Painted-face automatic drying system

A drying system and automatic technology, applied in the field of automation, can solve the problems of reduced production efficiency, long time consumption, poor use effect, etc., to achieve the effect of improving the degree of automation, avoiding manual work, and improving the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

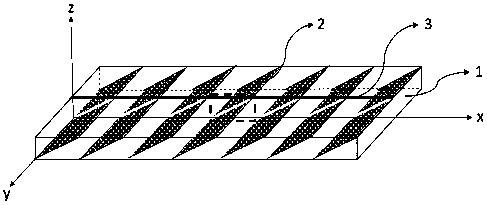

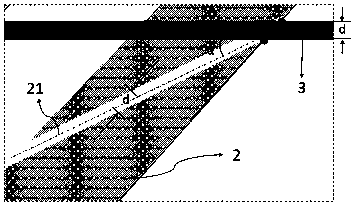

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

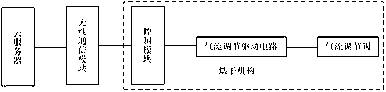

[0027] figure 1 It is a functional block diagram of the paint surface automatic drying system of the present invention.

[0028] like figure 1 As shown, the present embodiment 1 provides an automatic paint drying system, including: a cloud server and a drying mechanism, and a wireless communication module for information transmission between the cloud server and the drying mechanism; the cloud server It is suitable for storing the painted surface information of the workpiece and the corresponding drying parameters, and sending drying instruction information to the drying mechanism through the wireless communication module, so as to control the drying mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com