Multi-gear gearbox for motor vehicle

A multi-gear and gearbox technology, which is applied in the direction of vehicle gearboxes, transmission components, transmission devices, etc., can solve the problems of shortening the service life of batteries, increasing the load of DC motors, and reducing the power of electric vehicles, etc., to reduce the volume , prolong service life and facilitate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

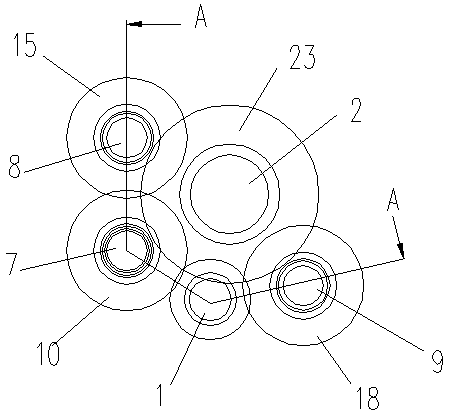

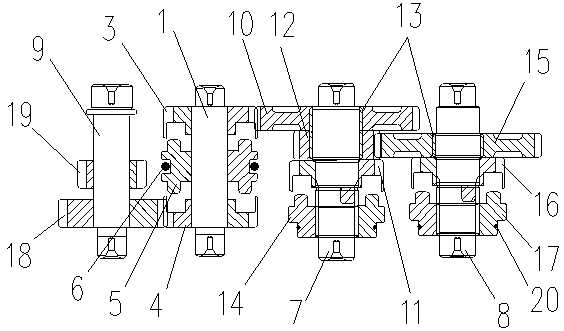

[0025] Example: see Figure 1 to Figure 5 , a multi-gear gearbox for an electric vehicle, comprising a box body, a power input shaft 1 and a power output shaft 2 . A power input gear I3 and a power input gear II4 are arranged on the power input shaft 1, and both the power input gear I3 and the power input gear II4 can be rotatably set on the power input shaft 1; during processing, the power input gear Ⅰ3 and power input gear Ⅱ4 are connected with the power input shaft 1 through ball bearings; thus, free forward and reverse rotation can be performed. A sliding member 5 is arranged between the power input gear I3 and the power input gear II4. In practice, a feather key is arranged on the power input shaft 1 between the power input gear I3 and the power input gear II4 along its axial direction. The inner side of the sliding part 5 is provided with a keyway, and the sliding part 5 is slidably connected with the power input shaft 1 through the cooperation of the keyway and the fea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com