Tobacco bale in-place supplementing alarm device

A technology of alarm device and cigarette pack, applied in the field of cigarette pack position alarm device and cigarette pack position alarm device of GDX2 packaging machine, which can solve the problem that equipment operation cost, efficiency and quality are greatly affected, and equipment stability and reliability are affected. , turret deformation and damage and other problems, to achieve the effect of eliminating quality defects and equipment safety hazards, solving machine design defects, and improving the function of the original machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with specific embodiment and accompanying drawing, the application is further described:

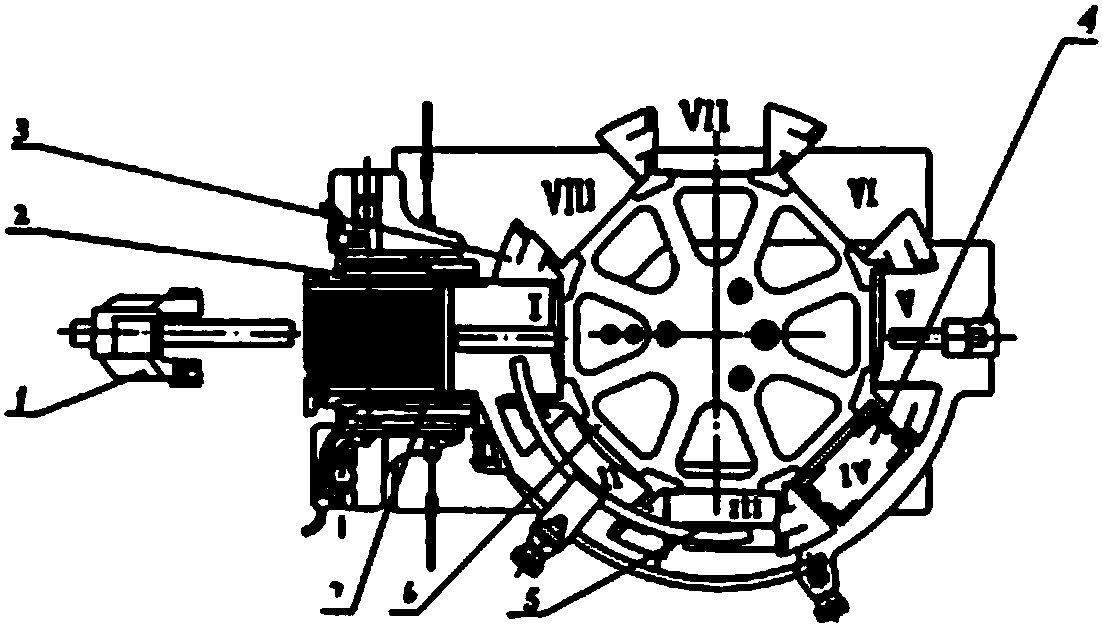

[0029] 1. Add a detection device for cigarette pack replenishment

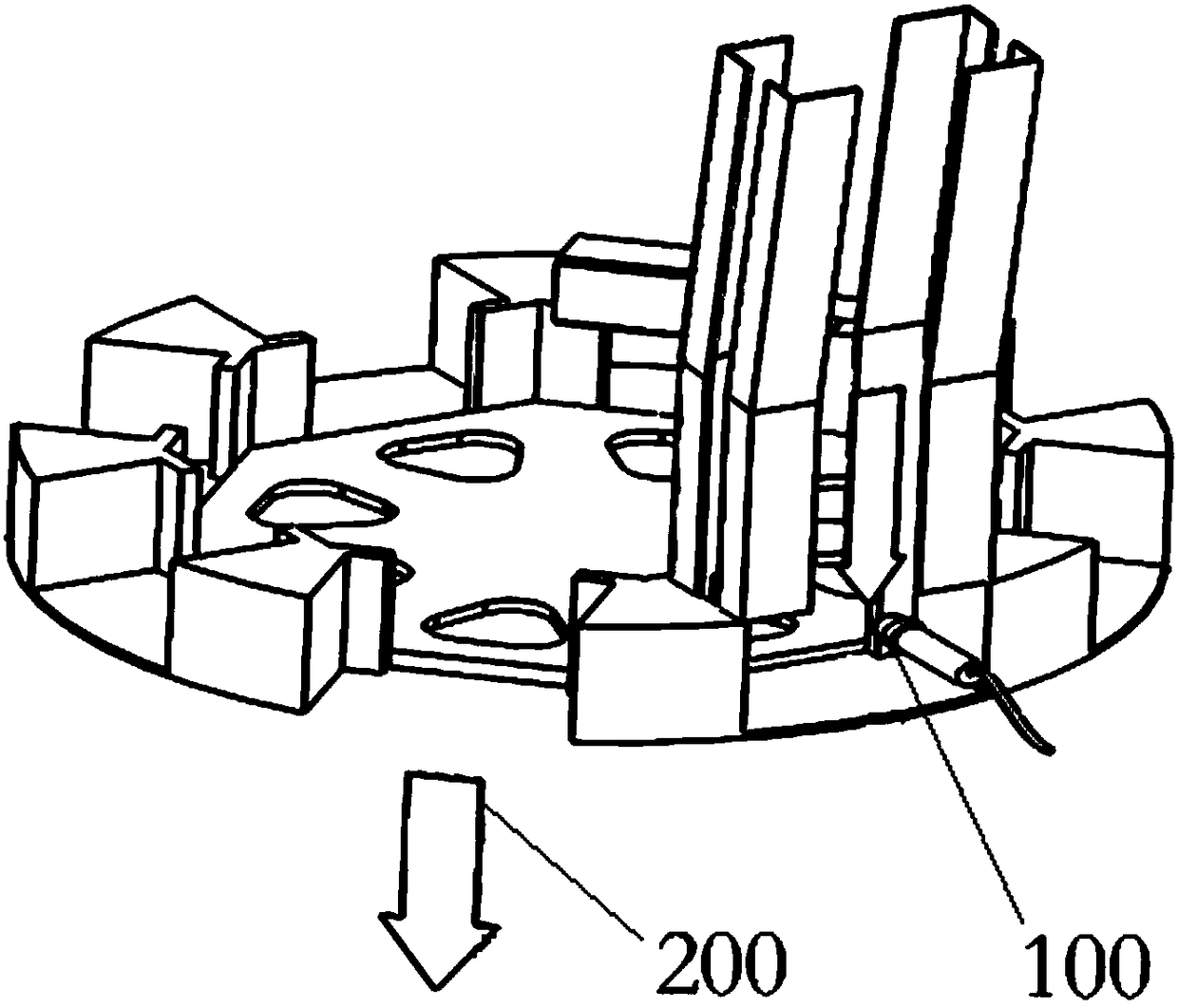

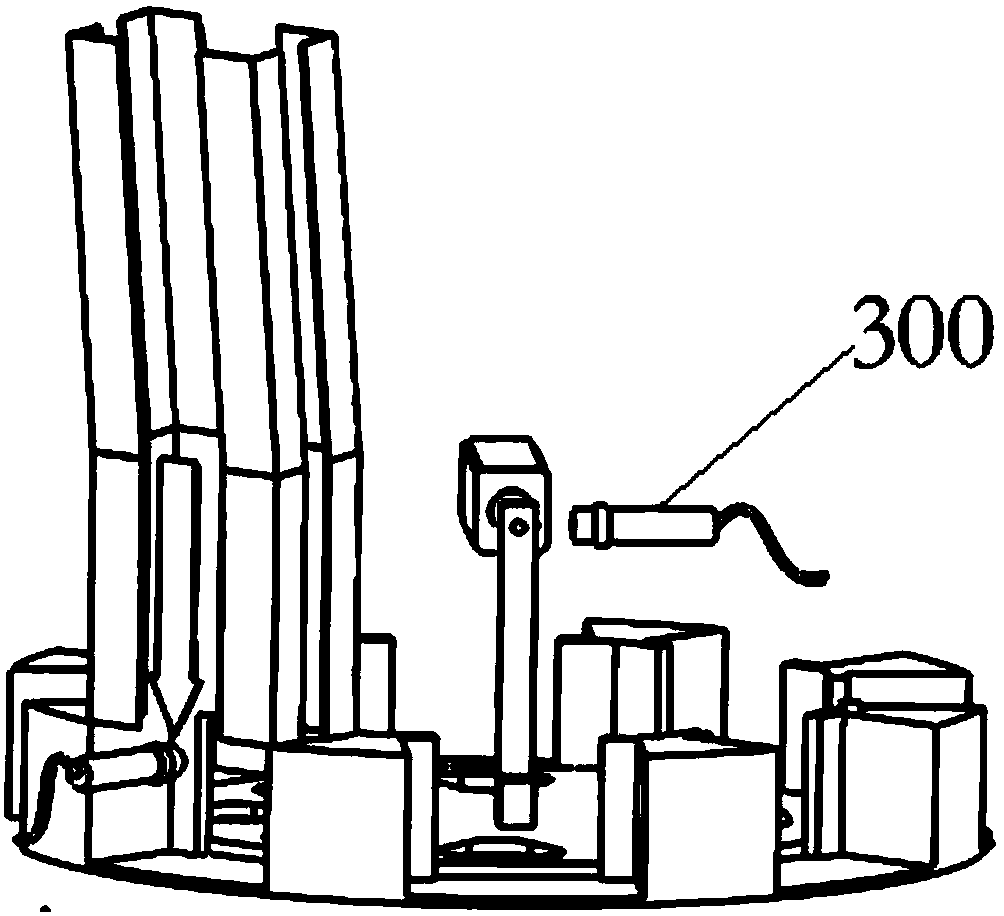

[0030] At the next station of the rejection port 200, that is, the smoke filling device ( figure 2 ) add a cigarette pack in-place detection device 100. Considering the small installation location and the change of cigarette pack auxiliary materials, an optical fiber is selected to detect the cigarette packs at the removed mouth, and an 8MM hole is opened at the outer wall of the turret to install the optical fiber. The edge is 10MM, and the left and right are centered. When it is necessary to replenish the cigarette pack, it will identify the position of the cigarette pack, and send the signal to the PLC for logical judgment, such as image 3 The installation position of the optical fiber is shown in a specific embodiment: fiber type: E32-DC200; amplifier type: FS2-60P, brand: Omron.

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com