Preparation method for mesoporous silica nano hemisphere material

A mesoporous silica and hemispherical technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of small adjustable range of pore diameter, limited growth substrate, small pore diameter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

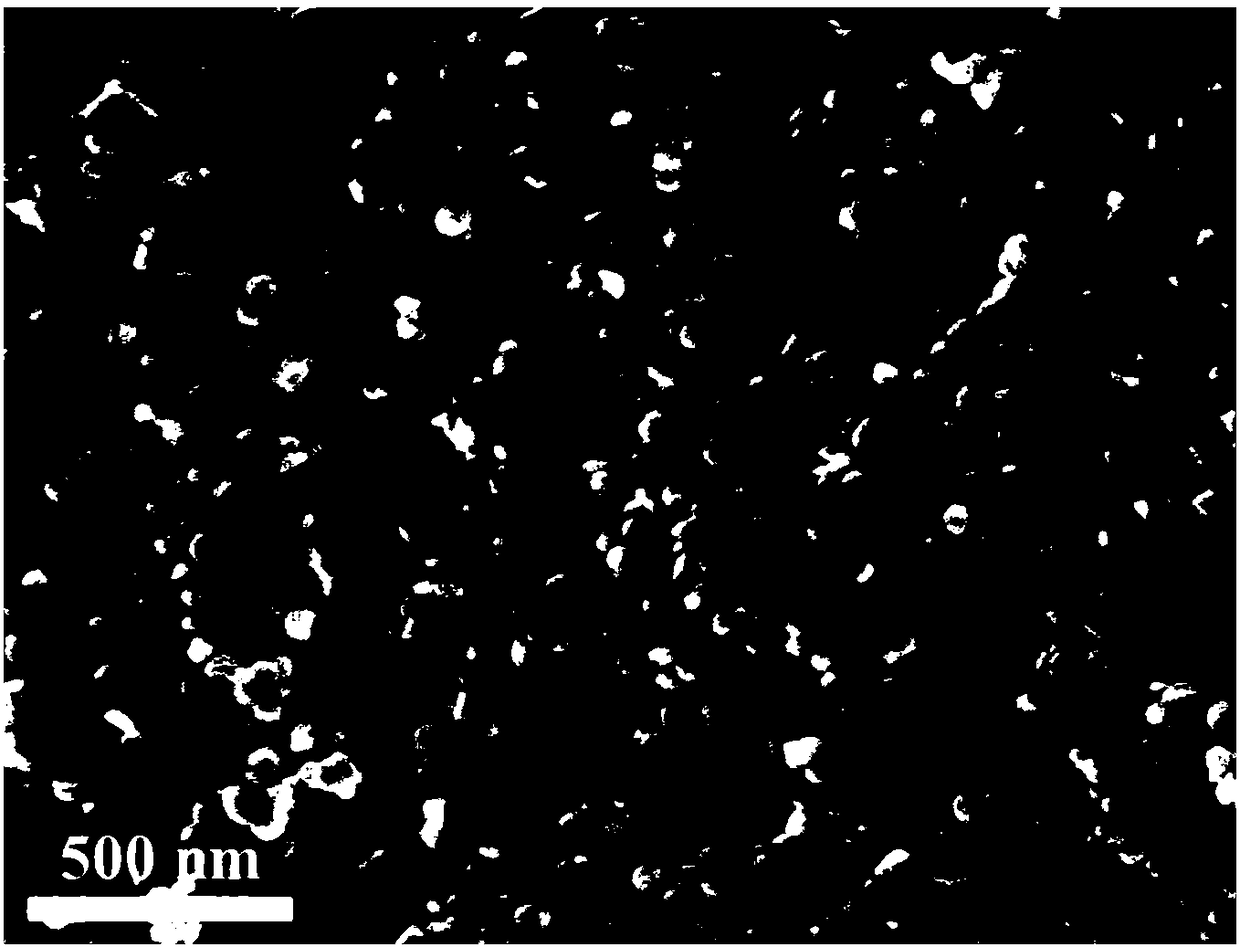

[0035] A mesoporous silica nano-hemisphere material and a preparation method thereof, comprising:

[0036] (1) Water phase system:

[0037] Dissolve 2.0g of cetyltrimethylammonium chloride and 0.075mL of triethanolamine in 20mL of deionized water successively, stir evenly to form a colorless and transparent solution; put the colorless and transparent solution into the reactor, and then add 30mg of graphene oxide, then ultrasonically dispersed, and continued to stir for 0.5h to obtain a black solution;

[0038] Oil phase system: Dissolve ethyl orthosilicate in cyclohexane to obtain 7mL organic solution; the concentration of ethyl orthosilicate is 10wt%;

[0039] Add the organic solution dropwise on top of the black solution to form an oil-water two-phase layered system;

[0040] (2) reacting the two-phase layered system in the step (1) in an oil bath at a temperature of 60° C. for 5 h; obtaining a mesoporous hemisphere grown on a graphene substrate;

[0041] (3) Place the ab...

Embodiment 2

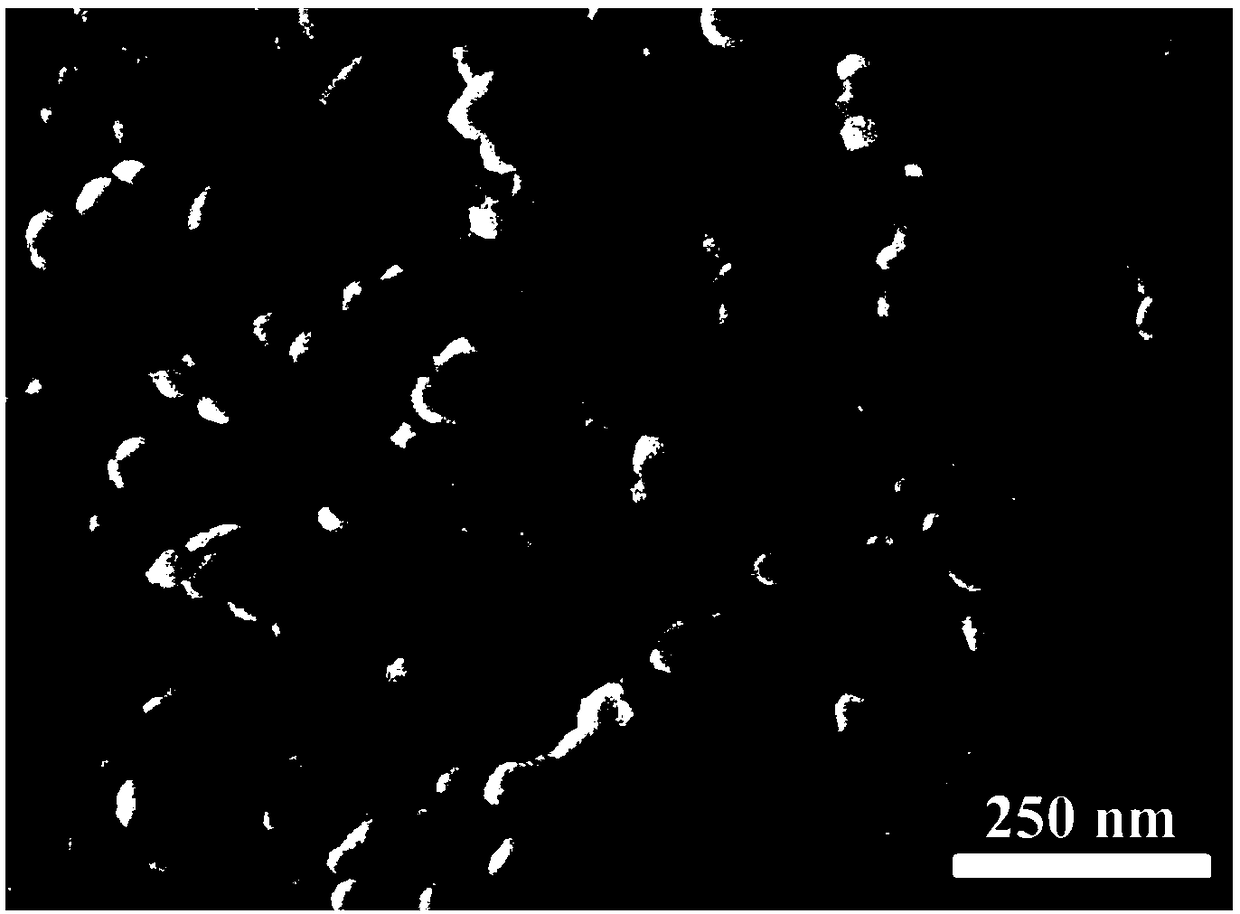

[0044] A mesoporous silica nano-hemisphere material and a preparation method thereof, comprising:

[0045] (1) Water phase system:

[0046] Dissolve 0.1g of cetyltrimethylammonium chloride and 0.075mL of triethanolamine in 20mL of deionized water successively, stir evenly to form a colorless and transparent solution; put the colorless and transparent solution into the reactor, and then add 5mg of graphene oxide, then ultrasonically dispersed, and continued to stir for 0.5h to obtain a black solution;

[0047] Oil phase system: Dissolve fumed silica in n-hexane to obtain 8mL organic solution; the concentration of fumed silica is 2.5wt%;

[0048] Add the organic solution dropwise on top of the black solution to form an oil-water two-phase layered system;

[0049] (2) reacting the two-phase layered system in the step (1) in an oil bath at a temperature of 60°C for 5h; obtaining a mesoporous hemisphere grown on a graphene substrate;

[0050] (3) Place the above-mentioned mesopo...

Embodiment 3

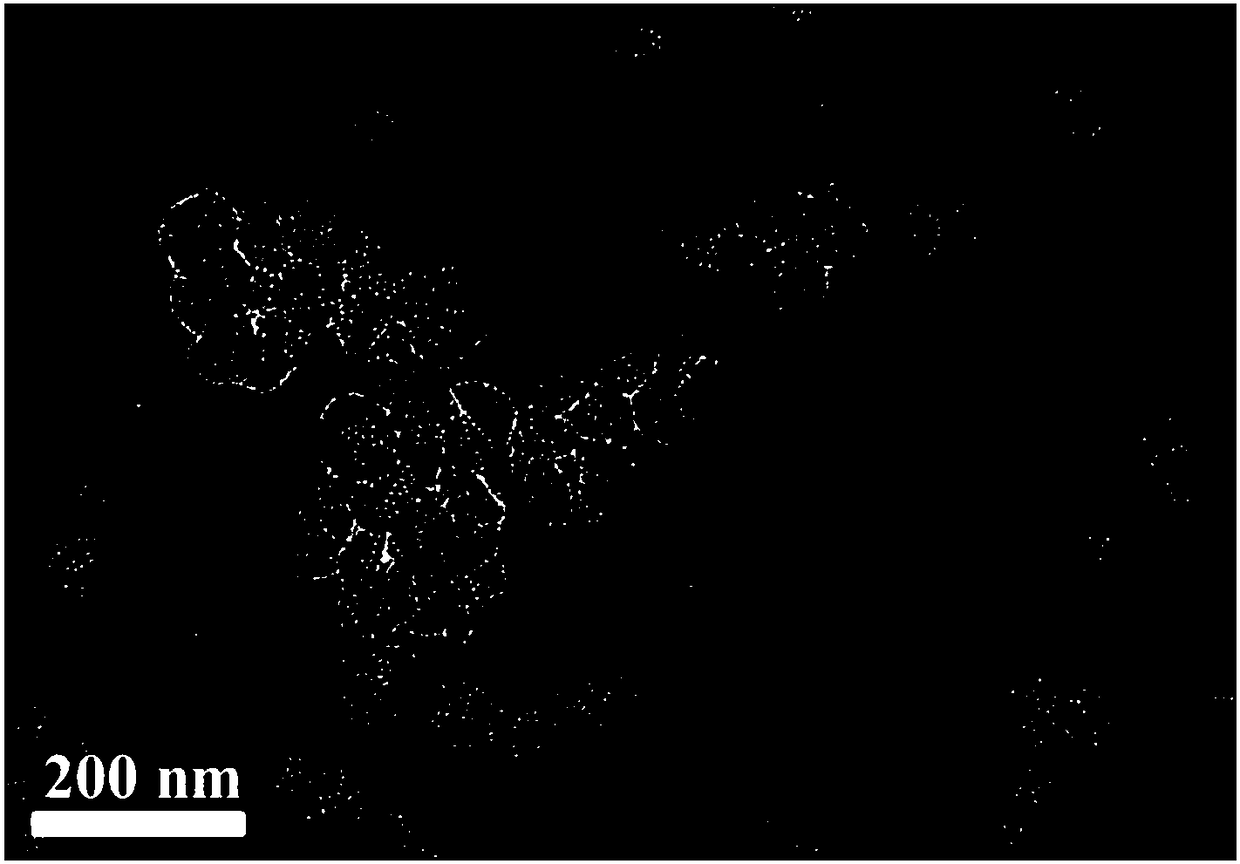

[0053] A mesoporous silica nano-hemisphere material and a preparation method thereof, comprising:

[0054] (1) Water phase system:

[0055]Dissolve 4.0g of octadecyltrimethylammonium chloride and 0.15mL of dodecylamine successively into 20mL of deionized water, stir evenly to form a colorless and transparent solution; put the colorless and transparent solution into the reactor, and then Add 200 mg of reduced graphene oxide and graphene, then ultrasonically disperse, and continue stirring for 1.0 h to obtain a black solution;

[0056] Oil phase system: Dissolve ethyl orthosilicate in n-hexane to obtain 8mL organic solution; the concentration of the solvent is 40wt%;

[0057] Add the organic solution dropwise to the top of the black solution to form an oil-water two-phase layered system, and continue to react under this condition for 10 h;

[0058] (2) React the two-phase layered system in step (1) in an oil bath at a temperature of 80°C; obtain mesoporous hemispheres grown on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com