Three-dimensional printing method based on DLP (digital light processing) projection photocuring and equipment

A technology of 3D printing and projection light, which is applied in metal processing equipment, 3D modeling, 3D object support structure, etc., can solve the problems of part forming speed increase, process cost increase, part fine feature distortion, etc., to ensure the forming dimensional accuracy and fineness, improve molding efficiency, and reduce data distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

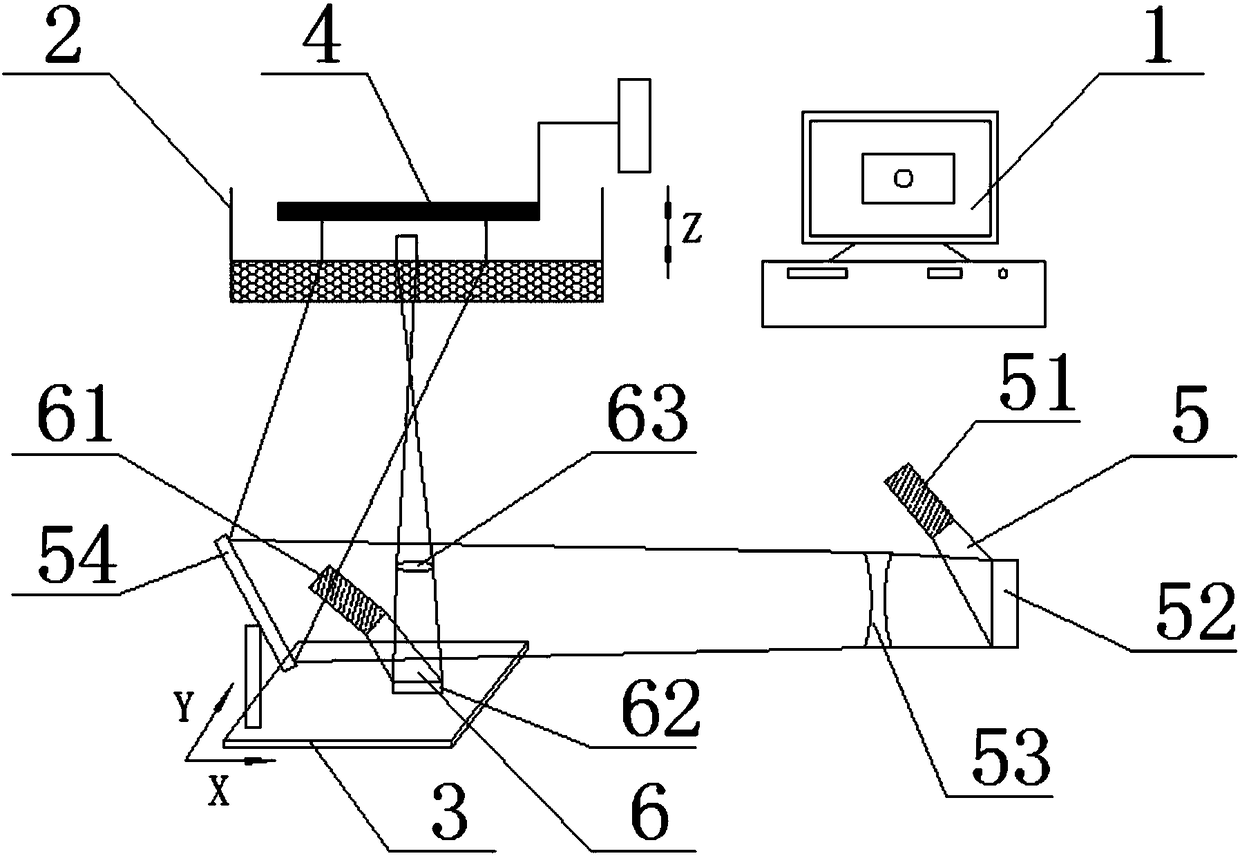

[0039] The core of the present invention is to provide a three-dimensional printing method and equipment based on DLP projection light curing. In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail in conjunction with specific examples below.

[0040] refer to figure 1 , which shows the implementation flow chart of the DLP-based projection photocuring three-dimensional printing method of the present invention. First, use modeling units such as Proe or Solidworks to build a 3D model of the pre-generated object, and avoid sharp corners or narrow gap structures during the modeling process. The above-mentioned three-dimensional model is simulated and layered by using the digital slicing unit, and the thickness value of each layer must be set according to the actual working capacity of the printing device to produce multiple Z-direction (ie, height direction) cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com