Efficient eddy-current heating oil-transporting carbon precipitation-preventing mold temperature controller

A technology of eddy current heating and mold temperature machine, which is applied in the field of high-efficiency eddy current heating oil-carrying anti-deposition carbon mold temperature machine, can solve the problems of affecting the heating efficiency of the mold temperature machine, the maintenance cost, the heating efficiency of the heating rod, and the long downtime. Achieve the effect of low disassembly cost, reliable structure and high eddy current heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

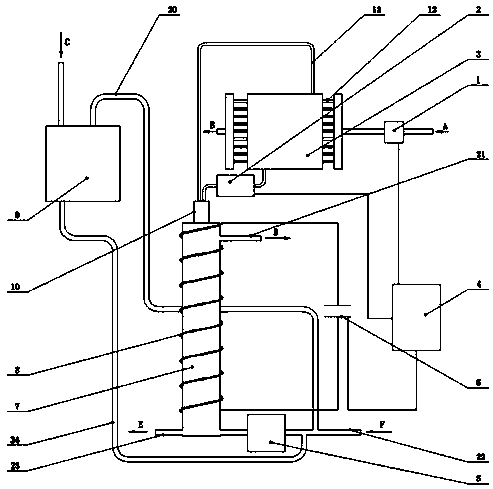

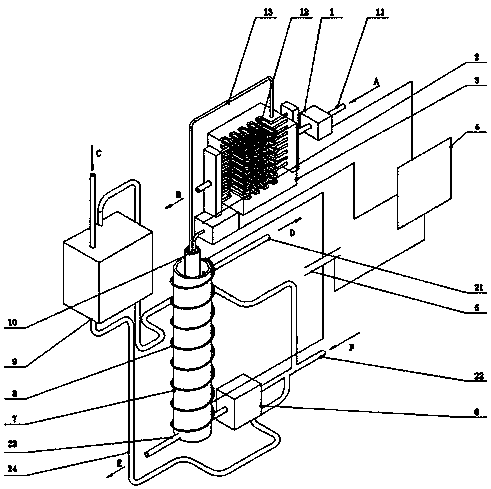

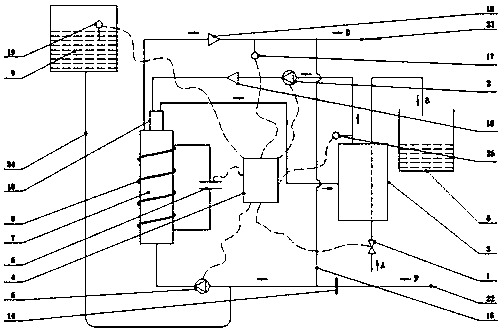

[0033] Referring to the accompanying drawings, a high-efficiency eddy current heating oil-carrying anti-carbon precipitation mold temperature machine includes a solenoid valve 1, a cold oil pump 2, a cooling heat transfer oil storage tank 3, an intelligent PLC controller 4, a high-frequency power supply 5, and an oil pump 6. Heating oil reservoir 7, eddy current power supply coil 8, heating oil storage tank 9, cooling pipe 10, water pipe 11, cooling pipe 12, oil return pipe 13, heat transfer oil filter 14, oil inlet and outlet connecting pipe 15, cooling heat transfer oil check valve 16. Heat transfer oil temperature sensor 17, heating heat transfer oil check valve 18, heat transfer oil cursor 19, heat transfer oil exhaust pipe 20, heat transfer oil mold oil delivery pipe 21, heat transfer oil mold return pipe 22, heat transfer oil discharge pipe 23, heat transfer oil Connecting pipe 24, cooling heat transfer oil temperature sensor 25, solenoid valve 1 is connected to water pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com