Rotary working platform type sound insulation room

A technology of rotating worktable and rotating work, applied in the direction of sound insulation, insulation layer, industrial buildings, etc., can solve the problems affecting the health of operators, troubles of operators, etc., and achieve good health, improve sound insulation performance, and reduce transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

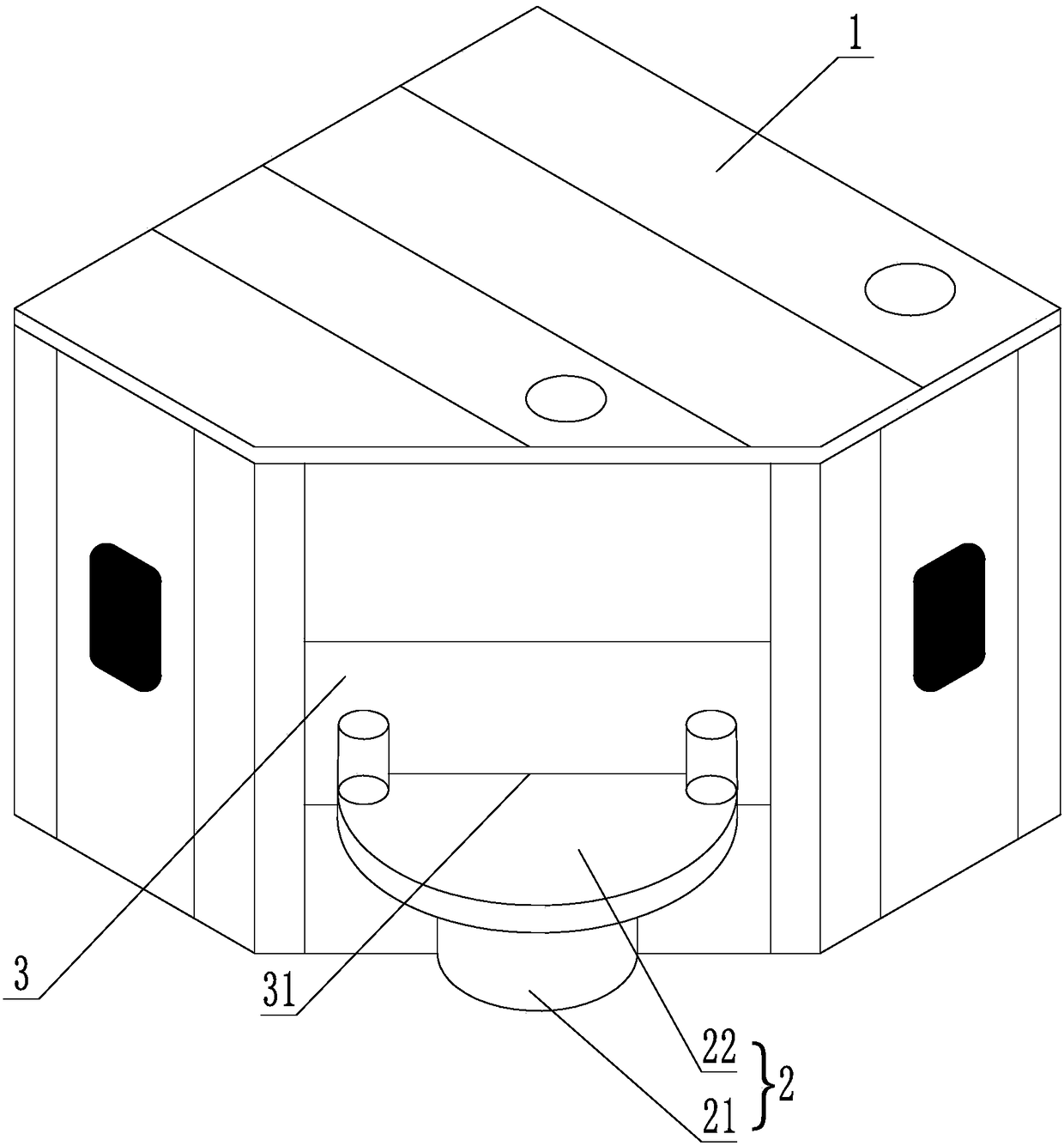

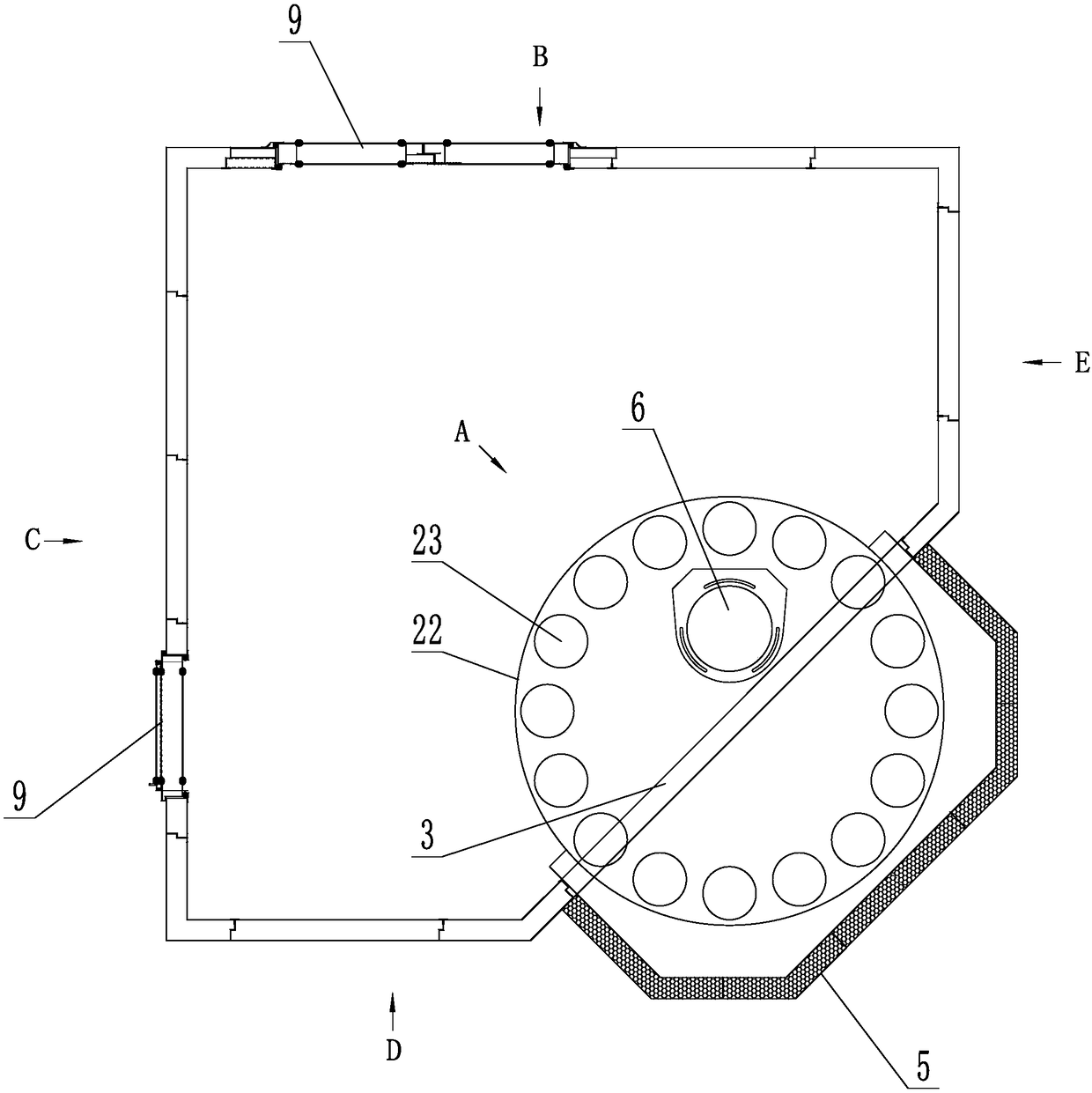

[0041] A rotary workbench type sound insulation room, as attached figure 1 As shown, the sound insulation room is mainly composed of two parts: the sound insulation room body 1 and the rotary worktable 2, in which the sound insulation room body 1 is connected vertically by four side panels in turn, and the other side panel is connected and sealed to form a pentagonal structure , the top of the five side panels is provided with a top cover to form a closed sound insulation room, each panel is filled with sound insulation materials, and processing equipment is installed in the sound insulation room body 1 .

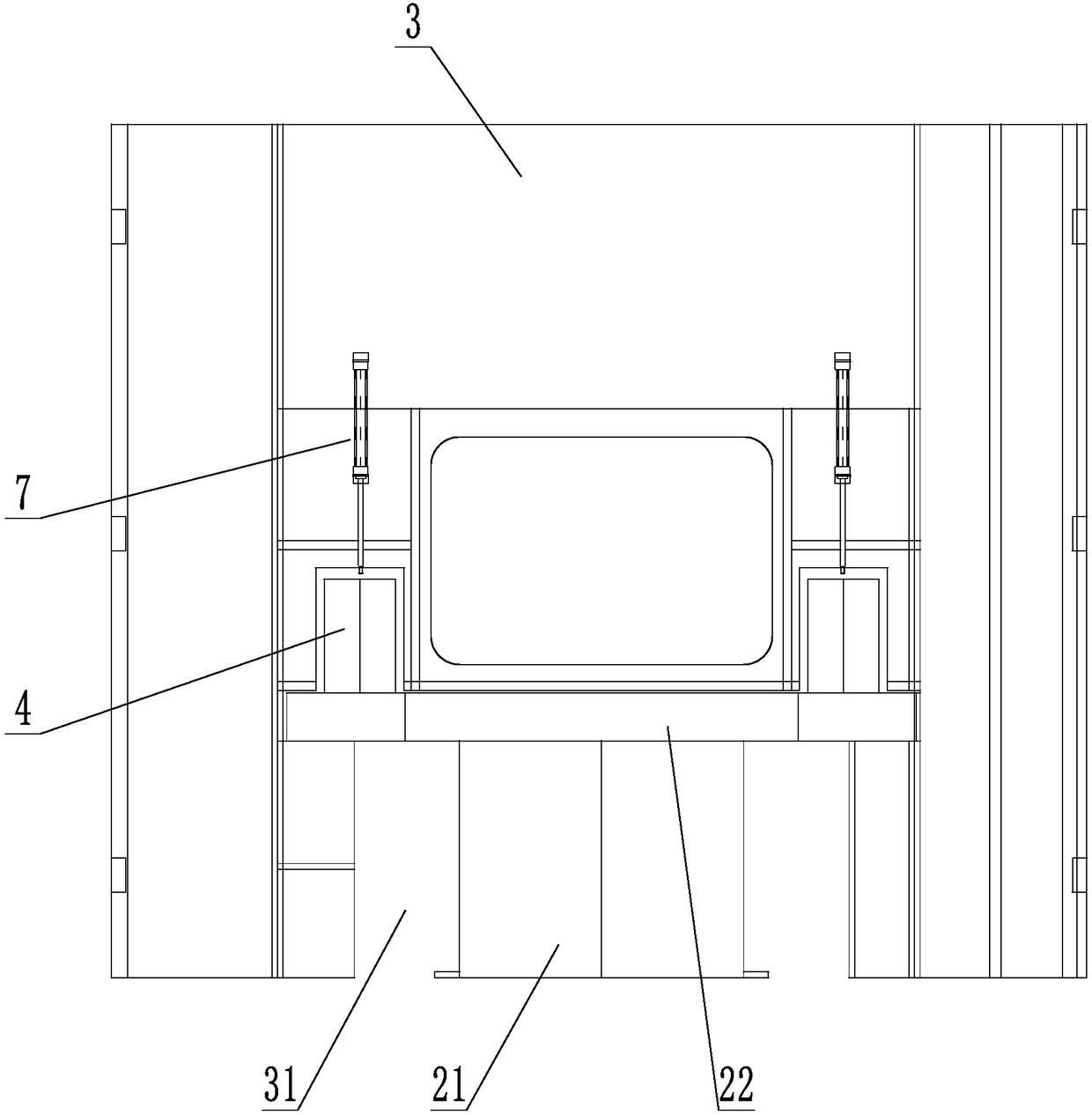

[0042] Wherein, the plate body connecting four vertical splicing side plates is a slotted wall body 3, and the lower end of the slotted wall body 3 is provided with a slot 31 connected to the ground, and a rotary table 2 is installed in the slot 31, and the rotary work The table 2 includes a cylindrical base 21 at the lower end and a disc-shaped turntable 22 rotatably conne...

Embodiment 2

[0050] as attached Figure 8 As shown, the dodge door 4 is opened or closed by rotating inside and outside. Specifically, the dodge door 4 is a rectangular plate-shaped structure, and its upper end is rotatably connected to the top of the groove 31 opposite to the workpiece position. When the work position 23 rotates with the turntable 22 , dodge door 4 opens to the direction that turntable 22 rotates, and after workpiece position 23 passes through, dodge door 4 falls back and closes.

[0051] During specific implementation, a pusher 24 that pushes the dodge door 4 to be opened is installed on each workpiece position 23 near the side of the center of circle of the turntable 22. In this embodiment, the pusher 24 is a U-shaped bar whose height is greater than the workpiece to be processed, so as to prevent movement. Door 4 scratches the workpiece. During use, the pusher 24 moves against the dodge door 24 along with the workpiece position 23, and the dodge door 4 is pushed back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com