A high-precision adjustable servo motor control method

A technology of servo motor and control method, applied in the direction of motor control, control system, electrical components, etc., can solve the problem that the control accuracy of the servo motor cannot be further improved, and achieve the effect of eliminating the difference in motor output response and improving the control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the explanatory text.

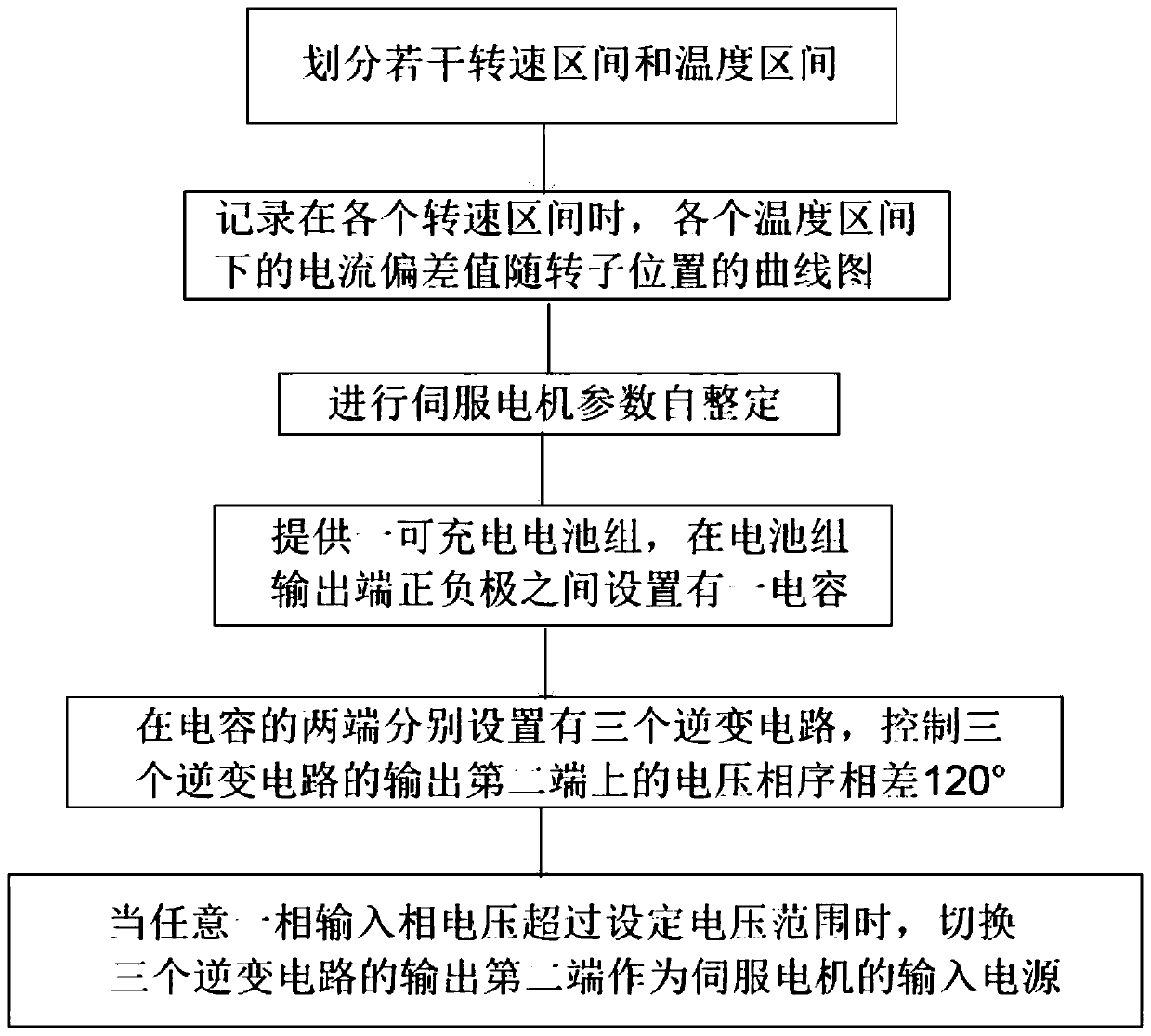

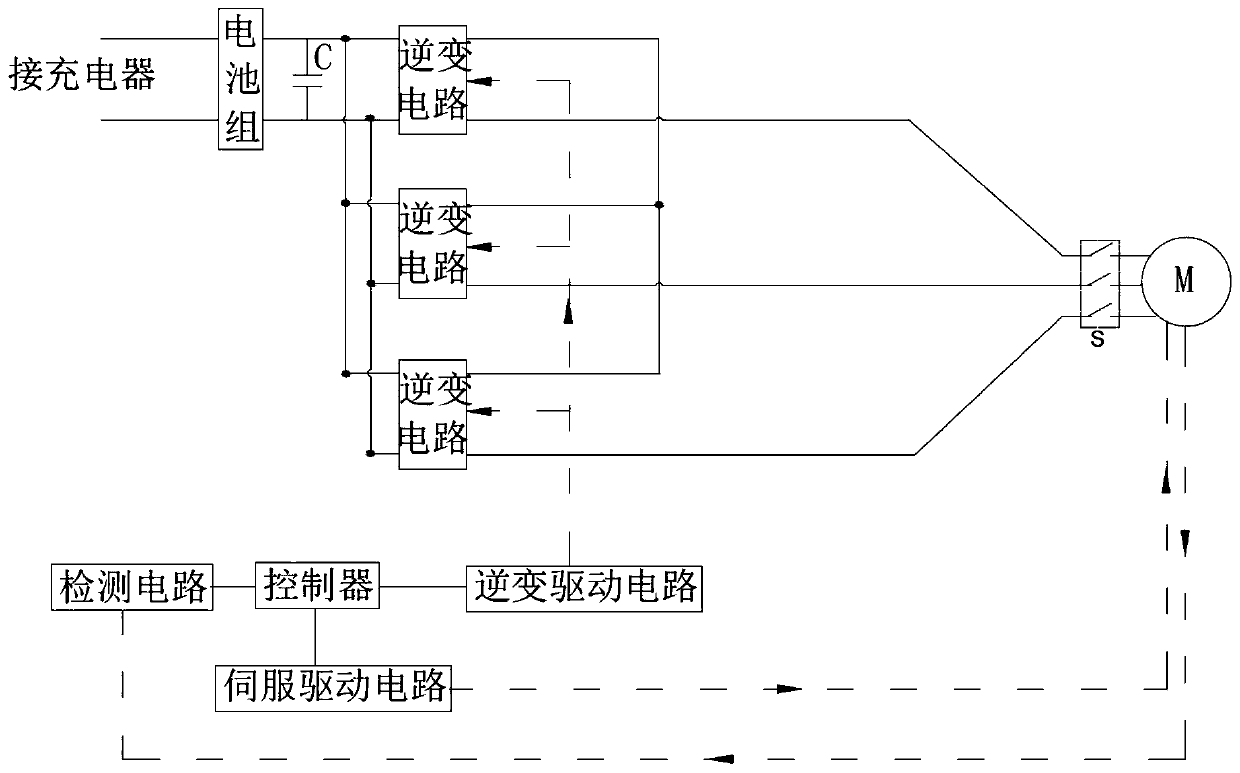

[0026] Such as Figure 1-2 As shown, the present invention provides a control method of a high-precision adjustable servo motor, comprising the following steps:

[0027] Step 1. Divide several rotational speed intervals at equal intervals according to the rotational speed range of the servo motor, and divide several temperature intervals at equal intervals according to the operating temperature range of the servo motor; The more accurate the position change curve is, the more accurate the self-tuning result of the servo motor parameters is, which in turn can improve the control accuracy of the servo motor. Specifically, the speed range and temperature range can be divided according to the servo motor parameters.

[0028] Step 2. Gradually increase the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com