Dry glove box aerosol monitoring system and dry glove box aerosol monitoring method

A monitoring system and aerosol technology, applied in the field of high-temperature molten salt metallurgy, can solve the problems of inability to online synchronous continuous measurement, insufficient air tightness, and atmosphere damage in dry glove boxes, and achieve easy decontamination, fast and convenient installation, and improved performance. The effect of maintenance life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

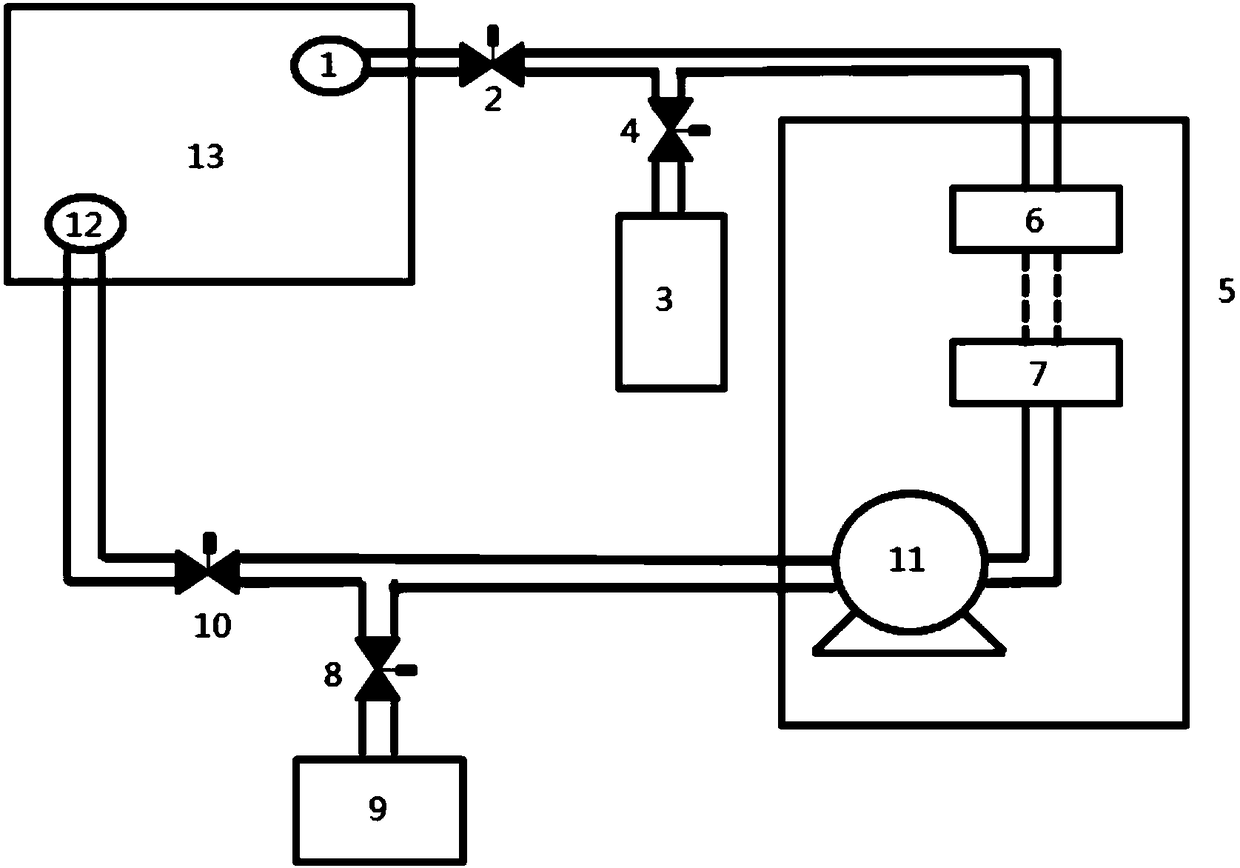

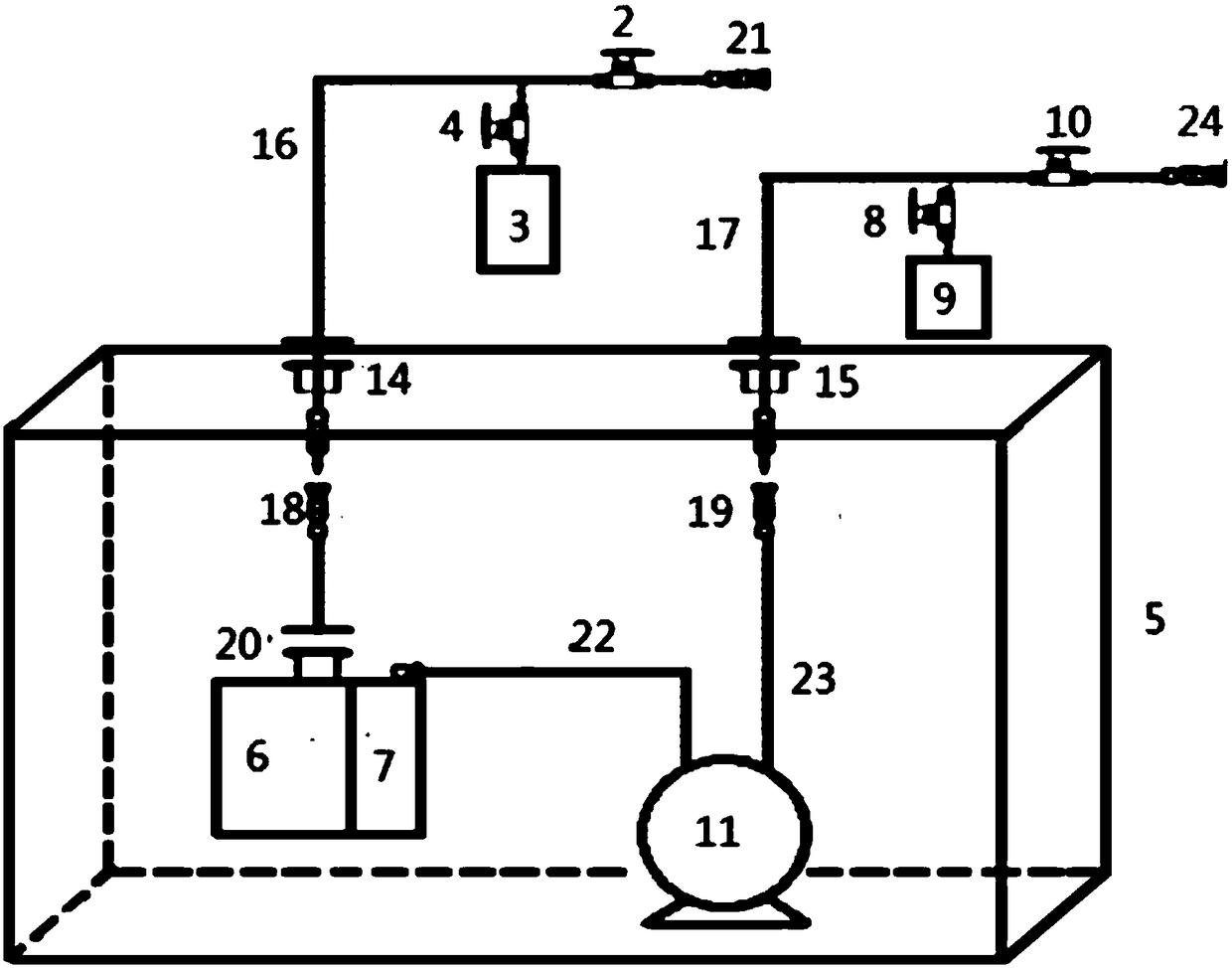

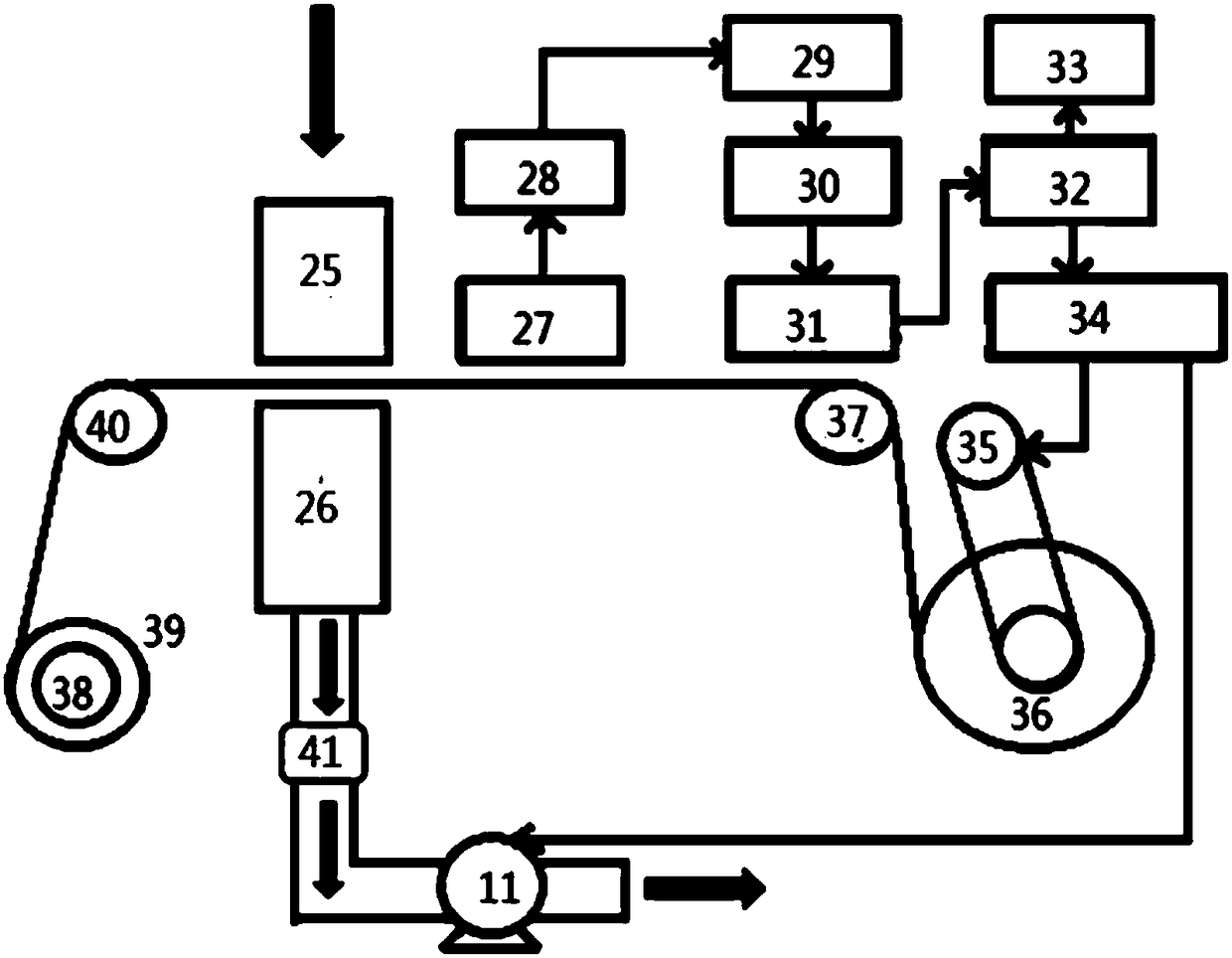

Method used

Image

Examples

experiment example 1

[0083] When handling plutonium dioxide subpackages, the aerosol concentration in the dry glove box is about 10 0.5 hours after the start of weighing. 4 Bq / m 3 , the aerosol concentration in the room is about 0.01Bq / m 3 , the water and oxygen content in the dry glove box are less than 1ppm.

experiment example 2

[0085] Using the same conditions as in Example 1, the aerosol concentration in the dry glove box was about 10 in 1 hour after weighing. 3 Bq / m 3 , the aerosol concentration in the room is about 0Bq / m 3 , water and oxygen content are less than 1ppm.

experiment example 3

[0087] Utilize the same condition of embodiment 1, the aerosol concentration in the dry method glove box is about 10 in 1.5 hours after starting to weigh. 2 Bq / m 3 , the aerosol concentration in the room is about 0Bq / m 3 , water and oxygen content are less than 1ppm.

[0088] From the results of the above examples, it can be concluded that this set of monitoring system and method can effectively realize the function of continuous aerosol monitoring without destroying the atmosphere in the dry glove box, and has good air tightness and accurate measurement data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com