Deposition method of interlayer film

A deposition method and interlayer film technology, applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve pollution, cross-contamination and other problems, to avoid cross-contamination, improve utilization rate, and improve shipment volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

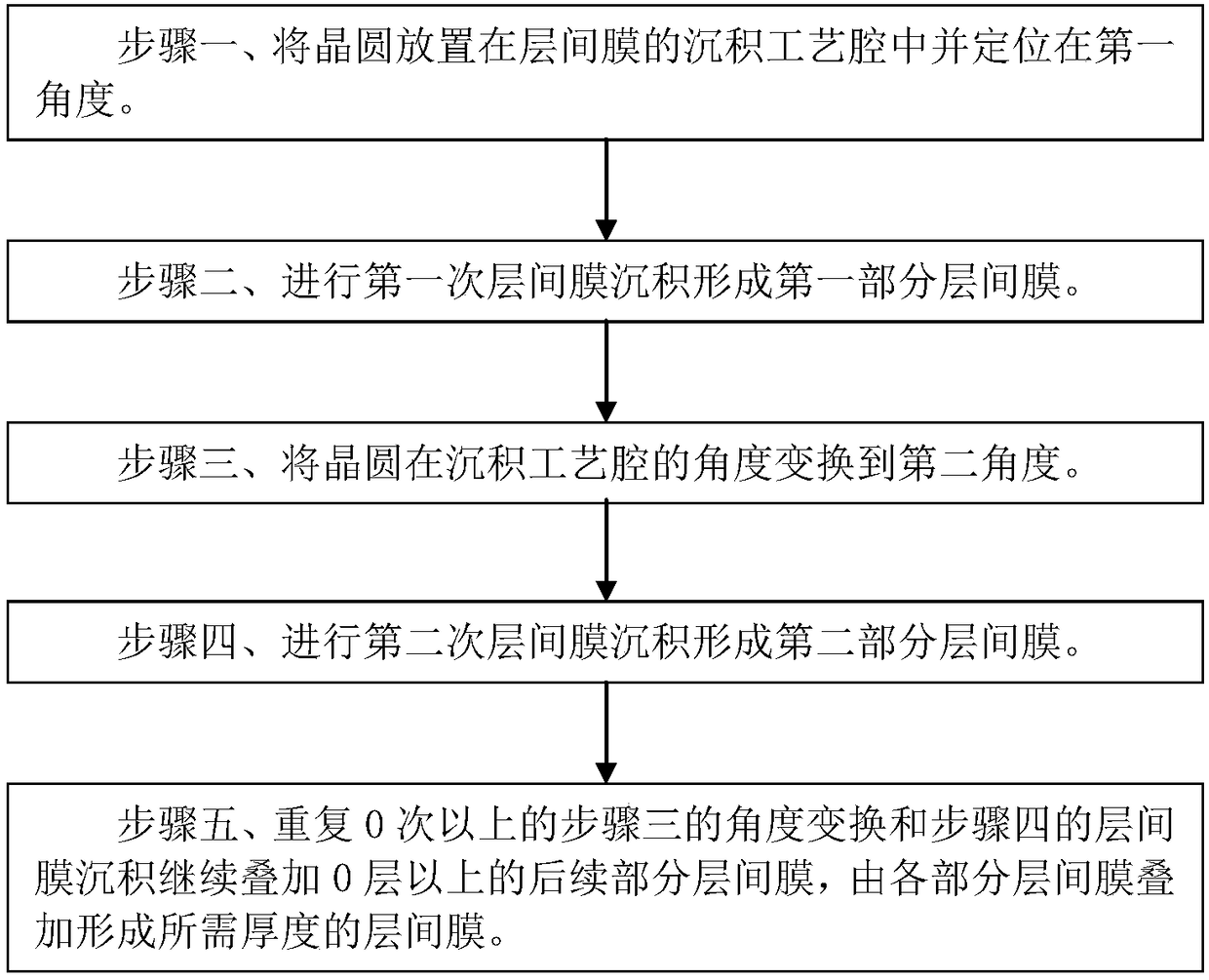

[0040] Such as figure 1 As shown, it is a flowchart of the deposition method of the interlayer film in the embodiment of the present invention. The deposition method of the interlayer film in the embodiment of the present invention includes the following steps:

[0041] Step 1, providing a wafer composed of a semiconductor substrate, placing the wafer in a chamber for depositing an interlayer film and positioning it at a first angle.

[0042] The semiconductor substrate is a silicon substrate. The material of the interlayer film is silicon oxide.

[0043] Notches for angular positioning are provided on the wafer.

[0044] In the embodiment of the present invention, the angular positioning and rotation of the wafer is realized in the deposition process chamber, and the position of the notch of the wafer is detected by an angle sensor arranged in the deposition process chamber to realize the positioning of the wafer. The angle positioning of the wafer, the wafer carrying tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com