Milking and milk-storing system with waste-heat recovery and washing water sorted-collection functions

A waste heat recovery and flushing water technology, applied to milking devices, machines using waste heat, milk containers, etc., can solve problems such as waste, waste of energy consumption, and high energy consumption of cooling systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

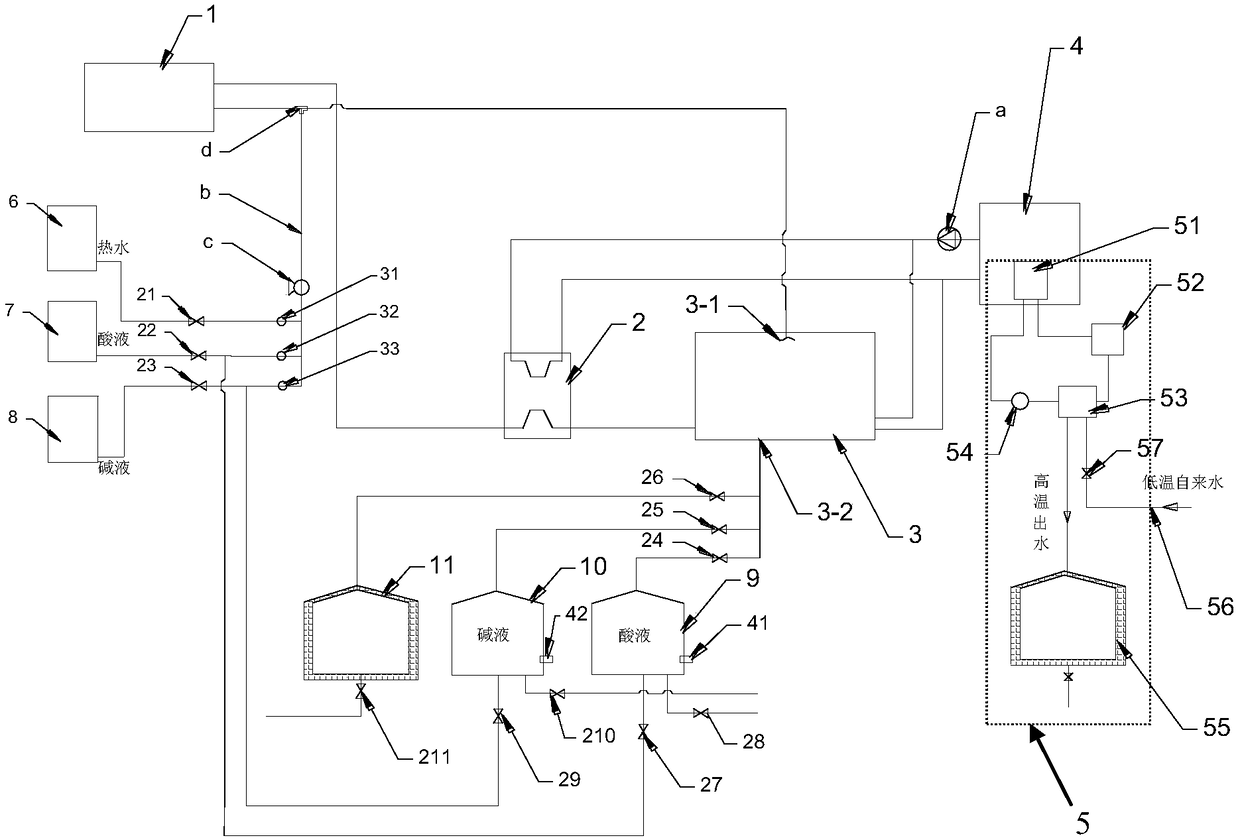

[0041] Referring to the accompanying drawings, a milking and storage system with waste heat recovery and washing water classification and collection functions, including milking machine end 1, primary cooling heat exchanger 2, milk storage tank 3, cooling water tank 4, cooling system with waste heat recovery function System 5, hot water supply tank 6, acid supply tank 7, lye supply tank 8, acid solution collection tank 9, lye solution collection tank 10 and hot water collection tank 11, milking machine end 1 adopts 2×6 fish Bone-type milking console, the milk outlet pipeline at the milker end is connected to the milk storage tank 3 through the primary cooling heat exchanger 2, and the milk storage tank is a horizontal water-cooled milk storage tank (the milk storage tank has cooling water layer, the cooling water layer is provided with a cooling water inlet and a cooling water return port).

[0042] The cooling water inlet and the cooling water return port of the primary cooli...

Embodiment 2

[0055] Furthermore, since the strength of the acid and alkali solution after washing is reduced, in order to ensure the cleaning effect, the acid and alkali solution collected twice can be cleaned twice in the next time.

Embodiment 3

[0057] Further, since the strength of the acid and lye after washing is reduced, in order to ensure the cleaning effect, the acid solution collected in the acid solution collection tank and the original acid solution in the acid solution supply tank can be used to clean the acid solution at the same time, and the alkali solution can be used to clean the acid solution. The lye collected in the lye collection tank and the original lye in the lye supply tank are cleaned by lye at the same time. That is, during acid flushing, when opening the seventh electric control valve 27, pump c and the fourth electric control valve 24, also open the second electric control valve 22; , pump c and the fifth electronically controlled valve 25, the third electronically controlled valve 23 is also opened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com