Preparation method of composite magnesium-aluminum-based hydrogen storage material

A hydrogen storage material, magnesium-aluminum-based technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of high density of hydrogen storage materials, disadvantage of lightweight fuel cell development, slow hydrogen release, and high hydrogen release temperature. To achieve the effect of improving oxidation stability and increasing the reaction contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

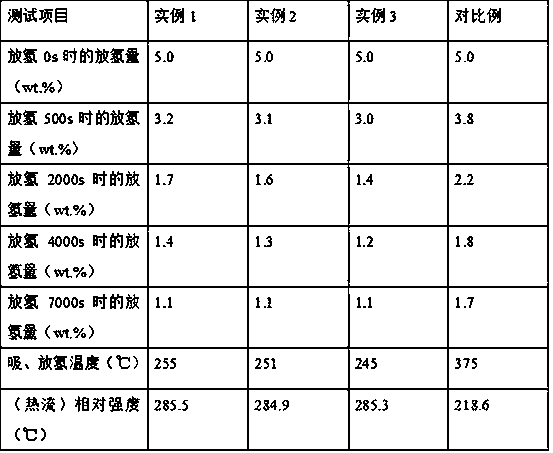

Examples

example 1

[0027]Cut the magnesium metal into 5cm×5cm×10cm magnesium blocks, use the magnesium block as the anode, and the carbon rod as the cathode, and vacuum the DC arc plasma equipment to 5×10 -2 Pa, then fill it with argon gas to the set pressure of 0.8MPa, feed cooling water into the DC arc plasma equipment, control the temperature of the cooling water to 20°C, and the pressure of the cooling water to 4.2MPa; start the DC arc plasma equipment, Control the arcing current to 80A, let it stand for 1h, collect the magnesium powder solidified in the DC arc plasma equipment to collect the inner wall, and obtain superfine magnesium powder, dissolve 4g of titanium chloride in 30mL of tetrahydrofuran, heat up to 50°C, Start the magnetic stirrer, start stirring with the rotating speed of 400r / min, treat that titanium chloride is all dissolved, obtain organometallic solution; Calculate in parts by weight, get 30 parts of manganese iron ore, 10 parts of rice husks, 8 parts of titanium powder an...

example 2

[0029] Cut the magnesium metal into 5cm×5cm×10cm magnesium blocks, use the magnesium block as the anode, and the carbon rod as the cathode, and vacuum the DC arc plasma equipment to 5×10 -2 Pa, then fill it with argon gas to the set pressure of 0.8MPa, feed cooling water into the DC arc plasma equipment, control the temperature of the cooling water to 23°C, and the pressure of the cooling water to 4.3MPa; start the DC arc plasma equipment, Control the arcing current to 90A, let it stand for 1.5h, collect the magnesium powder solidified in the DC arc plasma equipment and collect the inner wall to obtain ultrafine magnesium powder, dissolve 4.5g titanium chloride in 35mL tetrahydrofuran, and heat up to 60 ℃, start the magnetic stirrer, start stirring at a speed of 450r / min, and wait until the titanium chloride is completely dissolved to obtain an organic metal solution; in parts by weight, take 35 parts of manganese iron ore, 13 parts of rice husk, and 9 parts of titanium Put th...

example 3

[0031] Cut the magnesium metal into 5cm×5cm×10cm magnesium blocks, use the magnesium block as the anode, and the carbon rod as the cathode, and vacuum the DC arc plasma equipment to 5×10 -2 Pa, then fill it with argon gas to the set pressure of 0.9MPa, feed cooling water into the DC arc plasma equipment, control the temperature of the cooling water at 25°C, and the pressure of the cooling water at 4.5MPa; start the DC arc plasma equipment, Control the arcing current to 100A, let it stand for 2 hours, collect the magnesium powder solidified on the inner wall of the DC arc plasma equipment, and obtain superfine magnesium powder, dissolve 5g of titanium chloride in 40mL of tetrahydrofuran, and heat up to 70°C. Start the magnetic stirrer, start stirring with the rotating speed of 500r / min, treat that titanium chloride is all dissolved, obtain organometallic solution; Calculate by weight parts, get 40 parts of ferromanganese ore, 15 parts of rice husks, 10 parts of titanium powder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com