A spot welding machine with automatic blanking structure

A spot welding machine and blanking technology, which is applied to welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of inconvenient blanking, affecting work efficiency, and inconvenient loading and clamping, so as to improve processing efficiency and improve work efficiency. Good efficiency and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

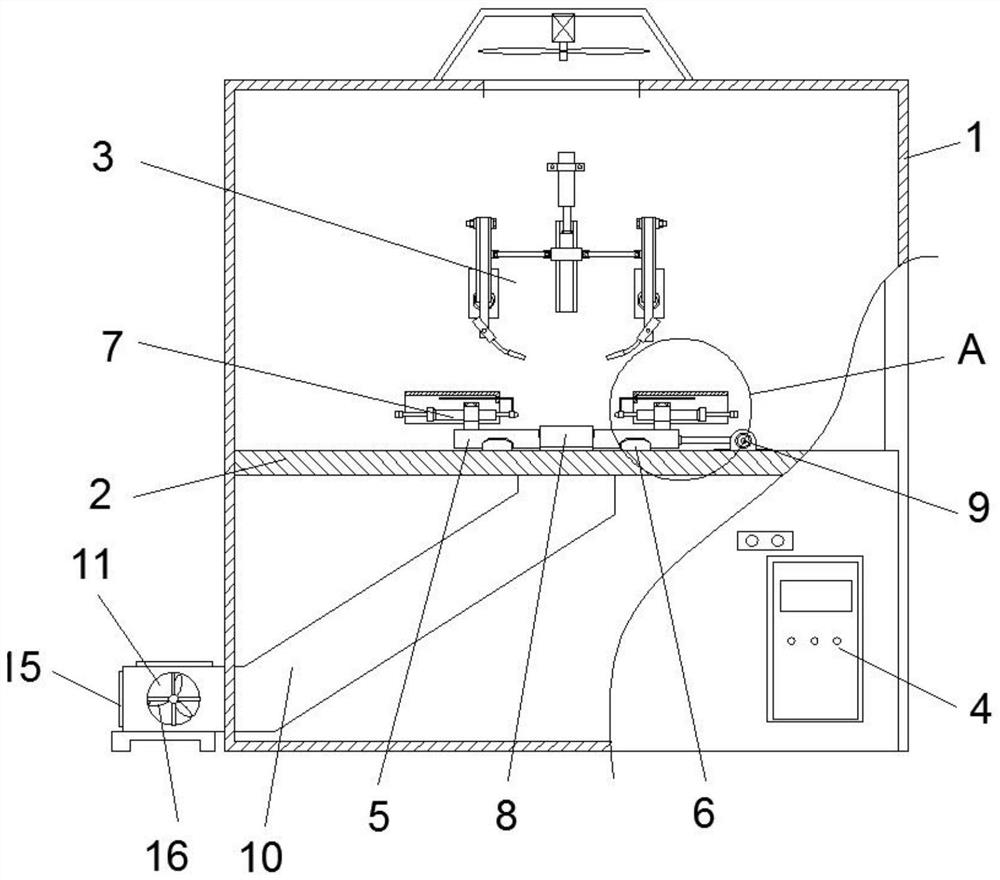

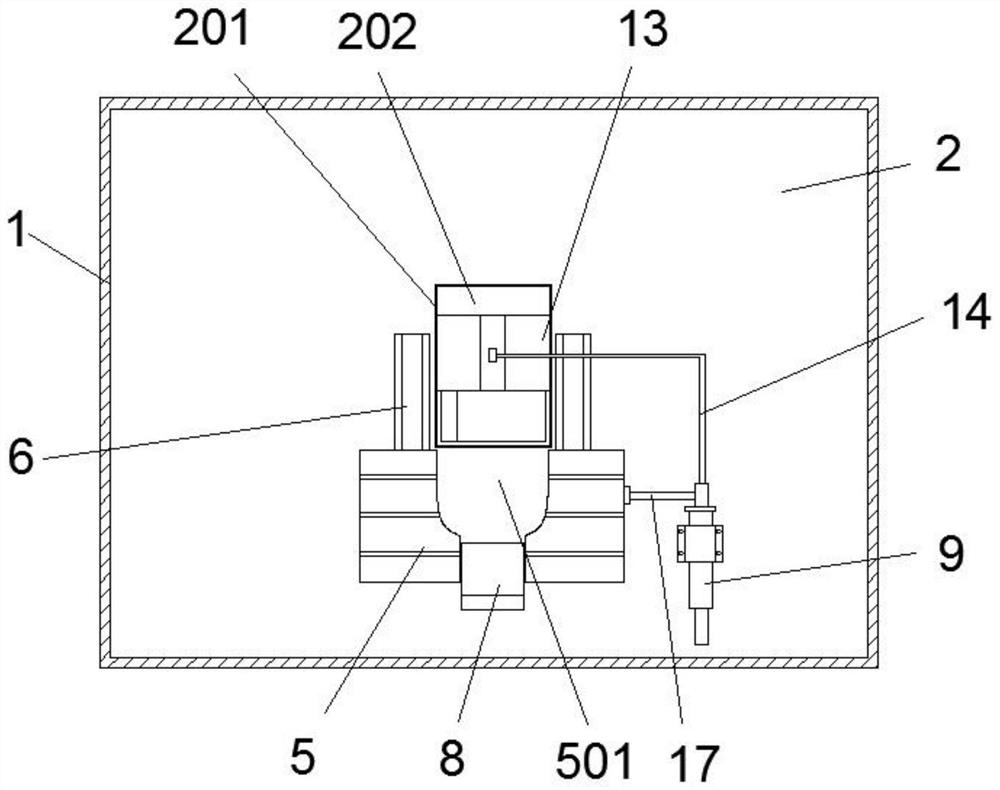

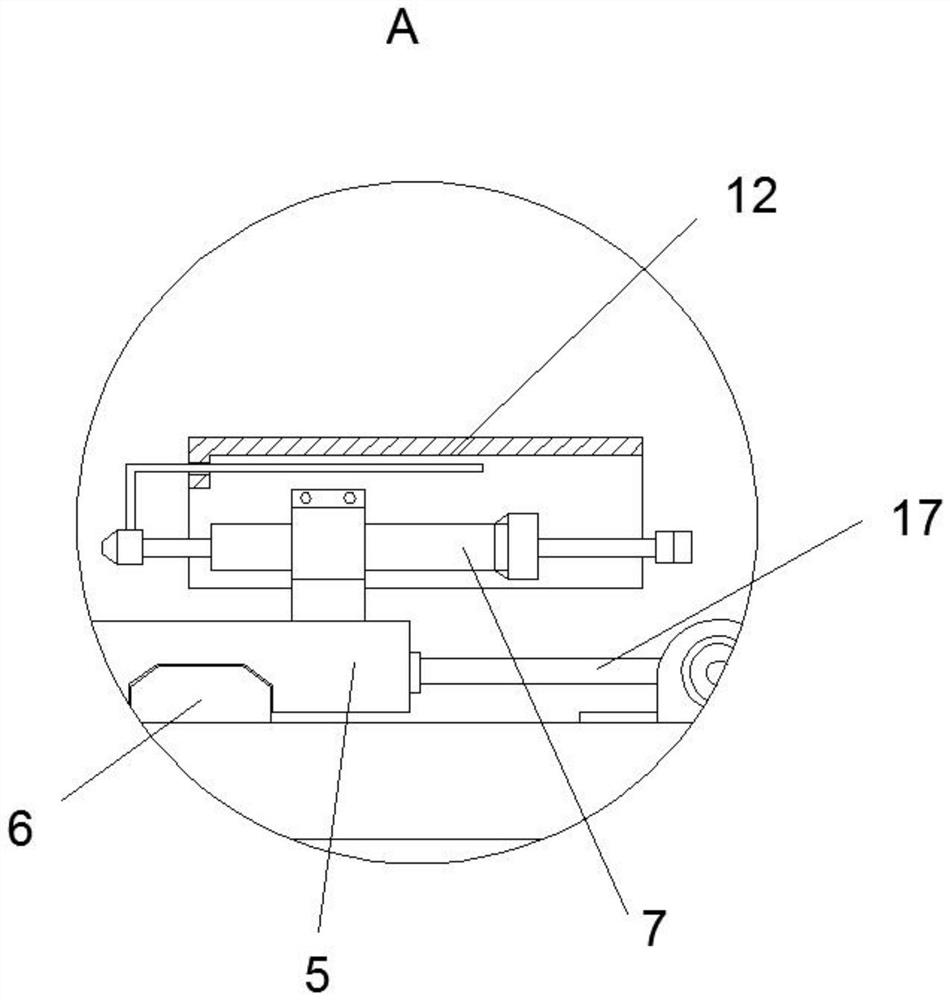

[0026] A kind of spot welding machine with automatic blanking structure of the present embodiment, refer to Figure 1-3 : including a protective case 1, a mounting plate 2, an automatic welding machine 3 and an electrical cabinet 4, and is characterized in that it also includes an automatic clamping structure and an automatic blanking structure, and the automatic clamping structure includes a slide table 5 and a slide rail 6, the slide rail 6 is symmetrically fixed on the mounting plate 2, and the slide table 5 is slidably clamped on the slide rail 6. The clamping cylinder 7 is symmetrically installed on the front side of the top of the slide table 5, and a U-shaped through groove 501 is opened on the top of the slide table 5. An L-shaped placement plate 8 is fixed between the rails 6, and the front end of the slide table 5 is clamped in the L-shaped placement plate 8; the automatic blanking structure includes a feeding cylinder 9, a slideway 10 and a cooling chamber 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com