Microplastics flotation separation device and application method thereof

A separation device and technology for microplastics, applied in the restoration of polluted soil, etc., can solve the problem of difficulty in extracting microplastics, and achieve the effects of strong environmental friendliness, effective separation, and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

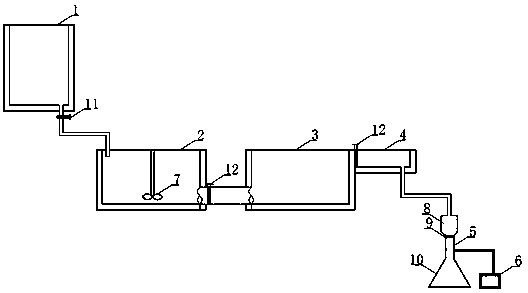

[0019] Such as figure 1 As shown, the microplastic flotation separation device of the present invention includes a high-level water tank 1, a reactor 2, a sedimentation tank 3, an open channel 4 and a filter 5 connected in sequence; wherein, distilled water is stored in the high-level water tank 1, and at the outlet of the high-level water tank 1 A valve 11 is provided; the reactor 2 is provided with an agitator 7, and the outlet of the reactor 2 is provided with a timing valve 12; the entrance of the open channel 4 is provided with a timing valve 12, which can control the precipitation time of the liquid; There is a filter membrane 9, the filter membrane 9 is a nitrocellulose filter membrane, the filter 5 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com