Method for treating dust in underground coal mine roadway driving

An underground roadway and dust technology, which is applied in mine/tunnel ventilation, drilling equipment and methods, dust prevention, etc., can solve the problems of low efficiency, prone to disaster accidents, and large pollution, so as to improve the construction environment and avoid dust and gas disaster accidents, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

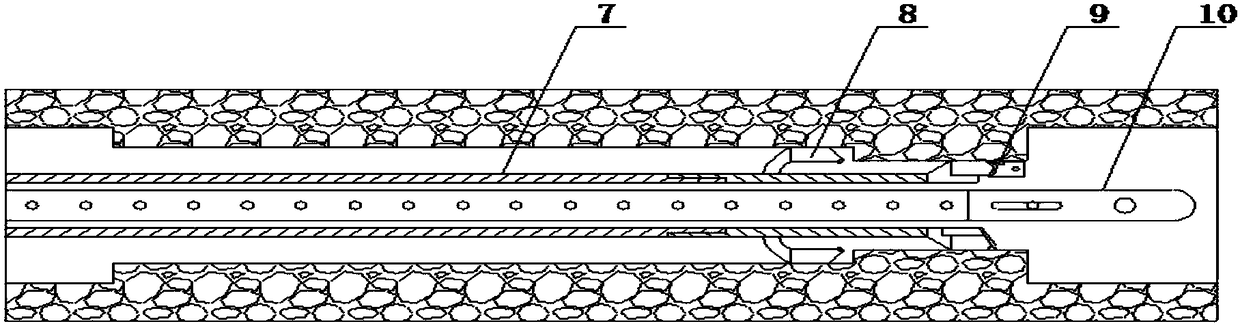

[0031] Such as Figure 4 As shown, the coal mine underground roadway excavation negative pressure ventilation and dust suction construction process method of the present invention comprises the following steps:

[0032] Construction preparation steps: According to the pre-excavation space range and geological data of the roadway, the drilling trajectory of the directional and penetrating tunnel is precisely designed. The layout and extension of the central connection line of the excavation roadway.

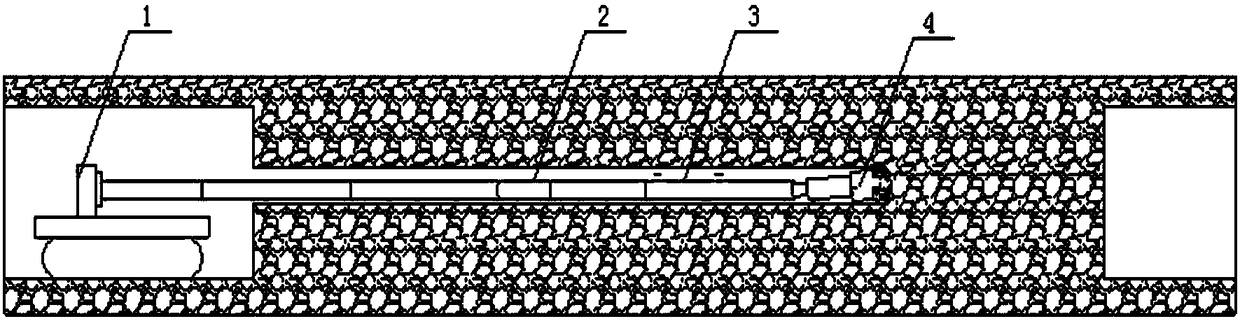

[0033] Hole opening step: use drilling rig 1, flat-bottomed full-face drill bit and outer flat drill pipe, and drill 12-15m in rotation according to the design opening parameters.

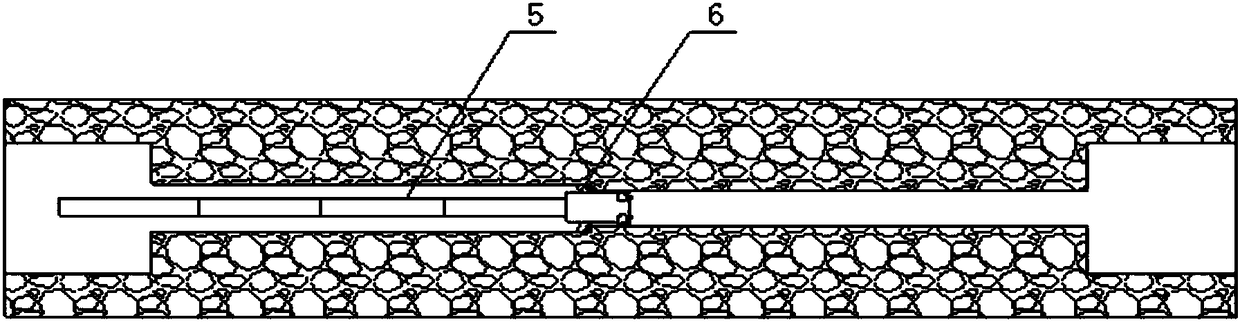

[0034] The construction steps of directional pilot hole drilling: put in the measurement-while-drilling system 2, the screw motor deflection drilling tool 3 and the directional drill bit 4, and conduct directional drilling according to the design trajectory of the drilling hole. , azimuth, tool face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com