A Feather Elasticity Tester

A tester, elastic technology, applied in the field of testing equipment, can solve problems such as feather difficulties, and achieve the effect of fast clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

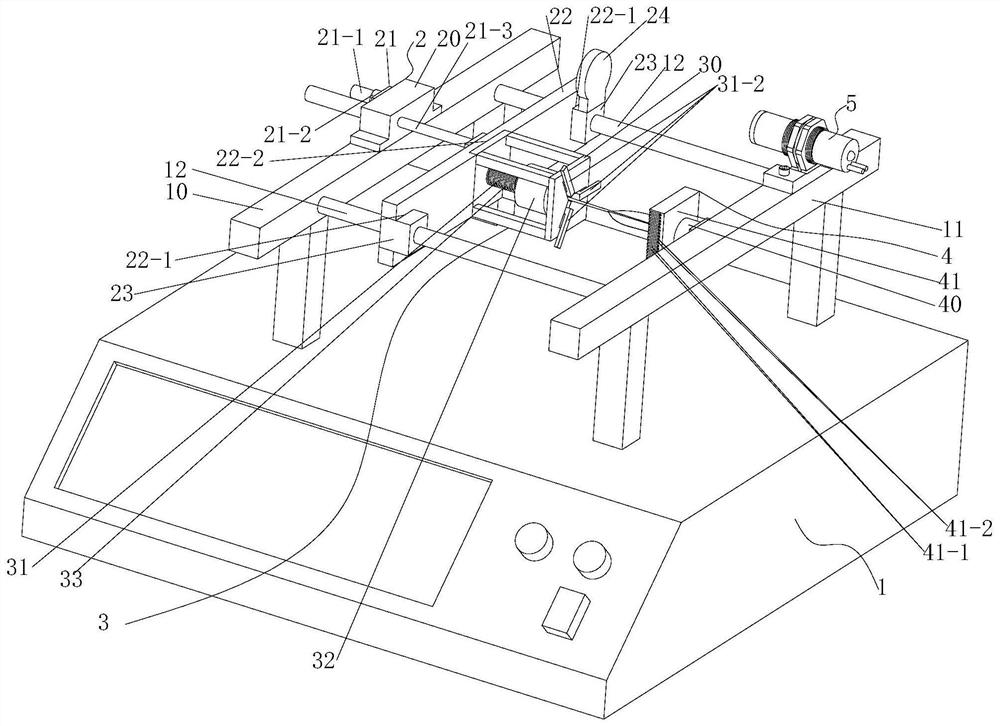

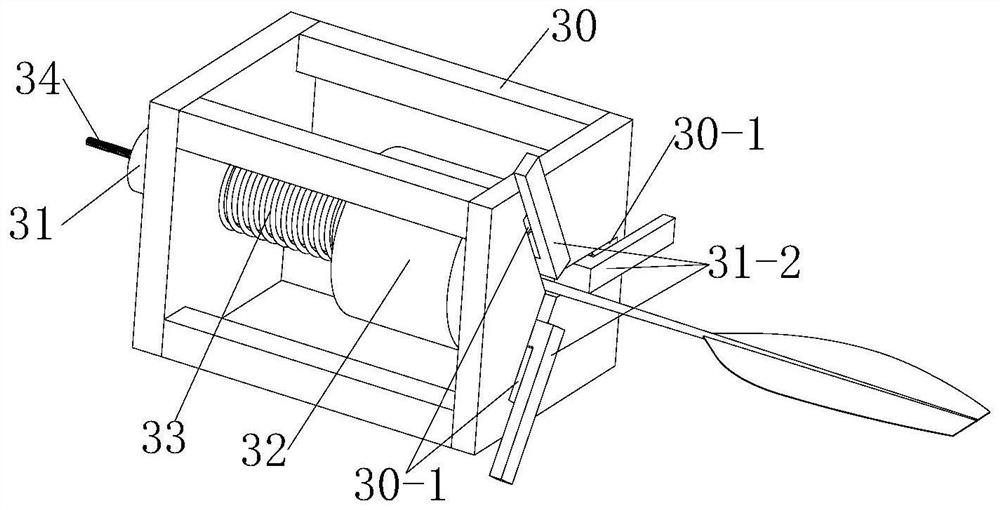

[0041] Refer to attached figure 1 As shown, first hold the tapered sleeve 32, push the tapered sleeve 32 back, and further compress the compression spring 33, so that the locking of the tapered sleeve 32 to the chuck 31-1 is released, and then the hair stem of the feather Insert in three collets 31-1, and make hair stem insert the threaded hole of clamping sleeve 31 centers, after the depth of insertion is moderate, loosen taper sleeve 32, under the effect of the elastic restoring force of stage clip 33, because The tapered sleeve 32 is provided with a conical hole, and the three chucks 31-1 are cut from a circular truncated body with a hole in the center, so the three chucks 31-1 are formed in the conical holes inside the tapered sleeve 32. Under the restraint of the feather, the hair stem of the feather is clamped; then the adjustment screw 34 is hand-screwed, so that the adjustment screw 34 will withstand the tail of the hair stem, and then according to the direction of the...

Embodiment 2

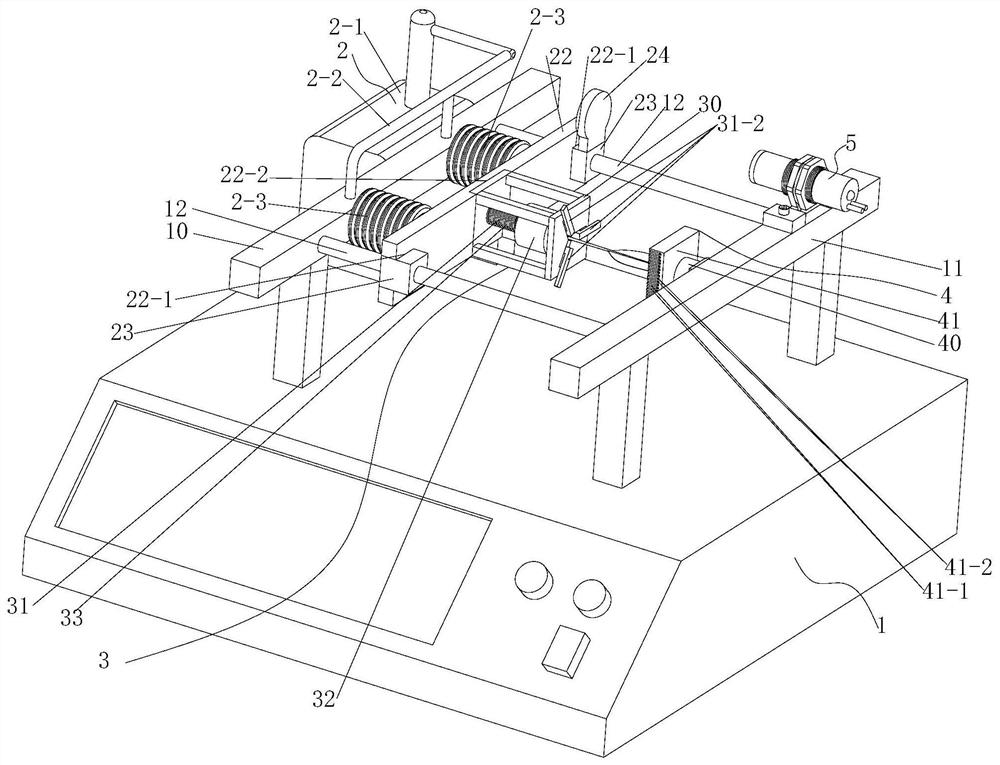

[0043] When the mobile supercharging device 2 adopts the air bag 2-3, the air pump 2-1 supplies air to the air bag 2-3 through the air delivery pipe 2-2, and changes the moving distance of the moving plate 22 by controlling the amount of intake air. The range finder 5 collects the distance value that the moving plate 22 moves forward with the tail clamping mechanism 3 clamping the feather, and the pressure value after the feather stem is gradually bent by the pressure sensor 41-2, and collects multiple groups Data, and then use the moving distance as the X axis and the pressure as the Y value to draw a line graph. The closer the line graph is, the more similar the shape and quality of the feathers are, so as to select 16 feathers on a ball in shape and quality All almost the same raw films provide data reference.

Embodiment 3

[0045] The end of the tailstock 30 is provided with three rectangular grooves 30-1, and the three rectangular grooves 30-1 are evenly distributed at an angle of 120 degrees in the circumferential direction, and the clamping sleeve 31 is provided with three chucks 31- 1, and the three chucks 31-1 are uniformly distributed at an angle of 120 degrees in the circumferential direction, the chucks 31-1 are hinged with the ends of the clamping sleeve 31, and the ends of the chucks 31-1 are provided with opening and closing The limit rod 31-2, and the clamp of the opening and closing limit rod 31-2 is in the rectangular groove 30-1, which ensures that the clamping action of the three chucks 31-1 is performed when the compression spring 33 exerts force on the tapered sleeve 32. Consistency and clamping stability; the threaded hole in the center of the adjusting screw 34 and the clamping sleeve 31 is connected by a screw pair, which can adjust the insertion depth of the tail of the hair ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com