A new composite material of chlorinated polyethylene rubber and its preparation method

A technology of chlorinated polyethylene and rubber composition is applied in the field of chlorinated polyethylene composite new material and its preparation, and can solve the problems of high cost, poor flame retardant performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

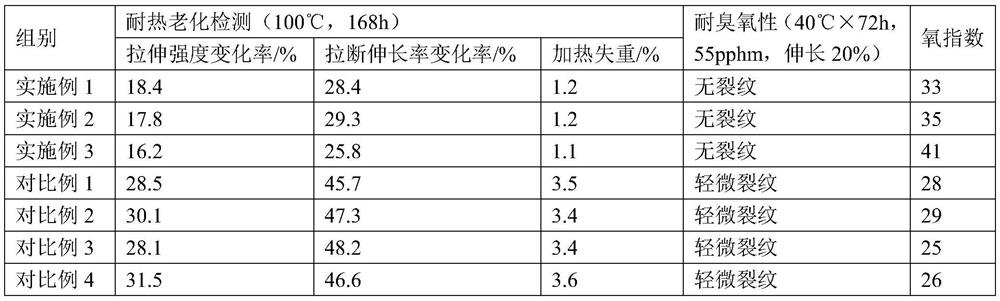

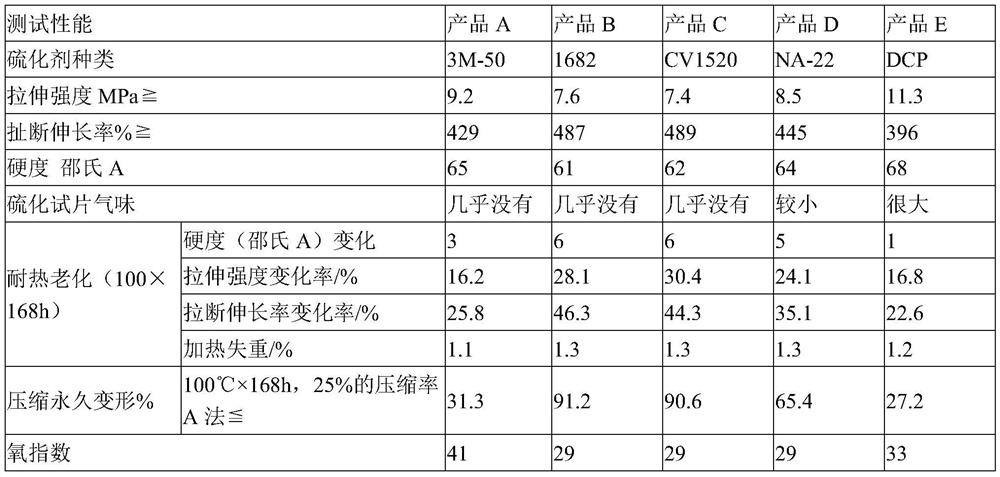

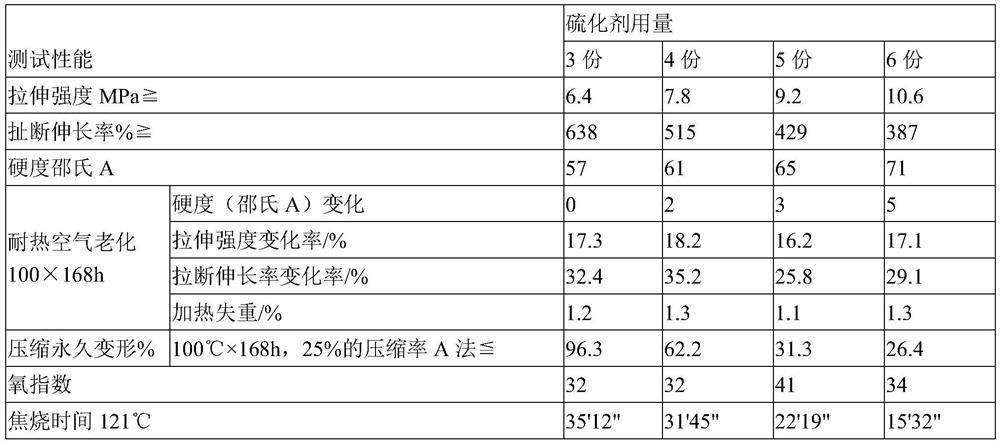

Examples

Embodiment 1

[0025] A new composite material of chlorinated polyethylene rubber, which consists of: 100kg of rubber type chlorinated polyethylene, 7kg of magnesium hydroxide, 35kg of semi-reinforced 774 carbon black, 60kg of 990 carbon black, 0.5kg of stearic acid, stearic acid Calcium 2kg, kaolin E2 15kg, dioctyl terephthalate 25kg, protective wax 0.5kg, antimony trioxide 4kg, thiadiazole vulcanizing agent ECHO S 8083M-504.5kg.

[0026] The preparation method of chlorinated polyethylene rubber sealing strip is:

[0027] (1) take chlorinated polyethylene rubber and various auxiliary agents according to the formula;

[0028] (2) Put the additives other than the vulcanizing agent and the weighed chlorinated polyethylene rubber into the internal mixer, and control the rubber mixing temperature ≦ 100°C by passing cooling water. After mixing the rubber for 3 minutes, add the vulcanizing agent and then Knead for about 1.5 minutes and discharge, make 4-5 triangular bags on the open mill, then th...

Embodiment 2

[0031] A new composite material of chlorinated polyethylene rubber, which consists of: 100kg of rubber type chlorinated polyethylene, 10kg of magnesium hydroxide, 40kg of semi-reinforced 774 carbon black, 70kg of 990 carbon black, 1kg of stearic acid, calcium stearate 3kg, kaolin E2 20kg, dioctyl terephthalate 32kg, protective wax 1kg, antimony trioxide 6kg, thiadiazole vulcanizing agent ECHO S 808 3M-505.5kg.

[0032] The preparation method of chlorinated polyethylene rubber sealing strip is the same as embodiment 1.

Embodiment 3

[0034] A new composite material of chlorinated polyethylene rubber, which consists of: 100kg of rubber-type chlorinated polyethylene, 8.5kg of magnesium hydroxide, 37.5kg of semi-reinforced 774 carbon black, 65kg of 990 carbon black, 0.75kg of stearic acid, hard Calcium fatty acid 2.5kg, kaolin E217.5kg, dioctyl terephthalate 28.5kg, protective wax 0.75kg, antimony trioxide 5kg, thiadiazole vulcanizing agent ECHOS808 3M-50 5kg.

[0035] The preparation method of chlorinated polyethylene rubber sealing strip is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com