Permeable concrete and preparation technology and laying technology thereof

A technology of permeable concrete and preparation process, which is applied in the field of concrete, and can solve the problems of low structural strength and large application limitations of permeable concrete, and achieve the effects of improving water permeability, reducing clogging, and enhancing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

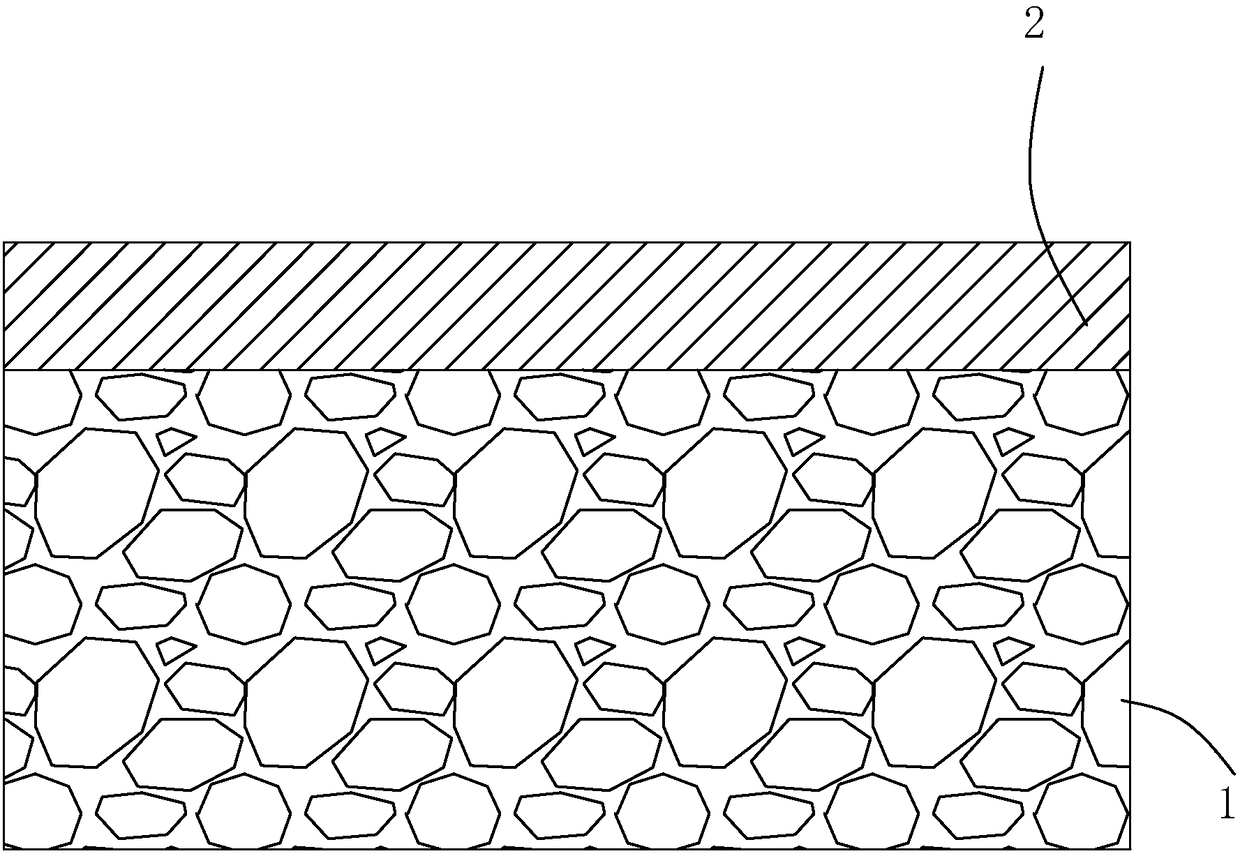

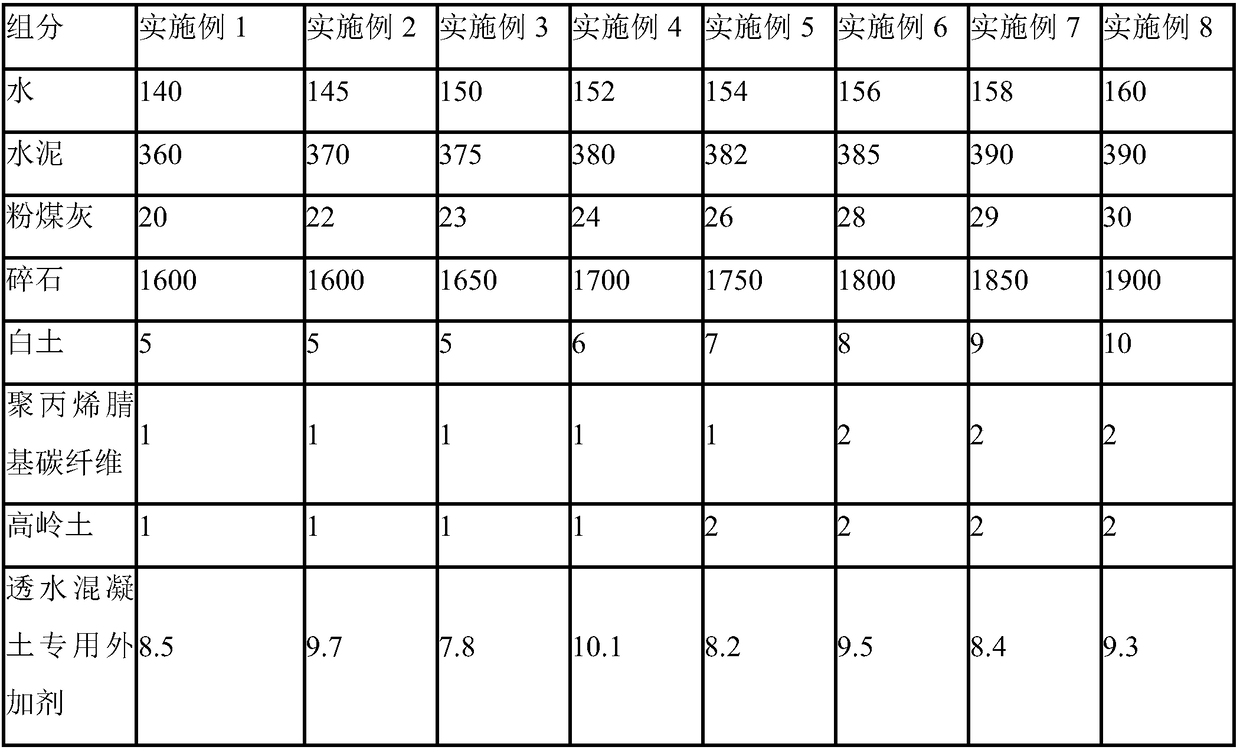

[0044] A permeable concrete such as figure 1 As shown, it includes a base layer 1 and a surface protection layer 2 disposed above the base layer 1 .

[0045] The base layer 1 includes water, cement, fly ash, gravel, white clay, polyacrylonitrile-based carbon fiber, kaolin, and special admixtures for permeable concrete.

[0046] The special admixture for permeable concrete includes the following components in parts by weight: calcium sulfoaluminate, cement, activated alumina, water reducing agent, hydrosol, slump retaining agent, water retaining agent, defoaming agent;

[0047] Binders include polyamide resin, absolute ethanol, silane coupling agent, phenolic accelerator and 2,4-di-tert-butylphenol;

[0048] As the water reducer, choose β-cyclodextrin polycarboxylate water reducer or shrinkage type polycarboxylate water reducer.

[0049](1) The synthetic method of β-cyclodextrin polycarboxylate superplasticizer is: TPEG (111.3g, 46.4mmol) and MA-β-CD (19.2g, 14.5mmol) are pla...

Embodiment 9

[0066] A preparation process of permeable concrete, comprising the following preparation steps:

[0067] S1: The preparation process of base layer 1:

[0068] Pour 10-20 parts of water into the mixer to wet the mixer;

[0069] Pour gravel and polyacrylonitrile-based carbon fiber into the mixer and mix evenly;

[0070] Add the remaining water and stir well;

[0071] Add cement, fly ash, clay, kaolin and special admixtures for permeable concrete to the mixer, and add dry ice to the mixer, and stir evenly;

[0072] S2: The preparation process of the surface protection layer 2:

[0073] The modified fly ash, fly ash ceramsite, bis-[γ-(triethoxysilicon) propyl]tetrasulfide, lotus leaf hydrophobic agent, ethylene-propylene rubber, glass powder, EVA and carbon nanotubes were sequentially Add to water and stir well.

Embodiment 10

[0075] A pavement process of permeable concrete, comprising the following pavement process:

[0076] Step 1: Transport the prepared base layer 1 to the paving site;

[0077] Step 2: Complete the vertical formwork production before paving; complete the watering and wetting of the construction surface, vertical formwork and other places in contact with the concrete pavement before paving; the paving coefficient is 1.1 to 1.25; use construction machinery to level, compact, and wipe flat;

[0078] Step 3: Evenly pave the surface protection layer 2 on the surface of the base layer 1 under the condition that the base layer 1 is semi-dry.

[0079] Test detection

[0080] 1. Test the mechanical properties of concrete according to GB / T 50081-2002 "Standard for Experimental Methods of Mechanical Properties of Ordinary Concrete";

[0081] 2. Test the mechanical properties of concrete according to GB / T 50080-2002 "Standard for Experimental Methods of Properties of Ordinary Concrete Mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com