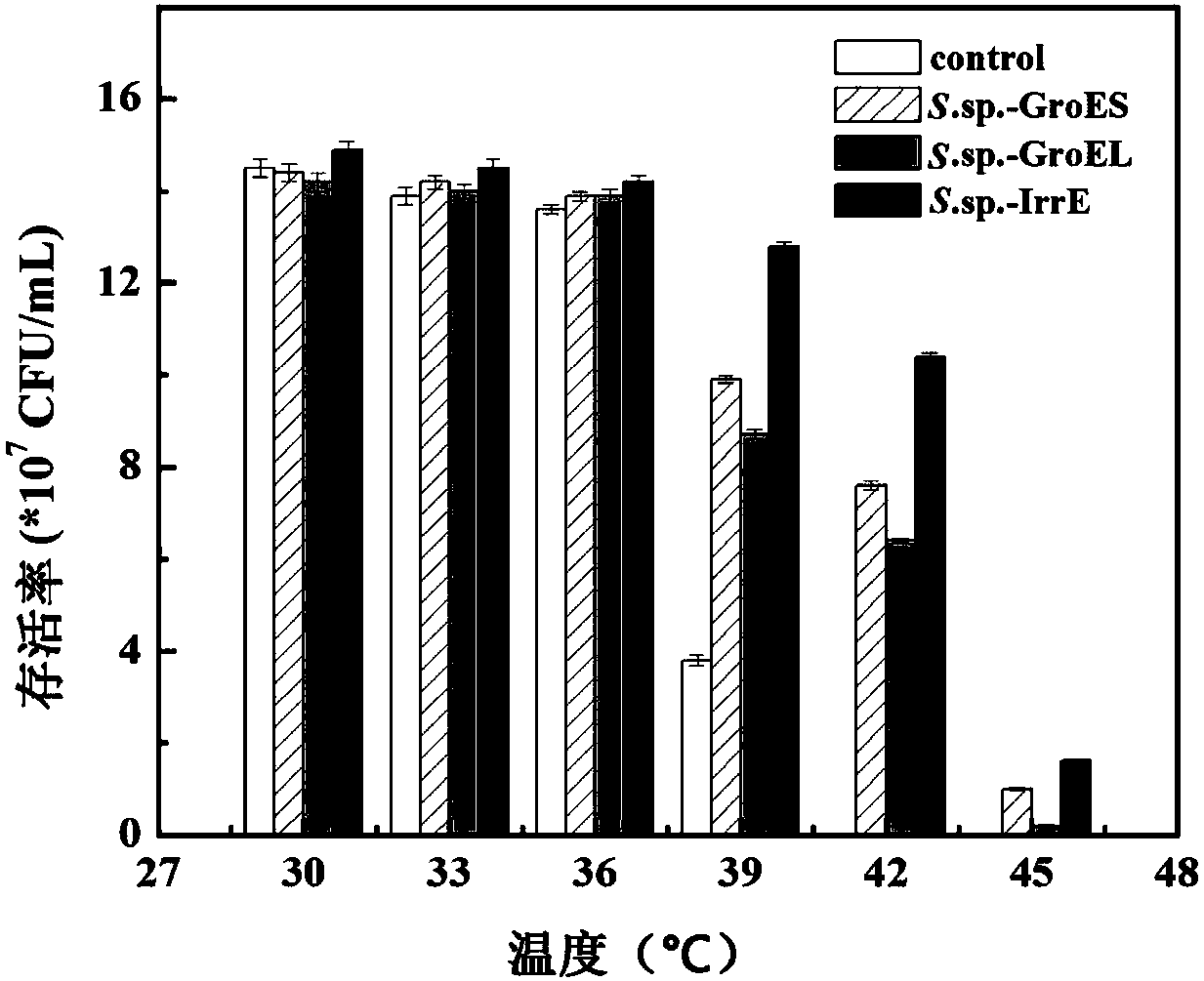

[0033] Example 1 Containing the Recombinant Sphingomonas Construction of Reversible Tengchong Thermotrophy GroES Gene

[0034] Step 1. Stress-resistant gene amplification

[0035] Using the Tengchong thermotrophic bacterium (CGMCC5161) genome as a template, use the software CE Design V1.0 primer design software to design synthetic primers (see Table 1 for primer sequences), and clone the stress-resistant GroES gene. The nucleotide sequence of the GroES gene is shown in SEQID NO : 1. PCR conditions for GroES gene: 1) Denaturation at 94°C for 5 min; 2) Cycle 30 times according to the following parameters: denaturation at 94°C for 1 min, annealing at 60°C for 60 s, extension at 72°C for 1 min; 3) final extension at 72°C for 10 min. After the completion of the PCR reaction, 2 μL of the product was taken, and then analyzed by electrophoresis in an agarose gel with a concentration of 1 g / 100 mL. After confirming the correct size of the fragment by imaging with a gel imaging system, ...

Embodiment 2

[0055] Embodiment 2 Construction of recombinant Sphingomonas containing anti-stress GroEL gene

[0056] The construction method is the same as in Example 1, except that the stress-resistant gene is the GroEL gene, derived from Thermus thermophilus (CGMCC15059), the nucleotide sequence is shown in SEQ ID NO: 2, the primer sequence list is shown in Table 1, and S .sp.GroEL

Embodiment 3

[0057] Embodiment 3 Construction of recombinant Sphingomonas containing stress-resistant IrrE gene

[0058] The construction method is the same as in Example 1, except that the stress-resistant gene is the IrrE gene, derived from Deinococcus radiodurans (CGMCC633), the nucleotide sequence is shown in SEQ ID NO: 5, the primer sequence list is shown in Table 1, and S. sp. IrrE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com