Vehicle, magnetic levitation clutch system, electric power steering system and control method

A technology of electric power steering and control method, which is applied to electric steering mechanism, power steering mechanism, steering mechanism, etc., can solve the problems of slow response speed and long separation time, and achieve short response period, energy saving, and energy consumption reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

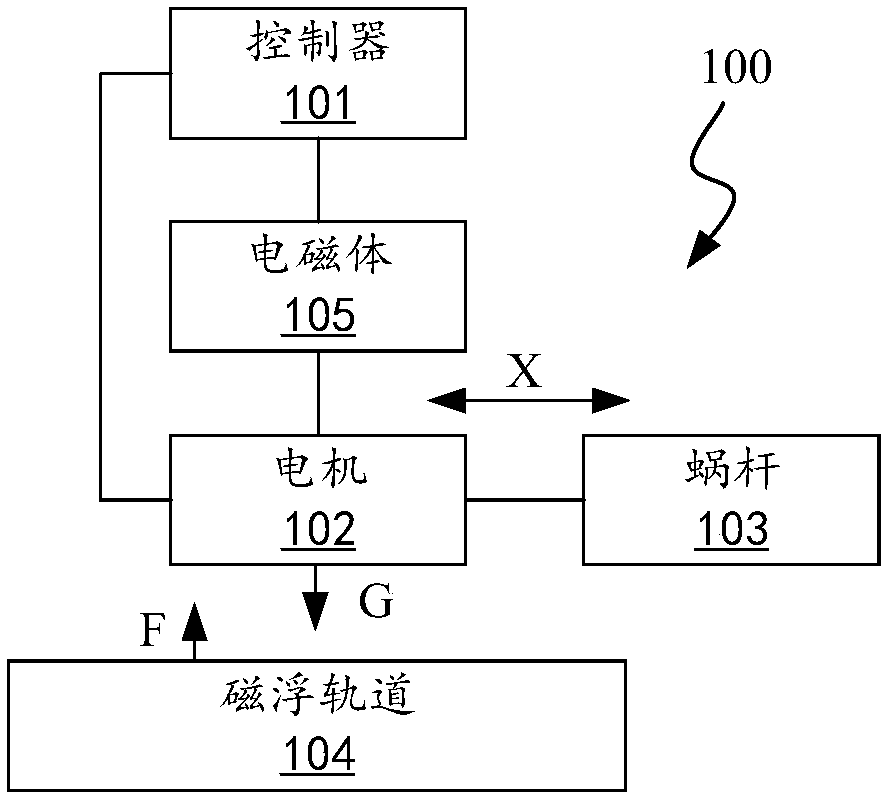

[0036] Please refer to figure 2 , image 3 , the first embodiment provides a maglev clutch system 100, including a controller 101, a motor 102 and a worm 103, a maglev track 104 for suspending the motor 102, and one of the housing of the motor 102 and the worm 103 is set There is an electromagnet 105, and the remaining one is set to be made of magnetically conductive material. The controller 101 circuit is connected with the electromagnet 105 and the motor 102, and is used to control the change of the magnetic field of the electromagnet 105 so that the motor 102 moves closer or farther along the maglev track 104. The direction of the worm 103 is moved in suspension, so that the motor 102 and the worm 103 are in a combined state or in a separated state.

[0037] Please refer to figure 2 The electromagnet 105 may be disposed at one end of the housing of the motor 102, specifically, may surround a circumferential surface fixedly disposed on the housing of the motor 102 or par...

Embodiment 2

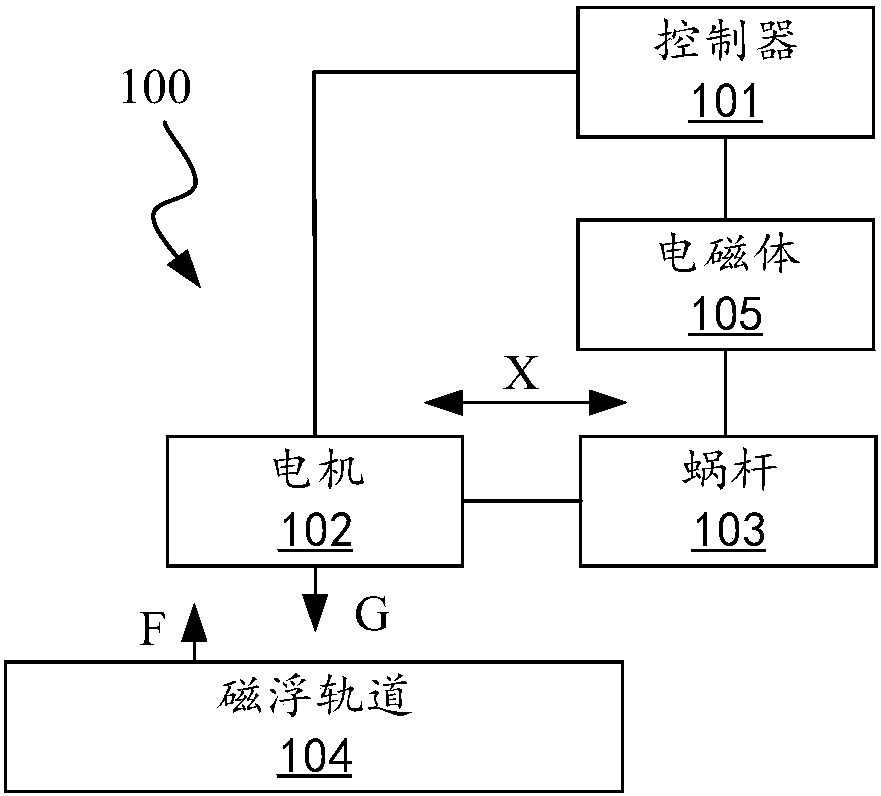

[0041] The second embodiment provides a maglev clutch system 100 . Please refer to Figure 4 , the second embodiment is improved on the basis of the first embodiment, the difference is that the housing of the motor 102 and the worm 103 are provided with electromagnets 105, to replace one of the housing of the motor 102 and the worm 103 as a guide A solution made of magnetic materials.

[0042] The control method of the maglev clutch system of the second embodiment is as follows: when the controller 101 feeds a current to the electromagnet 105, the two electromagnets 105 feed the current to generate a magnetic field; , the direction of the magnetic field generated by the two electromagnets 105 is opposite, the motor 102 and the worm 103 attract each other, and the motor 102 moves along the magnetic levitation track 104 to the direction close to the worm 103, so that the motor 102 and the worm 103 are in a combined state When the direction of the two electromagnets 105 connect...

Embodiment 3

[0045] The third embodiment provides a maglev clutch system 100 . Please refer to Figure 5 , the third embodiment is improved on the basis of the first or second embodiment, the difference is that the maglev clutch system 100 also includes an electromagnetic control module 106, the controller 101 is connected to the electromagnet 105 through the electromagnetic control module 106, The controller 101 controls the change of the magnetic field of the electromagnet 105 through the electromagnetic control module 106 to levitate the motor 102 along the magnetic levitation track 104 toward or away from the worm 103 , so that the motor 102 and the worm 103 are in a combined or separated state. That is, the electromagnetic control module 106 is used to replace the controller 101 to control the on or off of the electric current of the electromagnet 105 , and to control the direction of the electric current of the electromagnet 105 to control the direction of the magnetic field of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com