Extraction method of active components of lycium barbarum and application

An extraction method and a technology of active ingredients, which are applied in the field of extracting active ingredients of wolfberry, can solve the problems of low extraction rate of polysaccharides and flavonoids, large amount of residual waste, difficult to handle, etc., and achieve the effects of improved utilization rate, small size, and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

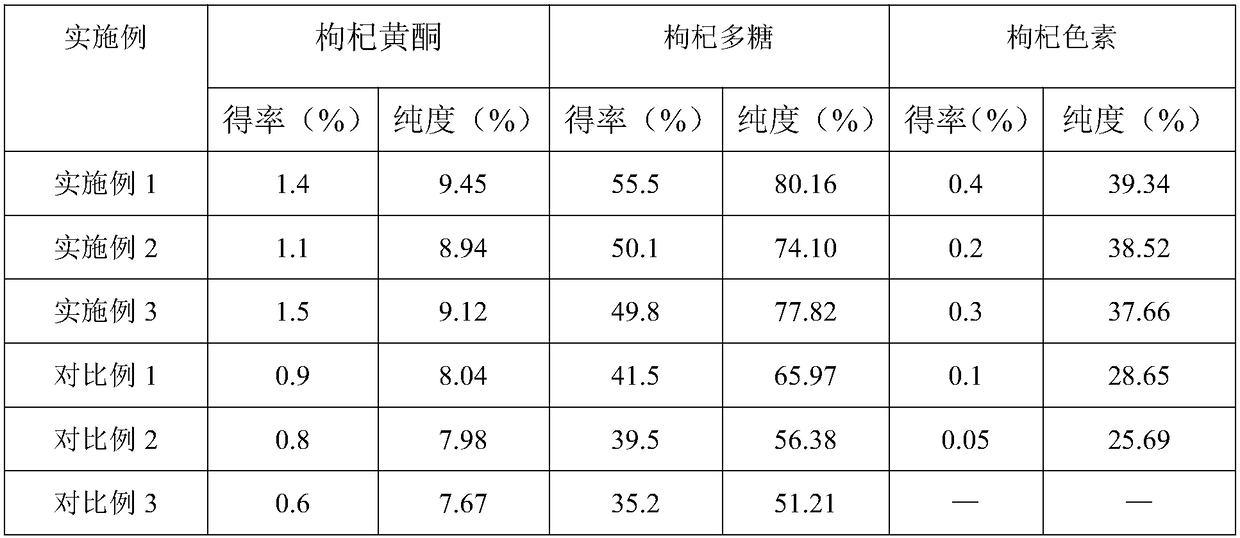

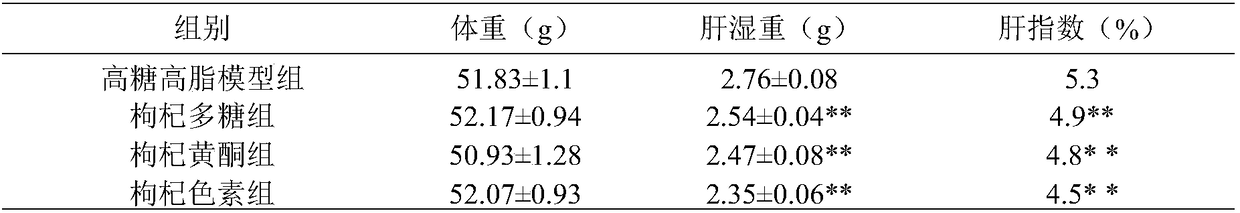

Embodiment 1

[0035] 1) Grind black wolfberry after freeze-drying at -10~-20°C into a powder with a particle size of 30 mesh, mix black wolfberry powder with distilled water at a mass volume ratio of 1:20g / ml, and perform ultrasonic extraction at a temperature of 70 ℃, the extraction time is 1.5h, and then filtered to obtain the water-extracted filtrate and the water-extracted filter residue;

[0036] 2) The water-extracted filter residue was mixed with absolute ethanol at a mass volume ratio of 1:10 g / ml, and then microwave-extracted at room temperature for 1.5 hours to obtain ethanol-extracted mixture I;

[0037] 3) After the water extraction filtrate is concentrated and dried, it is mixed with absolute ethanol at a mass volume ratio of 1:5 g / ml, and ultrasonically extracted at 70° C. for 0.5 h to obtain ethanol extraction mixture II;

[0038] 4) Filtering the ethanol extraction mixture I and the ethanol extraction mixture II respectively, mixing and concentrating the obtained two filtrat...

Embodiment 2

[0042] 1) Crush the black wolfberry after freeze-drying at -10~-20°C into a powder with a particle size of 40 mesh, mix the black wolfberry powder and distilled water at a mass volume ratio of 1:10g / ml, and then perform ultrasonic extraction at a temperature of 78 ℃, the extraction time is 2h, and then filtered to obtain the water-extracted filtrate and the water-extracted filter residue;

[0043] 2) The water-extracted filter residue was mixed with absolute ethanol at a mass volume ratio of 1:10 g / ml, and then microwave-extracted at room temperature for 2 hours to obtain ethanol-extracted mixture I;

[0044] 3) After the water extraction filtrate is concentrated and dried, it is mixed with absolute ethanol at a mass volume ratio of 1:6 g / ml, and ultrasonically extracted at 78°C for 1 hour to obtain ethanol extraction mixture II;

[0045] 4) Filtering the ethanol extraction mixture I and the ethanol extraction mixture II respectively, mixing and concentrating the obtained two ...

Embodiment 3

[0049] 1) Crush the black wolfberry after freeze-drying at -10~-20°C into a powder with a particle size of 50 mesh, mix the black wolfberry powder with distilled water at a mass volume ratio of 1:15g / ml, and then perform ultrasonic extraction at a temperature of 80 ℃, the extraction time is 3h, and then filtered to obtain the water-extracted filtrate and the water-extracted filter residue;

[0050] 2) The water-extracted filter residue was mixed with absolute ethanol at a mass volume ratio of 1:15g / ml, and then microwave-extracted at room temperature for 2.5 hours to obtain ethanol-extracted mixture I;

[0051] 3) After the water extraction filtrate is concentrated and dried, it is mixed with absolute ethanol at a mass volume ratio of 1:10 g / ml, and ultrasonically extracted at 80°C for 1.2 hours to obtain ethanol extraction mixture II;

[0052] 4) Filtering the ethanol extraction mixture I and the ethanol extraction mixture II respectively, mixing and concentrating the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com