Preparation method of niobium, tungsten and tantalum-doped cobalt trioxide

A technology of cobalt tetroxide and cobalt hydroxide, applied in the direction of cobalt oxide/cobalt hydroxide, can solve the problems of uneven precipitation, low production efficiency, easy hydrolysis, etc., and achieve the effect of promoting rapid growth and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

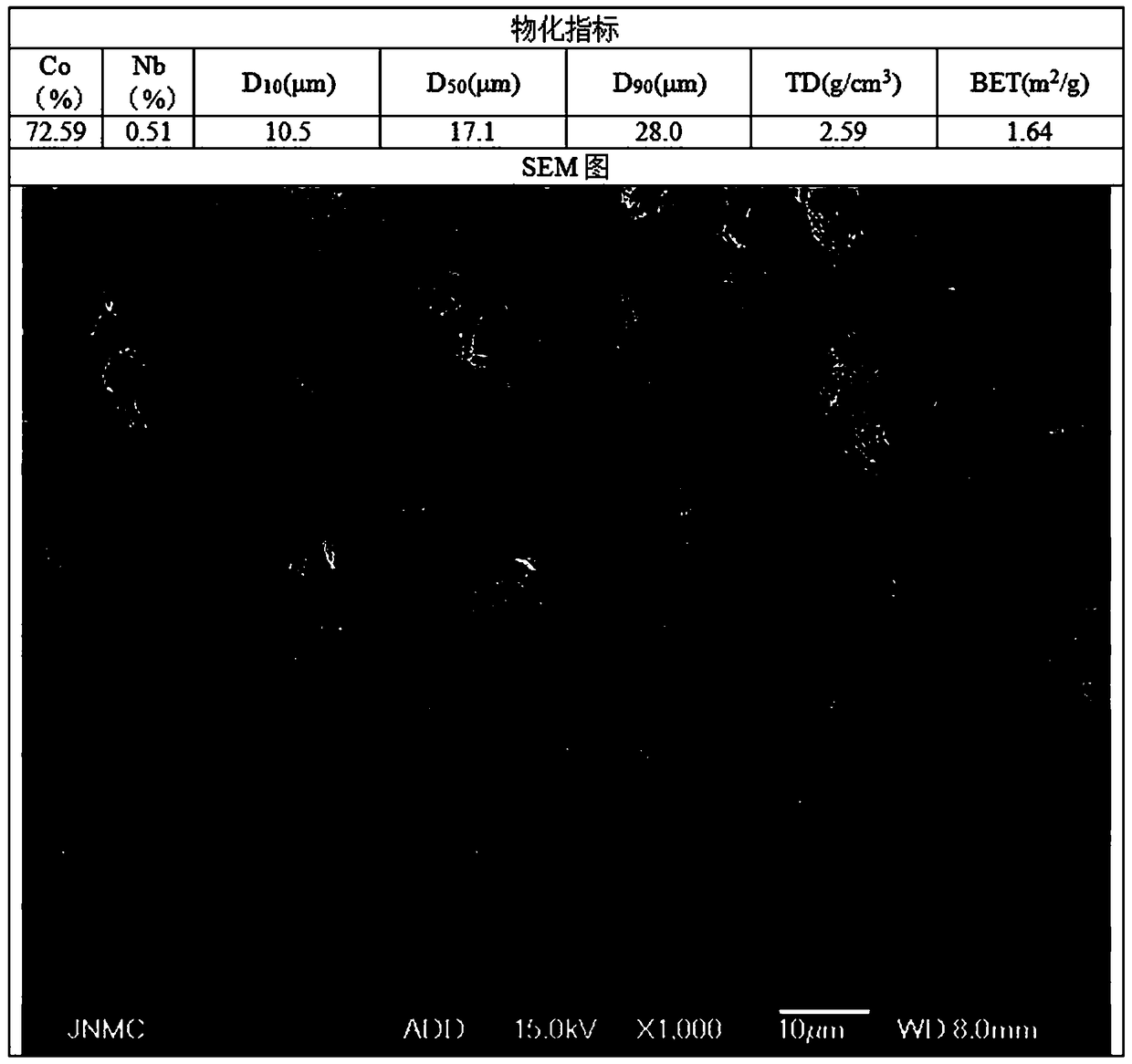

Embodiment 1

[0032] Prepare a cobalt chloride solution with a concentration of 1mol / L as solution A; prepare a sodium hydroxide solution with a concentration of 2mol / L as solution B; prepare an ammonia solution with a concentration of 5mol / L, and add 5mL volume fraction per liter of ammonia solution The 30% hydrazine hydrate solution is the C solution; the hydrogen peroxide solution with a concentration of 5mol / L is prepared as the D solution; the niobium pentachloride absolute ethanol solution with a concentration of 4g / L is prepared as the E solution.

[0033] At the beginning of the synthesis reaction, the A solution, the B solution and the C solution flow into the reactor simultaneously, and at the same time, the E solution feeding pipe is divided into 6-9 small pipes, and the liquid outlet of each fine feeding pipe is fixed to the reactor for stirring Add E solution to the middle or tail of the paddle, and react under the stirring state of 500r / min. Adjustment, the flow rate of soluti...

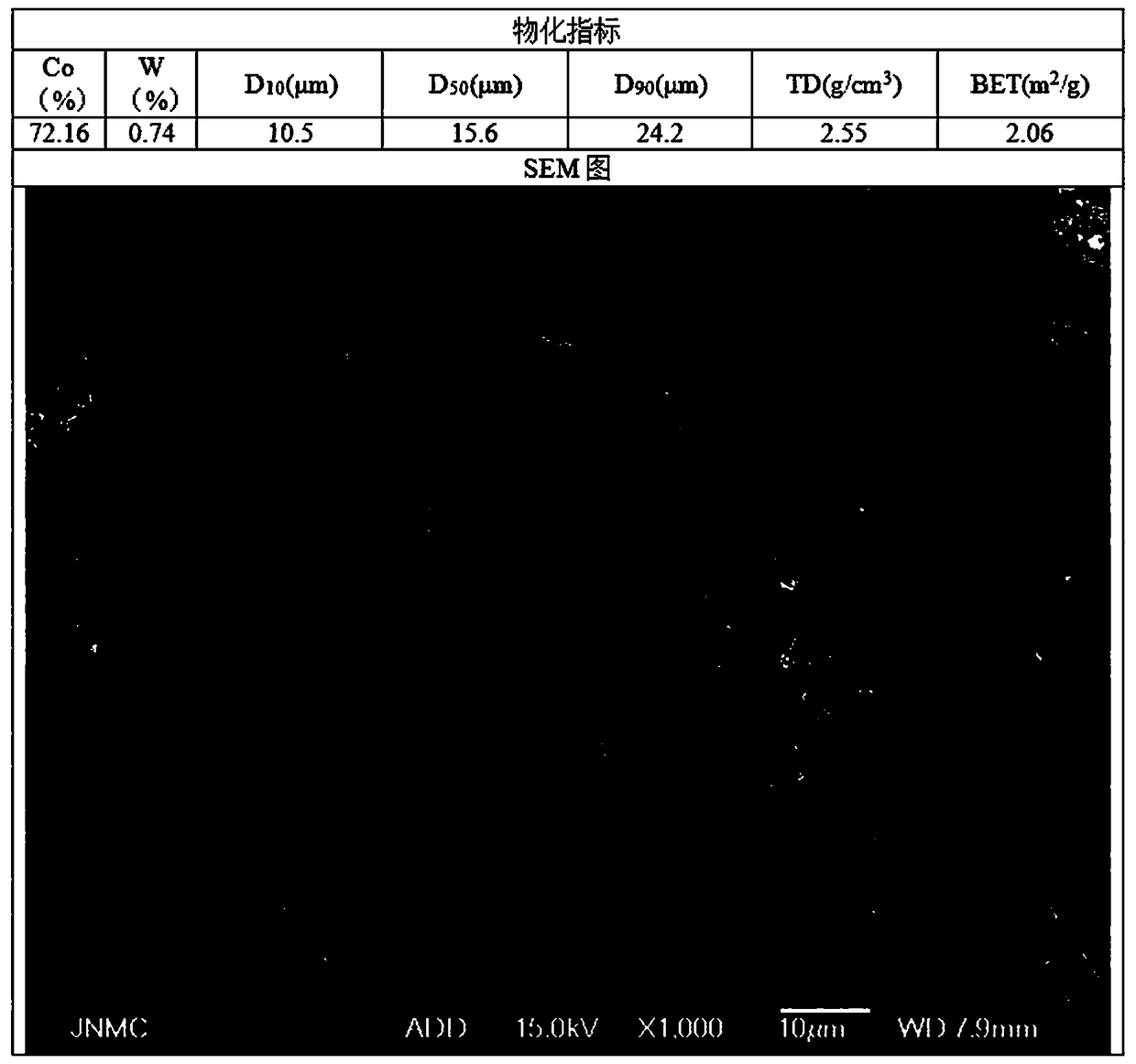

Embodiment 2

[0038] Prepare a cobalt sulfate solution with a concentration of 1.5mol / L as solution A; prepare a sodium hydroxide solution with a concentration of 4mol / L as solution B; prepare an ammonia solution with a concentration of 8mol / L, and add 15mL volume fraction per liter of ammonia solution A 30% hydrazine hydrate solution is solution C; a hydrogen peroxide solution with a concentration of 6mol / L is prepared as solution D; a tungsten hexachloride absolute ethanol solution with a concentration of 6g / L is prepared as solution E.

[0039]At the beginning of the synthesis reaction, the A solution, the B solution and the C solution flow into the reactor simultaneously, and at the same time, the E solution feeding pipe is divided into 6-9 small pipes, and the liquid outlet of each fine feeding pipe is fixed to the reactor for stirring Add E solution to the middle or tail of the paddle, and react under the stirring state of 400r / min. The pH value of the reaction was adjusted, the flow ...

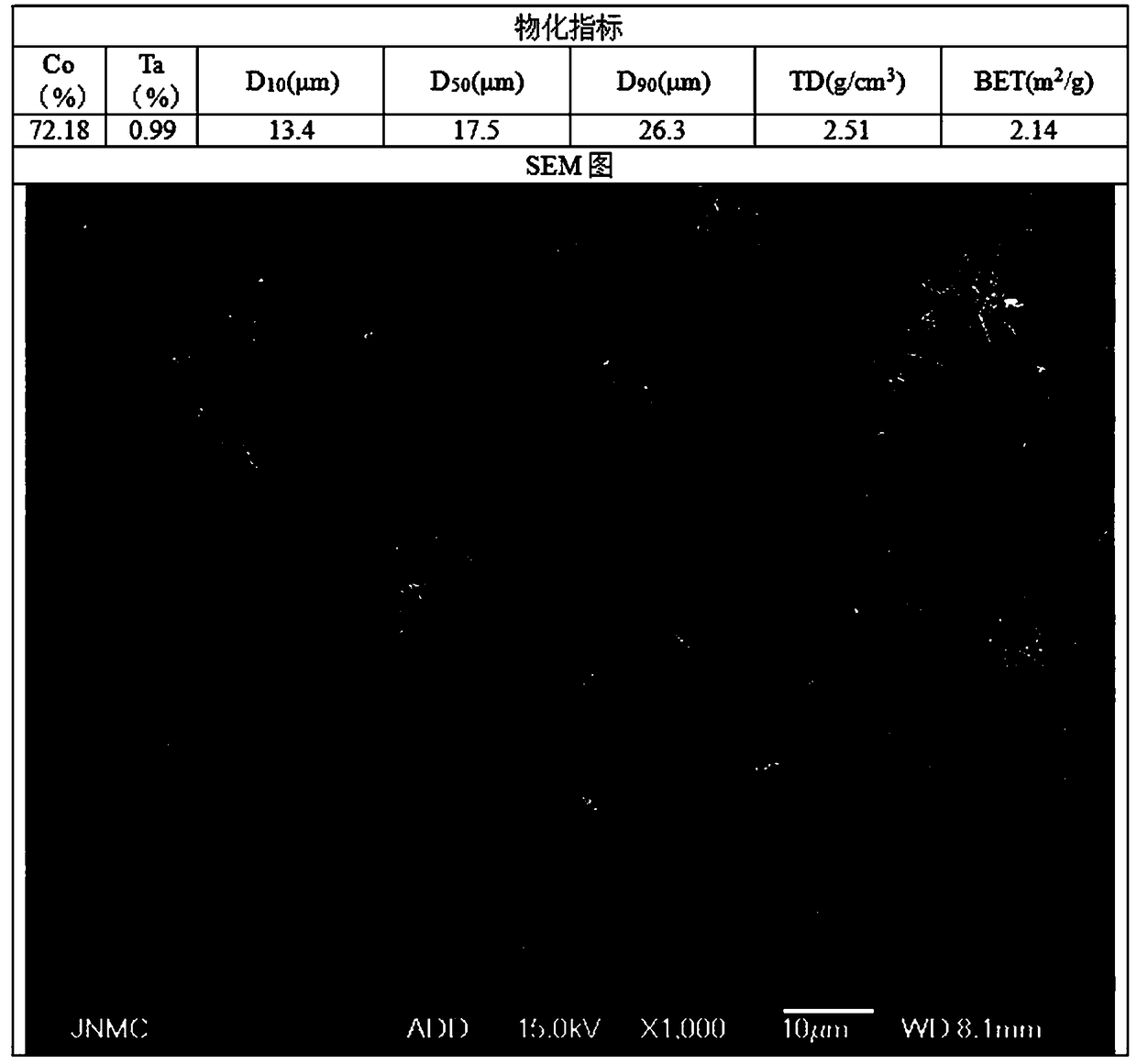

Embodiment 3

[0044] Prepare the cobalt nitrate solution with a concentration of 2mol / L as solution A; prepare the sodium hydroxide solution with a concentration of 6mol / L as solution B; The 30% hydrazine hydrate solution is solution C; the hydrogen peroxide solution with a concentration of 8 mol / L is prepared as solution D; the tantalum pentachloride absolute ethanol solution with a concentration of 8 g / L is prepared as solution E.

[0045] At the beginning of the synthesis reaction, the A solution, the B solution and the C solution flow into the reactor simultaneously, and at the same time, the E solution feeding pipe is divided into 6-9 small pipes, and the liquid outlet of each fine feeding pipe is fixed to the reactor for stirring Add E solution to the middle or tail of the paddle, and react under the stirring state of 300r / min. The pH value of the reaction was adjusted, the flow rate of solution C was 60 L / h, the flow rate of solution E was 30 L / h, and the reaction time was 20 h to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com