Preparation method of emulsion pressure-sensitive adhesive and polarizer protective film

A protective film, hydraulic technology, applied in the direction of pressure-sensitive film/sheet, adhesive, film/sheet adhesive, etc., can solve the problems of environmental pollution, complex process, etc., to improve compatibility, stable performance, reduce The effect of the glue dispensing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

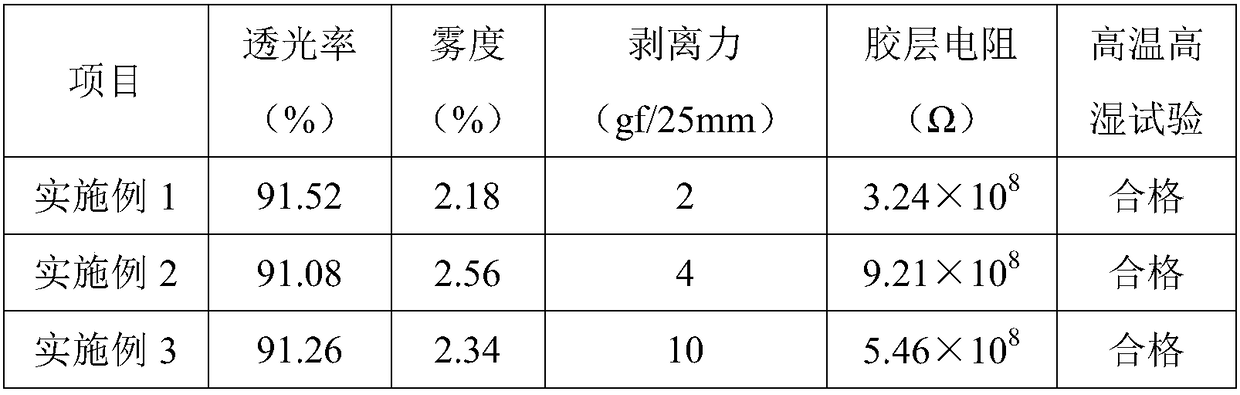

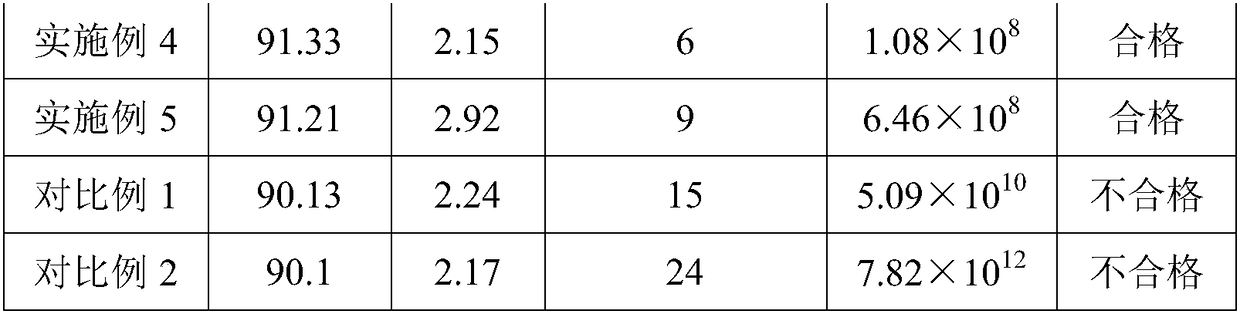

Examples

Embodiment 1

[0028] (1) 100 g of deionized water and 0.5 g of sodium vinyl sulfonate were stirred and mixed evenly to obtain a prefabricated solution;

[0029] (2) Weighing 20.1g of the prefabricated solution is used to dissolve 0.5g ammonium persulfate to obtain an initiator solution; 2g diacetone acrylamide, 15g isooctyl acrylate, 5g vinyl acetate, 4g 2-hydroxyethyl acrylate , 2.5g of zinc oxide with a particle diameter of 50nm modified by triethylvinylsilane, 0.5g of tin oxide with a particle diameter of 200nm modified by methylstyrene silane, stirred and mixed evenly to obtain an intermediate solution;

[0030] (3) Add 0.5g sodium bicarbonate and 2.9g intermediate solution to the remaining pre-preparation solution, pre-emulsify for 20 minutes, raise the temperature to 85°C, and add the initiator solution dropwise, until the pre-emulsion turns blue, add the remaining initiator solution dropwise at the same time agent solution and the remaining intermediate solution, after both additions...

Embodiment 2

[0033] (1) 150g of deionized water, 0.5g of sodium vinylsulfonate, and 0.5g of sodium p-styrenesulfonate were stirred and mixed evenly to obtain a prefabricated solution;

[0034] (2) Weighing 45.2g of the prefabricated solution is used to dissolve 0.75g ammonium persulfate and 0.75 potassium persulfate to obtain an initiator solution; , 15g lauryl methacrylate, 6g n-butyl methacrylate, 6g vinyl acetate, 2g-2-hydroxyethyl acrylate, 5g-2-hydroxypropyl methacrylate, 0.3g methyl styrene silane modified Zinc oxide with a particle size of 80nm, 0.37g tin oxide with a particle size of 100nm modified by triethylvinylsilane, 0.13g tin oxide with a particle size of 250nm modified with methylvinyldiethoxysilane, 0.2g formazan Zinc oxide with a particle size of 300nm modified by phenylvinyl styrene silane was stirred and mixed evenly to obtain an intermediate solution;

[0035](3) Add 0.4g sodium bicarbonate, 0.6g ammonium bicarbonate and 10.04g intermediate solution to the remaining pr...

Embodiment 3

[0038] (1) 125 g of deionized water, 0.5 g of sodium vinyl sulfonate, 0.5 g of sodium p-styrene sulfonate, and 0.5 g of sodium methylpropene sulfonate were mixed rapidly to obtain a prefabricated solution;

[0039] (2) Weigh 25.3g of the prefabricated solution for dissolving 1.25g of potassium persulfate to obtain an initiator solution; 3g of diacetone acrylamide, 30g of lauryl methacrylate, 15g of n-butyl methacrylate, 6g of methacrylic acid -2-hydroxypropyl ester, 0.5g zinc oxide with a particle size of 50nm modified by triethylvinylsilane, 0.5g tin oxide with a particle size of 70nm modified by methylstyrene silane, 0.5g methylvinyl diethyl Oxysilane-modified zinc oxide with a particle size of 100nm, 0.25g methylvinyldiethoxysilane-modified tin oxide with a particle size of 200nm, 0.25g methylstyrene silane-modified zinc oxide with a particle size of 250nm , quickly stir and mix evenly to obtain the intermediate liquid;

[0040] (3) Add 1.25g of ammonium bicarbonate and 8....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com