Preparation method and application of core-shell magnetic gamma-cyclodextrin polymer composite material

A cyclodextrin polymer, composite material technology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of long operation process, easy blockage of extraction columns, etc., To achieve the effect of simple design, improvement of uneven coating and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

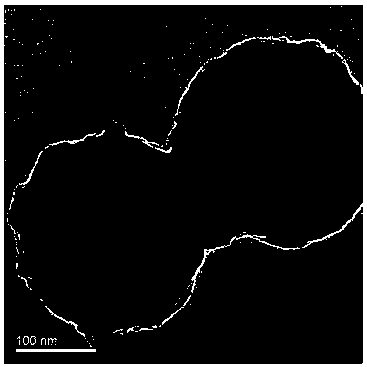

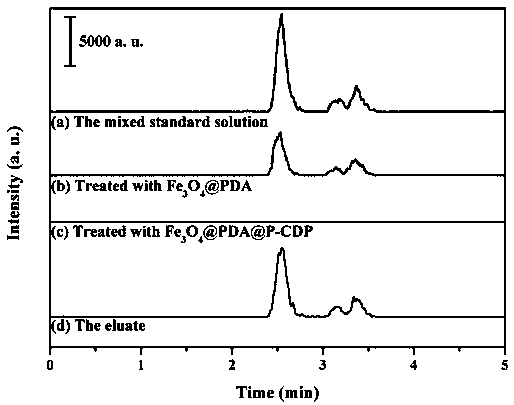

[0033] A preparation method of a core-shell magnetic gamma-cyclodextrin polymer composite material, specifically comprising the following steps:

[0034] (1) Fe 3 o 4 Preparation of magnetic balls

[0035] (a) Weigh 6.8 g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 2.0 g trisodium citrate (Na 3 Cit·2H 2 O) be dissolved in 200 mL ethylene glycol to obtain an orange clear solution;

[0036] (b) Add 12.0 g of sodium acetate (NaAc) to the solution obtained in step (a), continue magnetic stirring until dissolved, transfer the resulting solution to an 80 mL reactor, heat up to 200 °C and continue the reaction for 12 h;

[0037] (c) Wash the product obtained in step (b) alternately with ultrapure water and absolute ethanol three times each, perform magnetic separation with a magnet, and then dry to obtain Fe 3 o 4 Magnetic ball, spare;

[0038] (2) Fe 3 o 4 Preparation of @PDA core-shell materials

[0039] (1) Weigh 0.121 g of tris (Tris) and dissolve it in 100 mL of...

Embodiment 2

[0047] A preparation method of a core-shell magnetic gamma-cyclodextrin polymer composite material, specifically comprising the following steps:

[0048] (1) Fe 3 o 4 Preparation of magnetic balls

[0049] (a) Weigh 4 g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 2 g trisodium citrate (Na 3 Cit·2H 2 O) be dissolved in 150 mL ethylene glycol to obtain an orange clear solution;

[0050] (b) Add 10 g of sodium acetate (NaAc) to the solution obtained in step (a), continue magnetic stirring until dissolved, transfer the resulting solution to a reaction kettle, and heat up to 200 °C for 12 h;

[0051] (c) Wash the product obtained in step (b) alternately with ultrapure water and absolute ethanol three times each, perform magnetic separation with a magnet, and then dry to obtain Fe 3 o 4 Magnetic ball, spare;

[0052] (2) Fe 3 o 4 Preparation of @PDA core-shell materials

[0053] (1) Dissolve 0.1 g of tris (Tris) in 80 mL of secondary water to prepare a 10 mM buffer ...

Embodiment 3

[0061] A preparation method of a core-shell magnetic gamma-cyclodextrin polymer composite material, specifically comprising the following steps:

[0062] (1) Fe 3 o 4 Preparation of magnetic balls

[0063] (a) Weigh 8 g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 3 g trisodium citrate (Na 3 Cit·2H 2 O) be dissolved in 300 mL ethylene glycol to obtain an orange clear solution;

[0064] (b) Add 15 g of sodium acetate (NaAc) to the solution obtained in step (a), continue magnetic stirring until dissolved, transfer the resulting solution to a reaction kettle, heat up to 200 °C and continue the reaction for 12 h;

[0065] (c) Wash the product obtained in step (b) alternately with ultrapure water and absolute ethanol three times each, perform magnetic separation with a magnet, and then dry to obtain Fe 3 o 4 Magnetic ball, spare;

[0066] (2) Fe 3 o 4 Preparation of @PDA core-shell materials

[0067] (1) Dissolve 0.2 g of tris (Tris) in 150 mL of secondary water to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com