Novel electric control fuel oil system

A technology of fuel system and electronic control, which is applied in the direction of layout, container and packaging combined with the fuel supply of internal combustion engines, which can solve the problems of insufficient fueling smoothness, low resolution, inaccurate volume control and liquid level display, etc., and achieve overall The effect of compact structure design, improved performance and quality, and improved smoothness of refueling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

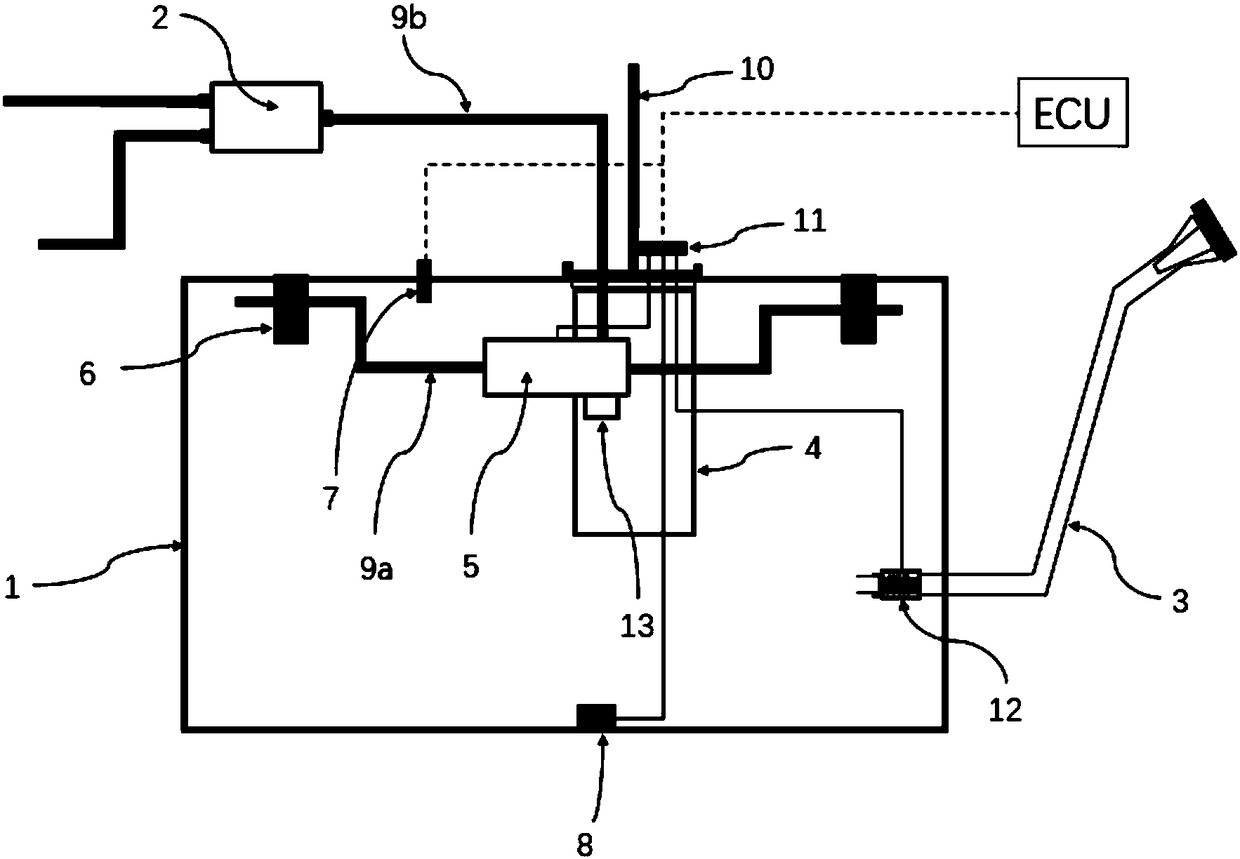

[0031] Embodiment 1: see figure 1, Figure 2, a new electronically controlled fuel system, the fuel system includes a fuel tank body 1, a carbon tank 2, a fuel injection pipe 3, a fuel pump 4, an electronically controlled exhaust valve 5, a vent 6, an air pressure sensor 7, and a liquid level sensor 8. Ventilation pipeline 9, oil supply / return pipeline 10, control unit 11, and electronically controlled check valve 12. For the four modules of fuel storage, fuel delivery, steam management, and measurement control of the fuel system, this solution is mainly for fuel storage. , steam management and performance of measurement control are improved, the carbon canister 2 and the vent 6 inside the fuel tank communicate with the electronically controlled exhaust valve 5 through the vent pipeline 9, and the electronically controlled exhaust valve 5 is arranged in the fuel tank body 1 , can be arranged freely according to the specific shape and space of the fuel tank; the pressure liquid ...

Embodiment 2

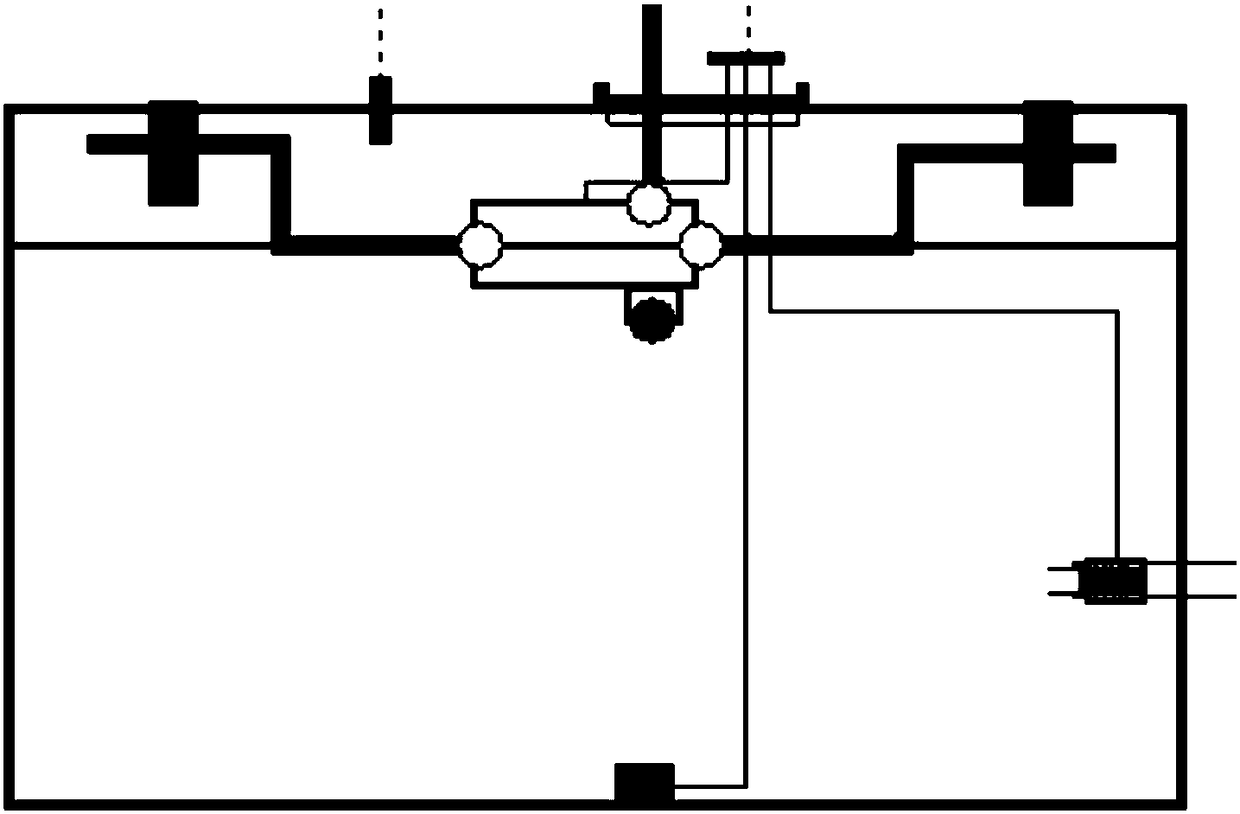

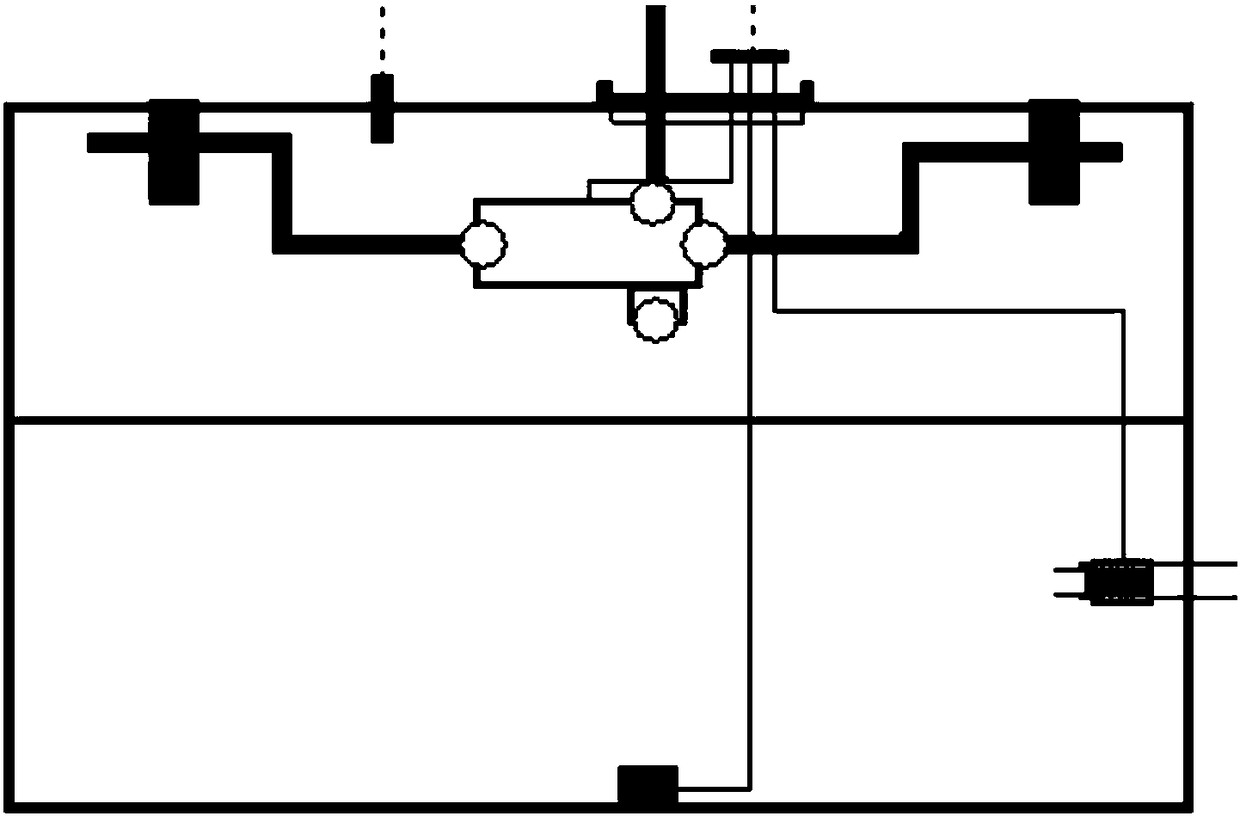

[0032] Example 2: see figure 1 , as an improvement of the present invention, the electronically controlled exhaust valve 5 adopts a combined structure of an electromagnetic valve and a mechanical valve, so that it has two valve flow directions of exhaust and liquid discharge, and the electromagnetic valve module and the mechanical valve The valve modules all have a two-stage opening mode. The electromagnetic valve is in the mode of large flow and small flow to control the ventilation volume; the closed state of the mechanical valve module is to close the valve and the drain port of the fuel tank and the interface between the valve and the air port leading to the carbon tank at the same time, and the first-level open state is closed The valve and the drain port of the fuel tank prevent fuel from entering the carbon tank through the valve, and open the interface between the valve and the vent leading to the carbon tank. The vent interface, such as Figure 2a , 2b shown. This...

Embodiment 3

[0033] Embodiment 3: As an improvement of the present invention, the liquid level sensor 8 adopts a piezoresistive pressure sensor as a measuring device, and uses a strain gauge (DMS) method for pressure measurement. Silicon wafer is selected as DMS, and metal (steel) is used as thin film. The signal generated by the pressure sensor is sent to the electronic control unit after temperature compensation. Combined with the internal air pressure signal measured by the air pressure sensor, the accurate fuel level information is obtained through algorithm analysis. . Different types of fuel tanks only need to determine the installation position of the sensor, and use the algorithm to calibrate the liquid level, instead of redesigning the valve according to the fuel tank structure and closing height like the traditional fuel system. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com