Gondola device

一种升降装置、驱动装置的技术,应用在房屋结构支承、发动机、风能发电等方向,能够解决结构复杂、加工性、经济性、操作性不利、水平维持困难等问题,达到增大作业面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

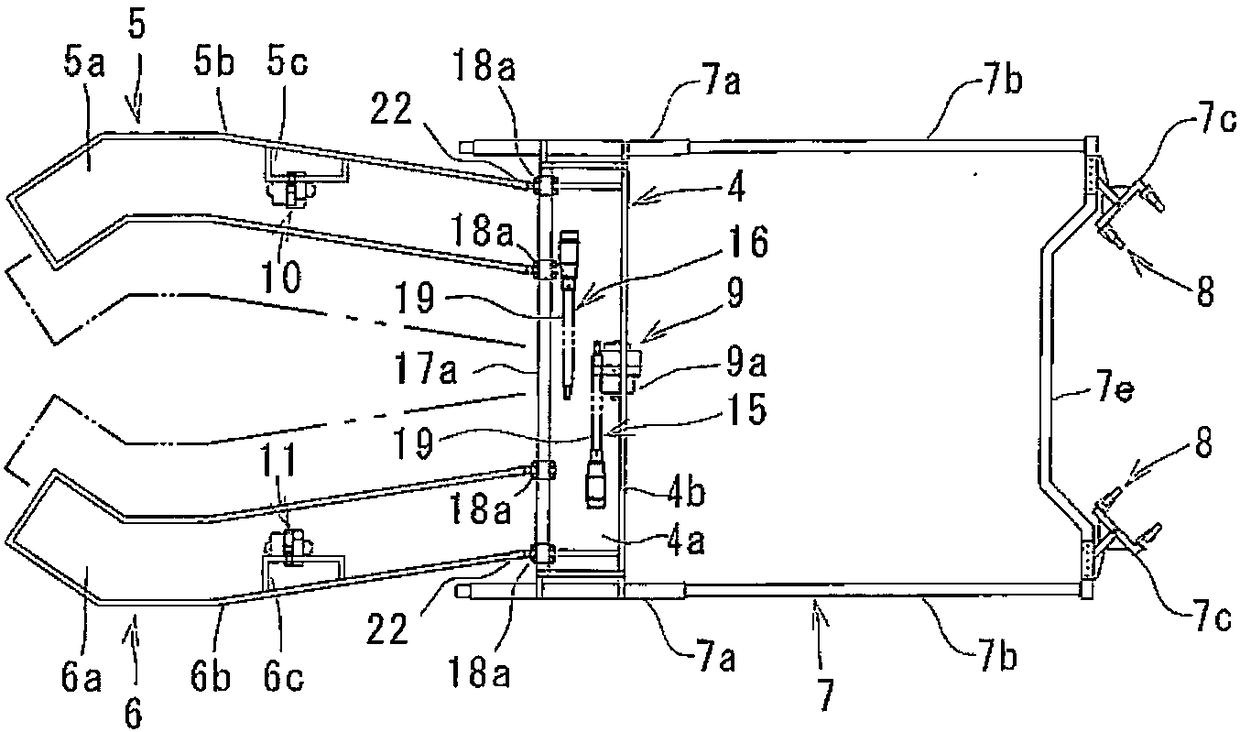

[0044] Hereinafter, an embodiment of the present invention will be described based on the drawings. like Figure 5 As shown, the present invention is applied to the maintenance of a wind power generation device having a columnar tower 1, a nacelle 2 mounted on the tower 1, and blades 3 rotatably arranged on the nacelle 2, and is particularly suitable for performing maintenance on the blades 3 thereof. Basket device A for maintenance work.

[0045] That is, the hanging basket device A is as Figure 5 As shown, the pedal frames 4, 5, and 6 lowered from the three pulling ropes 12, 13, and 14 lowered from the car 2 are lowered from the ground by using a known elevator such as a circulation type that is wound with the pulling ropes 12, 13, and 14. The position lifts to position B in the middle or position A above. For example, the pedal frames 4, 5, 6 are stopped at the intermediate position B, the upper position A, etc., and maintenance operations such as painting and repairing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com