Stannic selenide/graphene nanoplatelet composite material as well as preparation method and application thereof

A few-layer graphene, composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems affecting the electrochemical performance of materials, electrode material shedding, electrode material pulverization, etc., to achieve easy mass production, cost Low, improve the effect of ion transport and electronic conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add tin powder, selenium powder and expanded graphite raw material powder into the ball mill tank and mix, wherein the mass fraction of expanded graphite is 30%, the molar ratio of tin powder and selenium powder is 1:1, and the ball powder mass ratio of grinding balls to raw materials is 50% : 1, conduct dielectric barrier discharge plasma-assisted high-energy ball milling for 10 hours, the discharge gas medium is argon, and the pressure in the tank is 0.1Mpa. After ball milling, a tin selenide / few-layer graphene composite was obtained.

[0035] Among them, the dielectric barrier discharge plasma-assisted high-energy ball milling steps in this embodiment are:

[0036] (1) In the ball mill jar, load grinding balls and proportioned tin powder, selenium powder and expanded graphite;

[0037] (2) Vacuumize the ball mill tank by a vacuum pump, then fill in the discharge gas medium such as argon, helium or a mixture of inert gases, so that the pressure in the ball mill tank ...

Embodiment 2

[0045] The difference from Example 1 is that the ball milling time is 20h.

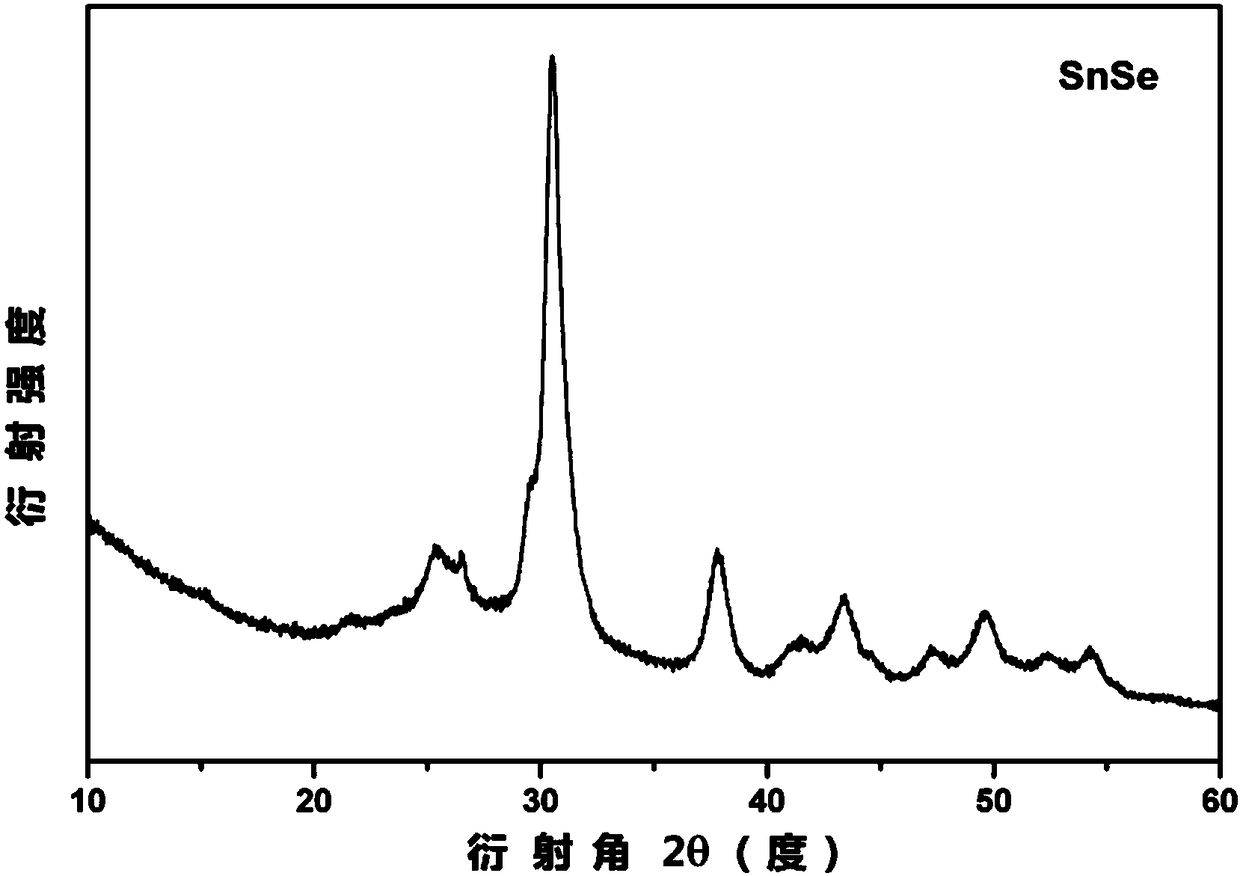

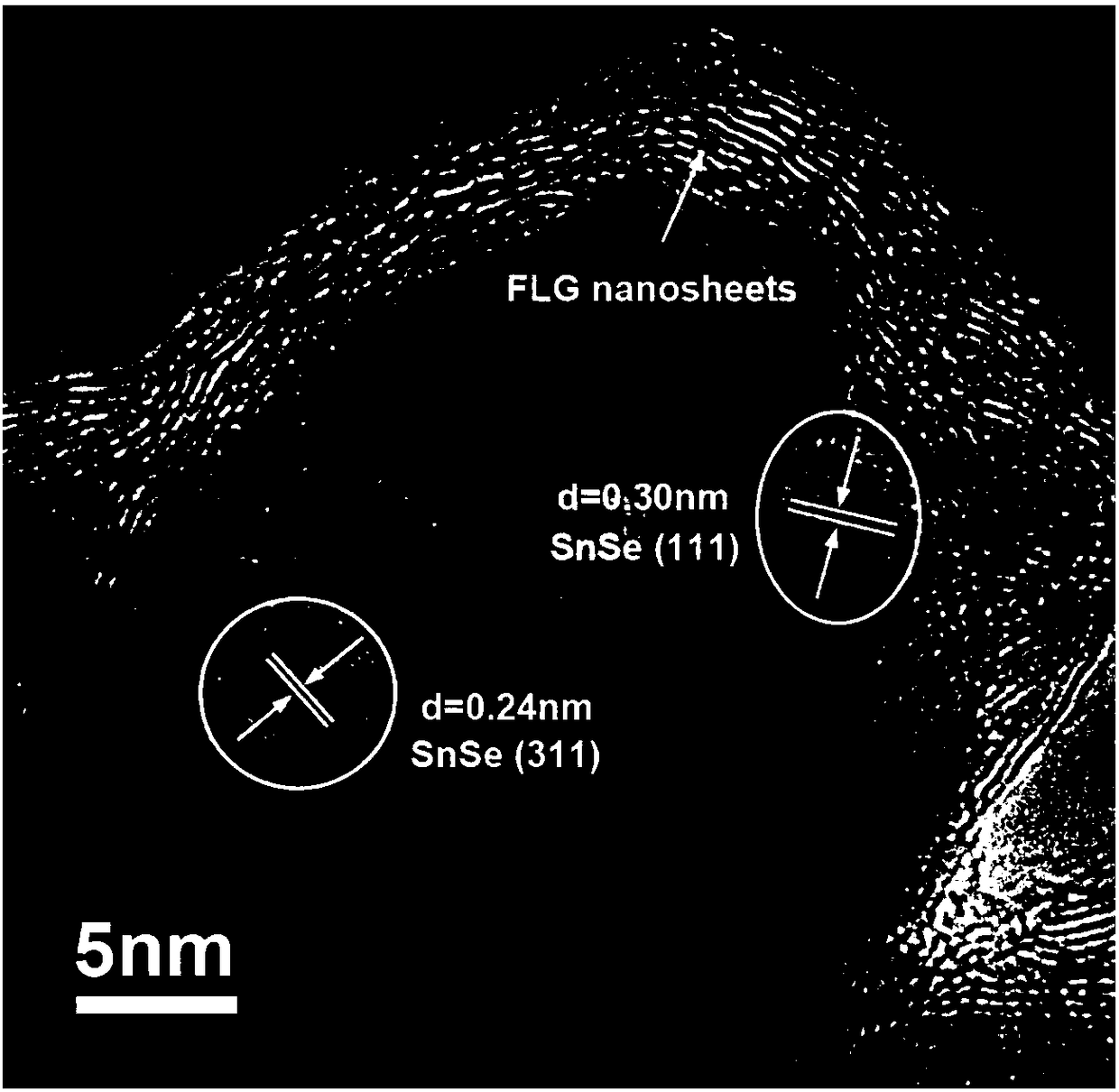

[0046] After ball milling, tin and selenium react to form tin selenide, the XRD picture is as follows figure 1 shown. SEM figure and HRTEM figure of the tin selenide / few-layer graphene composite material prepared in the present embodiment are respectively as follows figure 2 and image 3 shown by figure 2 and image 3 It can be seen that nanocrystalline tin selenide is uniformly coated in few-layer graphene.

[0047] The composite material prepared in this embodiment is made into the negative electrode sheet of lithium ion battery and the battery is assembled at 0.2A g -1 The rate of charge and discharge is between 0 and 2.5V, such as Figure 4 As shown, the first discharge specific capacity is 1360mAh g -1 , the specific capacity of the first charge is 868mAh g -1 , the first Coulombic efficiency is 63.8%, and after 200 cycles, the capacity is still 830mAh g -1 . High rate charge and discha...

Embodiment 3

[0050] The difference from Example 2 is that the ball milling time is 30h. After ball milling, a tin selenide / few-layer graphene composite was obtained.

[0051] The composite material prepared in this embodiment is made into the negative electrode sheet of lithium ion battery and the battery is assembled at 0.2A g -1 The charge-discharge cycle is carried out between 0 and 2.5V, and the first reversible specific capacity of SnSe@FLG is 766.5mAh g -1 , after 200 cycles, the reversible specific capacity dropped to 596.8mAh g -1 .

[0052] The prepared composite material was made into a negative electrode sheet of a sodium ion battery and the battery was assembled at 0.2A g -1 The charge-discharge cycle is carried out between 0 and 3V, and the first reversible specific capacity of SnSe@FLG is 396.5mAh g -1 , after 200 cycles, the reversible specific capacity dropped to 308.6mAh g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com