System and method for in-situ cracking of oil shale

An oil shale, in-situ technology, applied in the field of in-situ cracking and exploitation of oil shale, can solve the problems of long heating cycle and low effective utilization rate, reduce the multi-level conversion of energy, shorten the in-situ cracking cycle, and improve the original The effect of in-situ cracking quality and recovery factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the examples and specific implementation manners. However, it should not be construed that the scope of the protection subject of the present invention is limited to the following examples, and all technologies realized based on the content of the present invention belong to the scope of the present invention. Well-known methods, procedures, procedures and elements have not been described in detail in order to avoid obscuring the essence of the present invention.

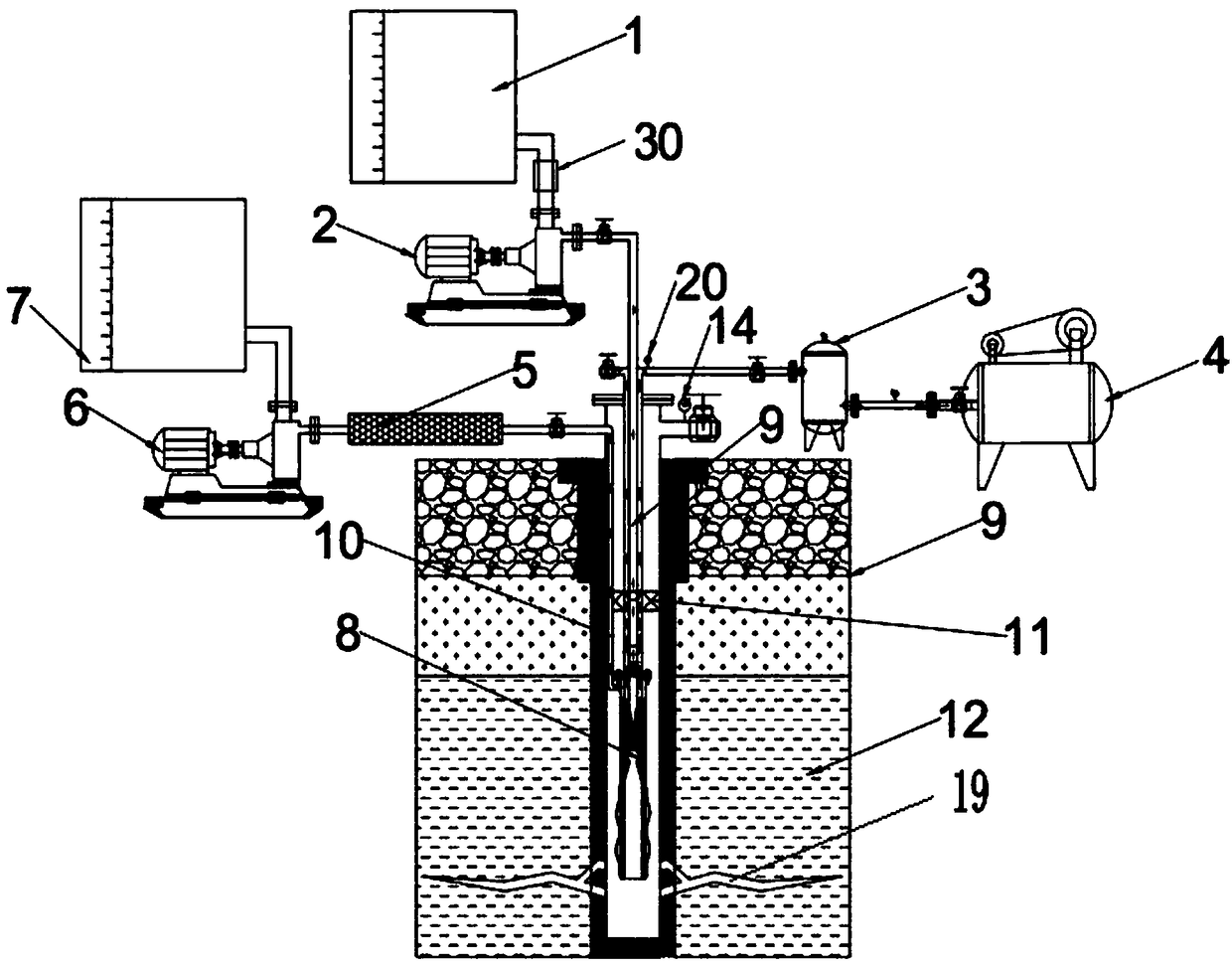

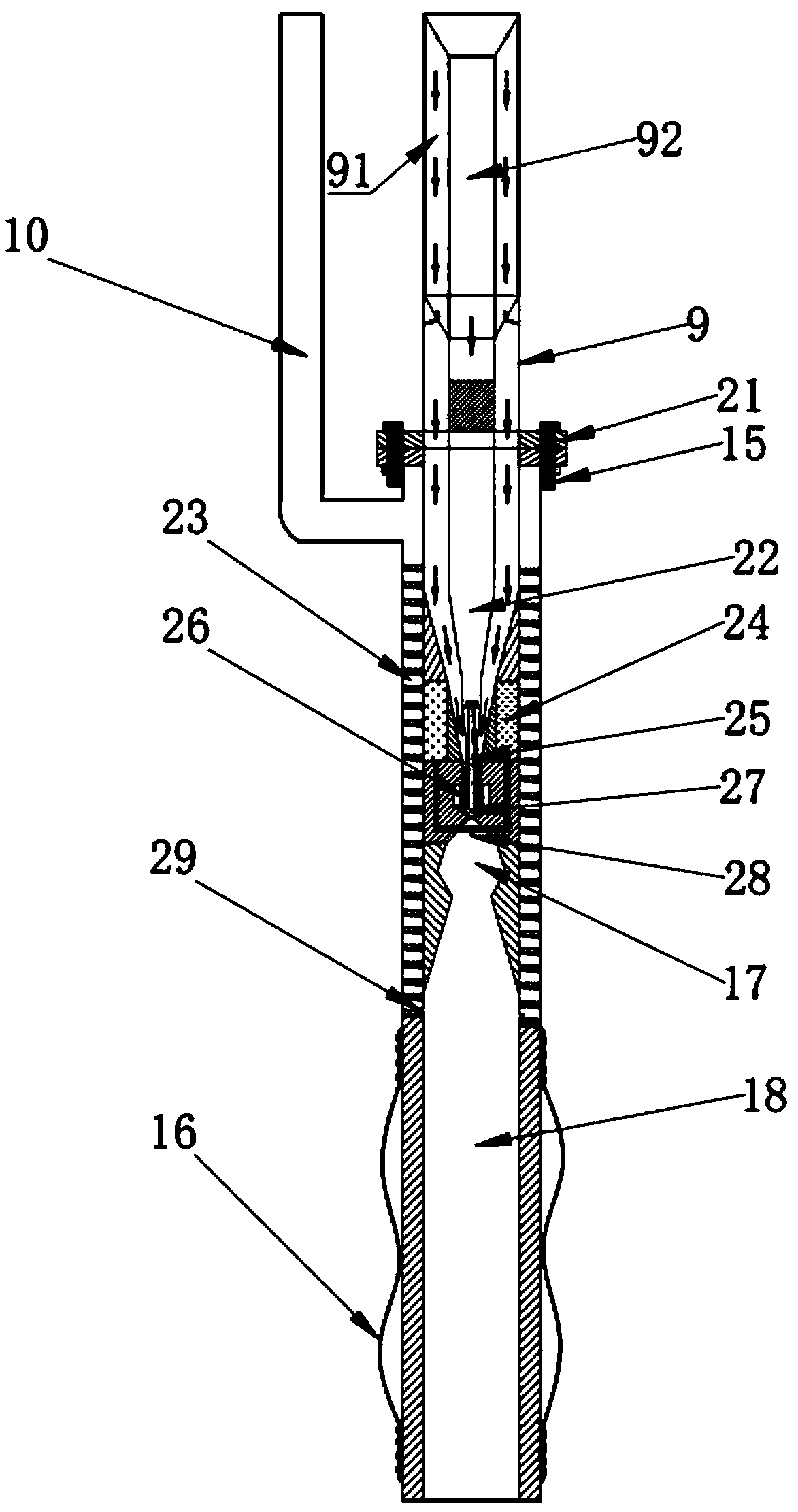

[0022] The present invention proposes a system for in-situ cracking of oil shale, such as figure 1 and figure 2 As shown, the system includes a first oil tank 1, an oil pump 2, a surge tank 3, an air compressor 4, a filter 5, a water pump 6, a water tank 7, a super-combustion heater 8, a double-walled oil pipe 9, a water guide channel 10 and The thermal packer 11, one end of the oil pump 2 is communicated with the first oil t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com