Welding robot

A welding robot and welder technology, used in welding equipment, manipulators, non-electric welding equipment, etc., to achieve the effects of controllable welding quality, low cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the drawings:

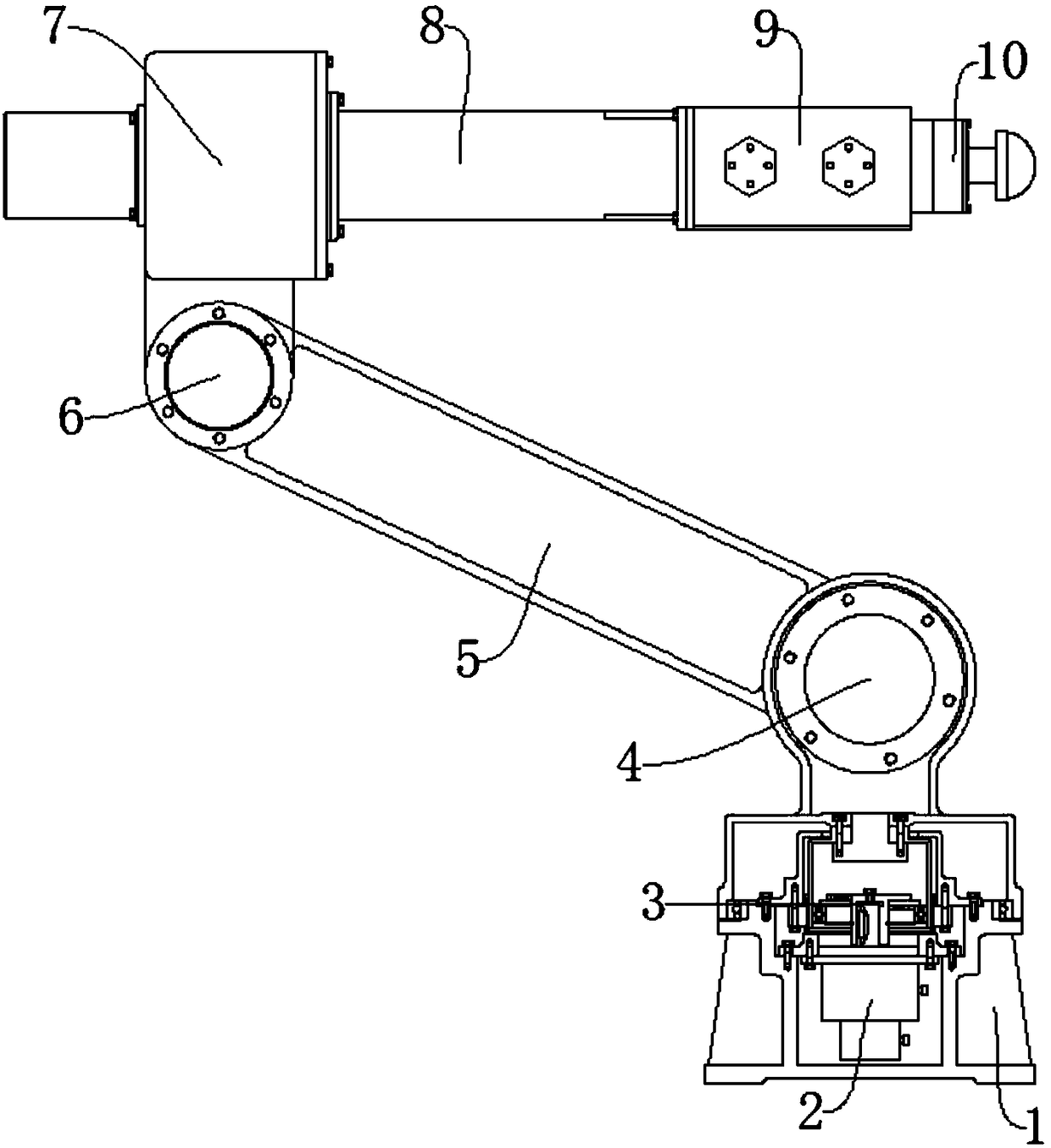

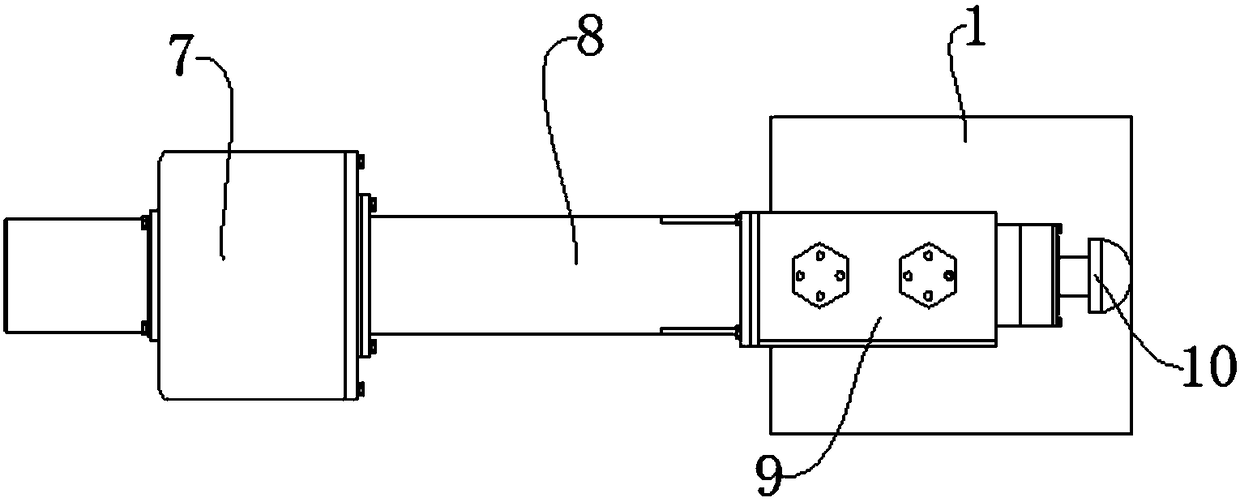

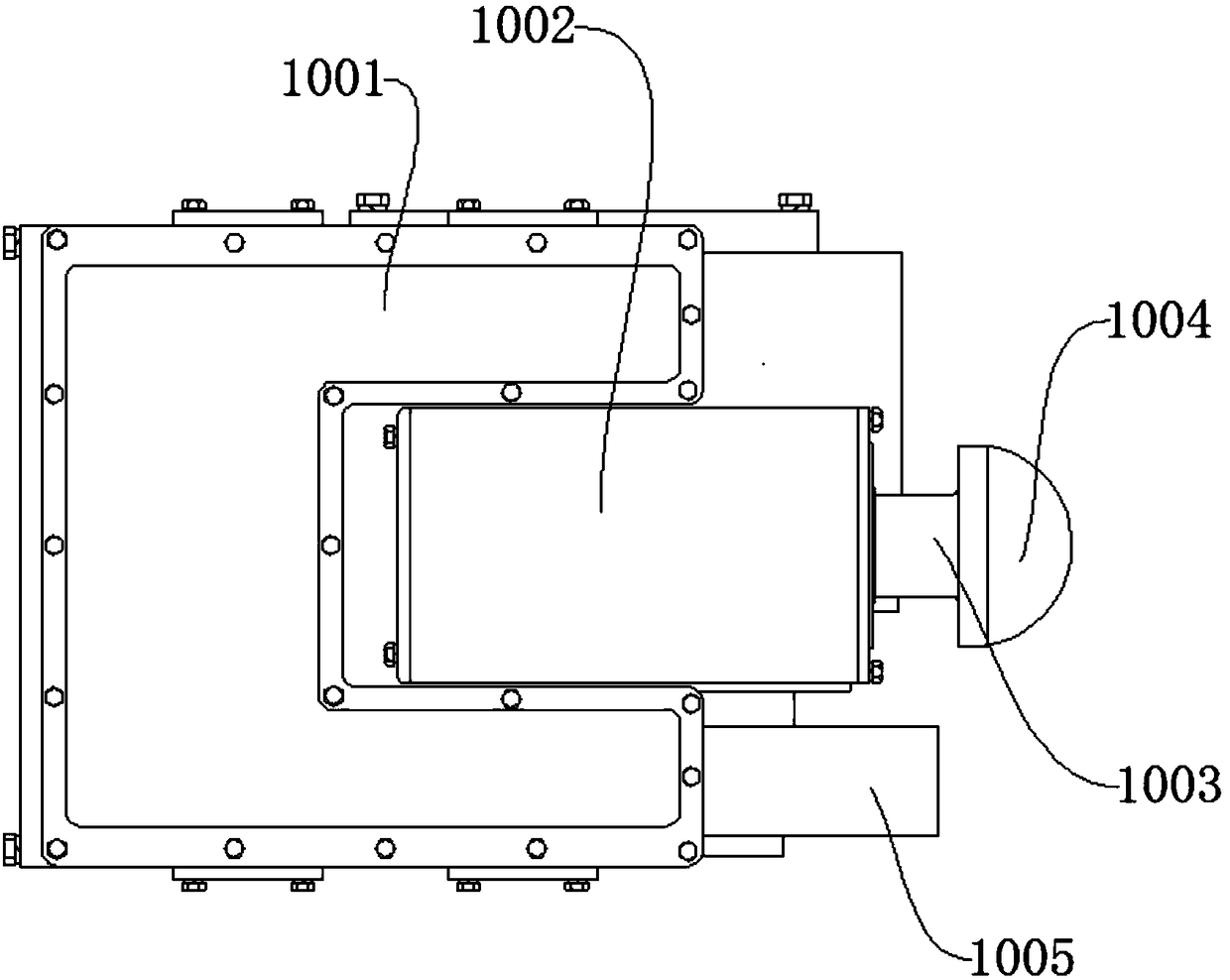

[0020] Such as Figure 1-3 As shown, a welding robot includes a base 1, a second motor 7 and a friction welder 10. The base 1 is provided with a first motor 2, and the first motor 2 is connected to a bottom shaft 4 through a transmission box 3. The bottom shaft 4 is connected to the top shaft 6 through the big arm 5, the top shaft 6 is arranged under the second motor 7, the second motor 7 is connected to the automatic controller 9 through the forearm 8, and the automatic controller 9 is connected to the friction welding machine 10 , The friction welding machine 10 is composed of a clamping sleeve 1001, a friction welding machine 1002, a snap-on connecting bolt 1003, a friction head 1004, and a positioner 1005. The friction welding machine 1002 is set inside the clamping sleeve 1001, and the friction welding machine 1002 and friction The head 1004 is connected by a snap-type connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com