Preparation method of high-adsorptivity metal organic framework material

A metal-organic framework and high-adsorption technology, which is applied in the field of adsorption materials, can solve the problems of poor adsorption performance and achieve the effects of improving adsorption efficiency, reducing specific surface area, and reducing pore volume and pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

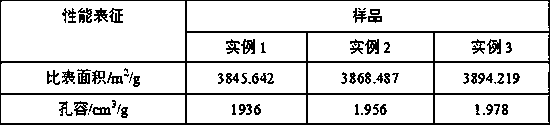

Examples

example 1

[0018] In terms of parts by weight, weigh 45-50 parts of deionized water, 10-15 parts of chromium nitrate, and 1-2 parts of terephthalic acid, stir and mix them and place them in a three-necked flask, and stir and mix at 45-50°C And dropwise add 5% hydrofluoric acid until the pH reaches 5.0. After the dropwise addition is completed, stir and mix to obtain a mixed solution and put it in a reaction kettle. After reacting at 200-250°C for 6-8 hours, let it stand and cool to room temperature and placed at 1500-2000r / min to centrifuge for 10-15min, collect the lower precipitate and wash it with acetone for 3-5 times, vacuum freeze-dry and grind to pulverize, and pass through a 100-mesh sieve to obtain sieved particles; Weigh 45 to 50 parts of absolute ethanol, 10 to 15 parts of N-methylimidazole, and 6 to 8 parts of chloroethylpiperidine hydrochloride and place them in a three-necked flask, ventilate nitrogen to remove the air, and control the rate of nitrogen introduction to 45 ~5...

example 2

[0020] In terms of parts by weight, weigh 45-50 parts of deionized water, 10-15 parts of chromium nitrate, and 1-2 parts of terephthalic acid, stir and mix them and place them in a three-necked flask, and stir and mix at 45-50°C And dropwise add 5% hydrofluoric acid until the pH reaches 5.0. After the dropwise addition is completed, stir and mix to obtain a mixed solution and put it in a reaction kettle. After reacting at 200-250°C for 6-8 hours, let it stand and cool to room temperature and placed at 1500-2000r / min to centrifuge for 10-15min, collect the lower precipitate and wash it with acetone for 3-5 times, vacuum freeze-dry and grind to pulverize, and pass through a 100-mesh sieve to obtain sieved particles; Weigh 45 to 50 parts of absolute ethanol, 10 to 15 parts of N-methylimidazole, and 6 to 8 parts of chloroethylpiperidine hydrochloride and place them in a three-necked flask, ventilate nitrogen to remove the air, and control the rate of nitrogen introduction to 45 ~5...

example 3

[0022] In terms of parts by weight, weigh 45-50 parts of deionized water, 10-15 parts of chromium nitrate, and 1-2 parts of terephthalic acid, stir and mix them and place them in a three-necked flask, and stir and mix at 45-50°C And dropwise add 5% hydrofluoric acid until the pH reaches 5.0. After the dropwise addition is completed, stir and mix to obtain a mixed solution and put it in a reaction kettle. After reacting at 200-250°C for 6-8 hours, let it stand and cool to room temperature and placed at 1500-2000r / min to centrifuge for 10-15min, collect the lower precipitate and wash it with acetone for 3-5 times, vacuum freeze-dry and grind to pulverize, and pass through a 100-mesh sieve to obtain sieved particles; Weigh 45 to 50 parts of absolute ethanol, 10 to 15 parts of N-methylimidazole, and 6 to 8 parts of chloroethylpiperidine hydrochloride and place them in a three-necked flask, ventilate nitrogen to remove the air, and control the rate of nitrogen introduction to 45 ~5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com