Single-component alkali-activated fly ash cement

A technology of fly ash cement and alkali excitation, applied in the field of cement materials, can solve the problems of environmental pollution and high energy consumption, and achieve the effects of simple use method, simple process and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

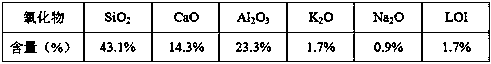

[0015] A kind of single-component alkali activated fly ash cement, its preparation method comprises the steps:

[0016] (1) Recycle and store fly ash to avoid mixing or polluting fly ash with other sundries;

[0017] (2) Mix fly ash, solid sodium hydroxide, solid magnesium oxide, and solid calcium oxide in proportion, and ball mill for 2 hours to get the finished product.

[0018] The raw materials used are calculated by weight percentage: fly ash 70%-80%, solid sodium hydroxide 12%-16%, solid magnesium oxide 3%-7%, solid calcium oxide 5%-7%, the weight percentage of each raw material The sum is 100%.

[0019] The single-component alkali-activated fly ash cement and its weight of 28%-38% of water are directly mixed to form cement paste, so that the cement paste has better fluidity, and then poured, and the setting time of the cement paste is immediately adjusted. Test: After vibrating and compacting, maintain at room temperature for 3 days to obtain a cement slurry test bloc...

Embodiment 1

[0025] (1) Recycle and store fly ash to avoid mixing or polluting fly ash with other sundries;

[0026] (2) Mix 75% of fly ash, 14% of solid sodium hydroxide, 5% of solid magnesium oxide, and 6% of solid calcium oxide by weight percentage, and then ball mill for 2 hours to obtain a single-component alkali-activated fly ash cement;

[0027] Stir and mix the obtained single-component alkali-activated fly ash cement with 35% of its weight of water for 2 minutes to form a cement slurry, and then cast it into a test block of 40mm×40mm×160mm. The measured initial setting time is 38 minutes, and the final setting time After vibrating and compacting, it was cured at room temperature for 3 days to obtain a cement slurry test block. The flexural strength was 2.8MPa and the compressive strength was 25MPa, which can meet the actual engineering needs.

Embodiment 2

[0029] (1) Recycle and store fly ash to avoid mixing or polluting fly ash with other sundries;

[0030] (2) Mix 70% of fly ash, 16% of solid sodium hydroxide, 7% of solid magnesium oxide and 7% of solid calcium oxide by weight percentage and then ball mill for 2 hours to prepare single-component alkali-activated fly ash cement.

[0031] Stir and mix the obtained single-component alkali-activated fly ash cement with 37% of its weight of water for 2 minutes to form a cement slurry, and then cast it into a test block of 40mm×40mm×160mm. The measured initial setting time is 36 minutes, and the final setting time After vibrating and compacting, it was cured at room temperature for 3 days to obtain a cement slurry test block. The flexural strength was 2.9MPa and the compressive strength was 27MPa, which can meet the actual engineering needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com