Stamping device with polishing function

A stamping device and functional technology, applied in the field of stamping devices with grinding function, can solve problems such as low efficiency and cumbersome procedures, and achieve the effects of improving efficiency, simplifying procedures and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

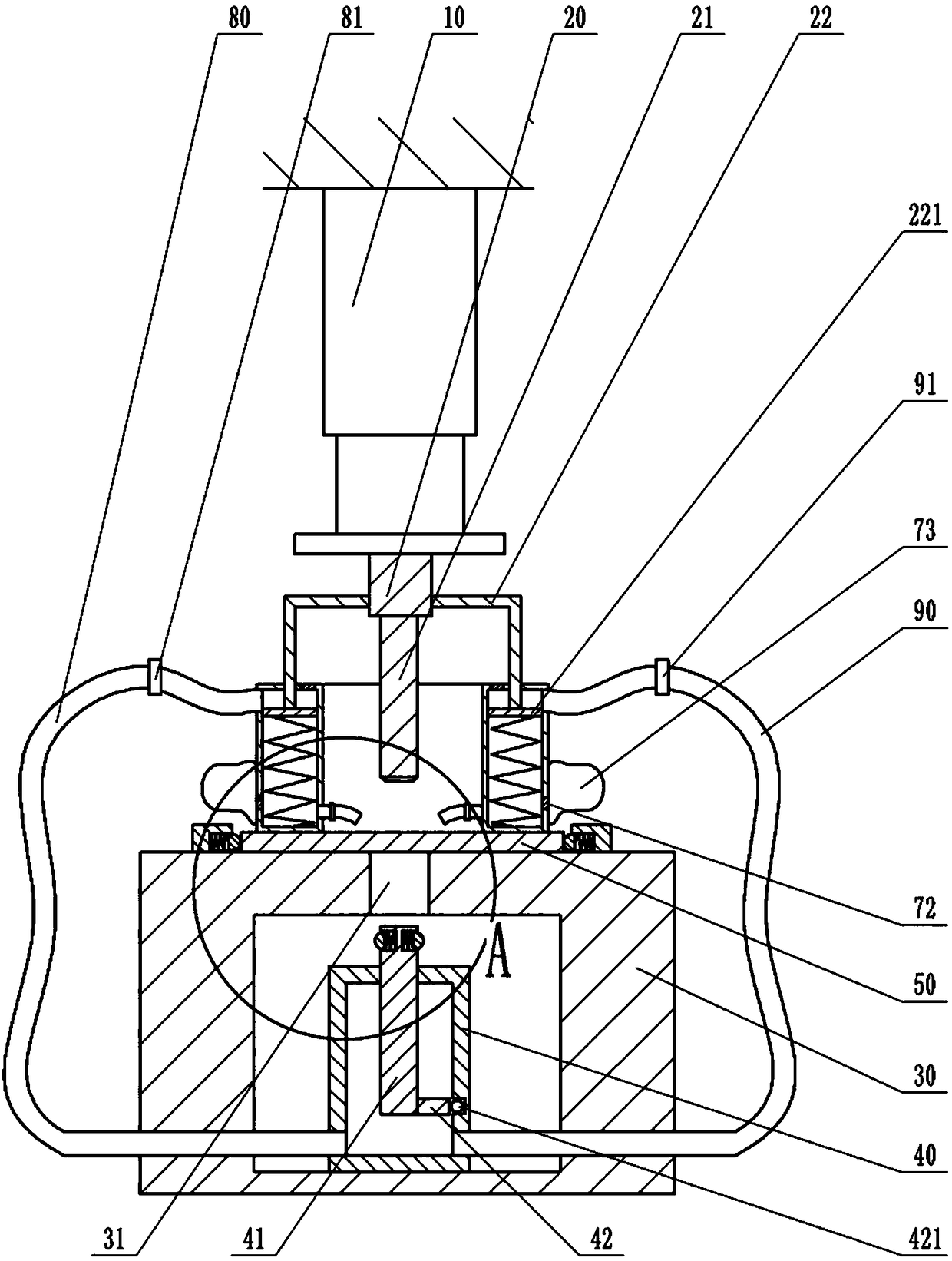

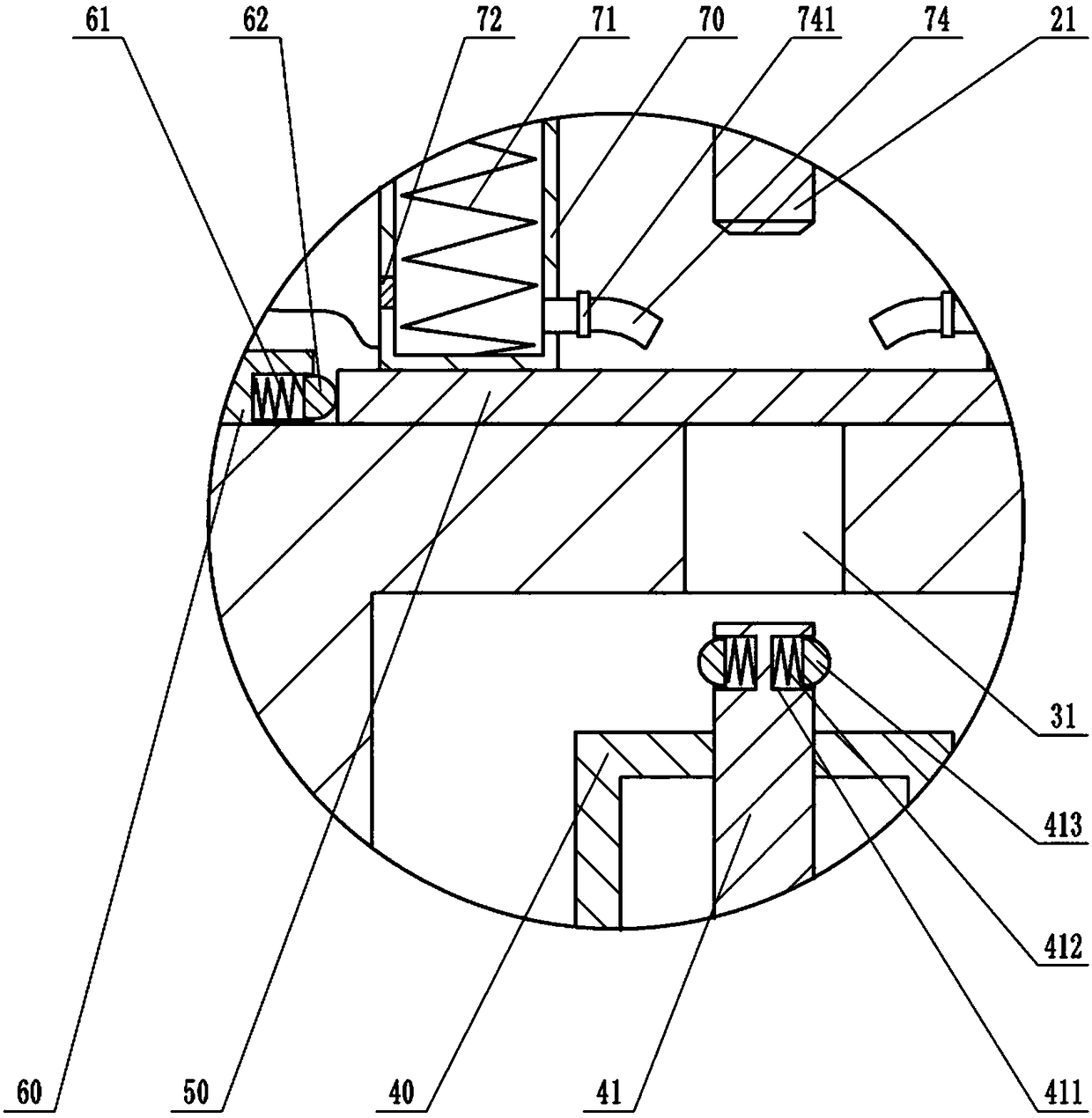

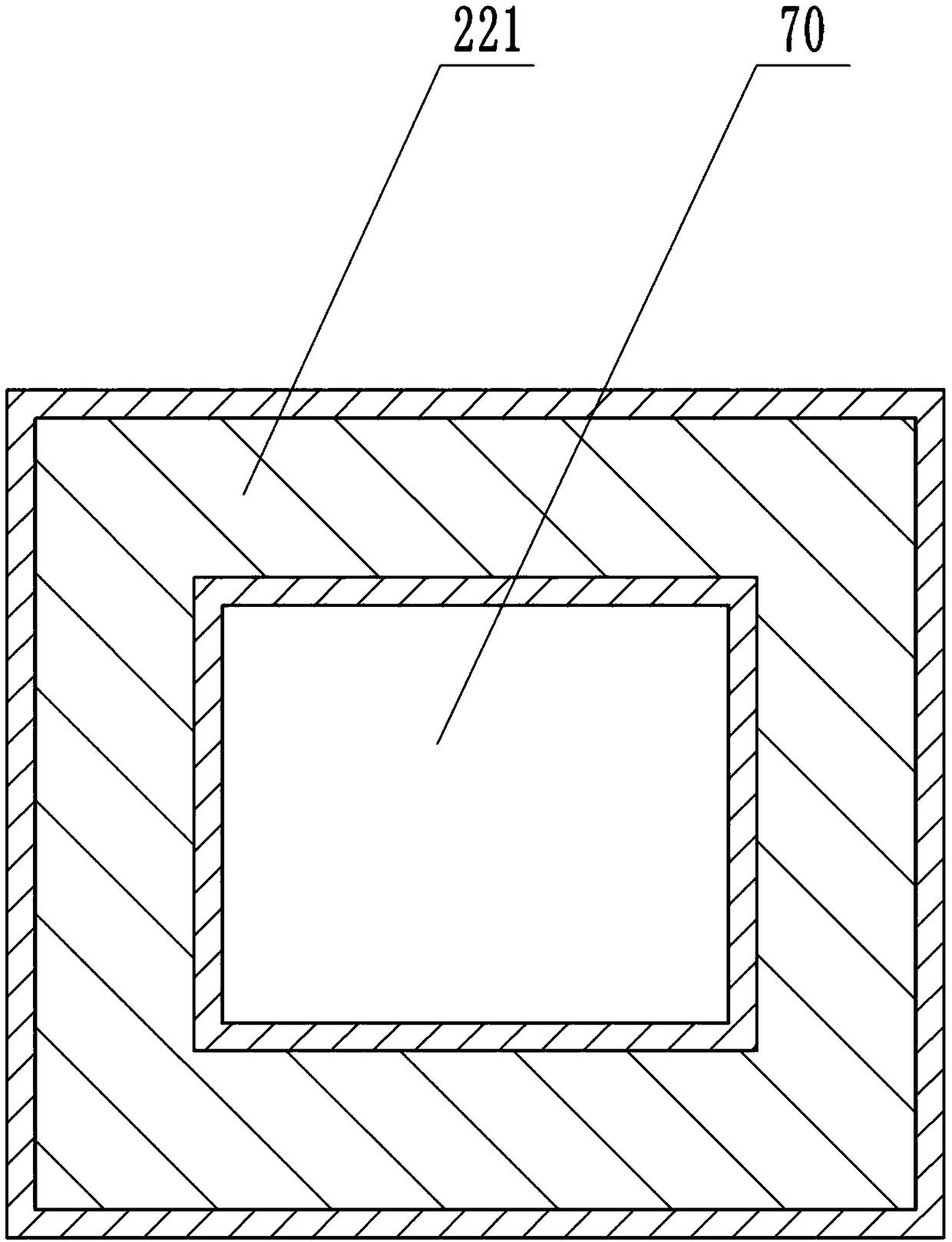

[0021] Instructions attached Figures 1 to 3 The reference signs in include: hydraulic cylinder 10, mounting seat 20, punch 21, push rod 22, piston 221, workbench 30, through hole 31, fixed cylinder 40, push column 41, concave cavity 411, first spring 412 , grinding protrusion 413, clamp rod 42, ball 421, workpiece 50, limit post 60, third spring 61, limit block 62, ring pressure block 70, second spring 71, one-way exhaust valve 72, filter bag 73, suction pipe 74, one-way air intake valve 741, air outlet pipe 80, second one-way valve 81, air intake pipe 90, first one-way valve 91.

[0022] Such as Figure 1-Figure 3 As shown, the stamping device with grinding function includes a workbench 30, an annular pressure block 70, a power mechanism and a mount 20 above the workbench 30. The lower surface of the mount 20 is welded with a punch 21, and the side of the mount 20 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com