An Intelligent Multifunctional Paper Machine Broken Paper Processing Classification System

A technology for processing sorting and paper machines, applied in paper machines, paper making, textiles and paper making, etc., can solve the problems of not having the function of storing and transferring broken paper, low degree of intelligent control, and not rich in use functions, etc. function, guarantee the quality of papermaking, and increase the effect of detection safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

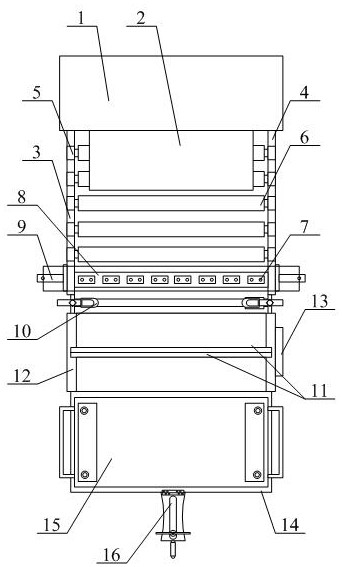

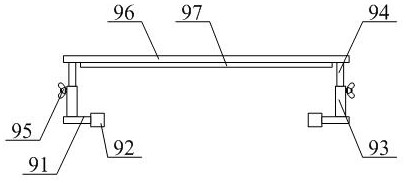

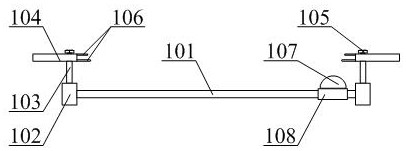

[0065] as attached figure 1 to attach Figure 7 shown

[0066] The present invention provides an intelligent multi-function broken paper processing and classification system for a paper machine, which includes a paper machine body 1, paper to be detected 2, a left bushing 3, a right bushing 4, a conventional bearing 5, a transmission roller 6, and a damage detector 7. Fixed seat 8, adjustable shading plate structure 9, automatic paper clamping claw structure 10, automatic opening and closing door 11, broken paper collection box 12, intelligent cabinet 13, placing table 14, paper transfer anti-falling plate structure 15 and take-out Paper device structure 16, the paper to be detected 2 is arranged at the outlet of the lower middle position of the paper machine body 1; the left liner 3 longitudinal bolts are installed on the lower left side of the paper machine body 1; the right liner 4 The longitudinal bolts are installed on the lower right side of the paper machine body 1; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com