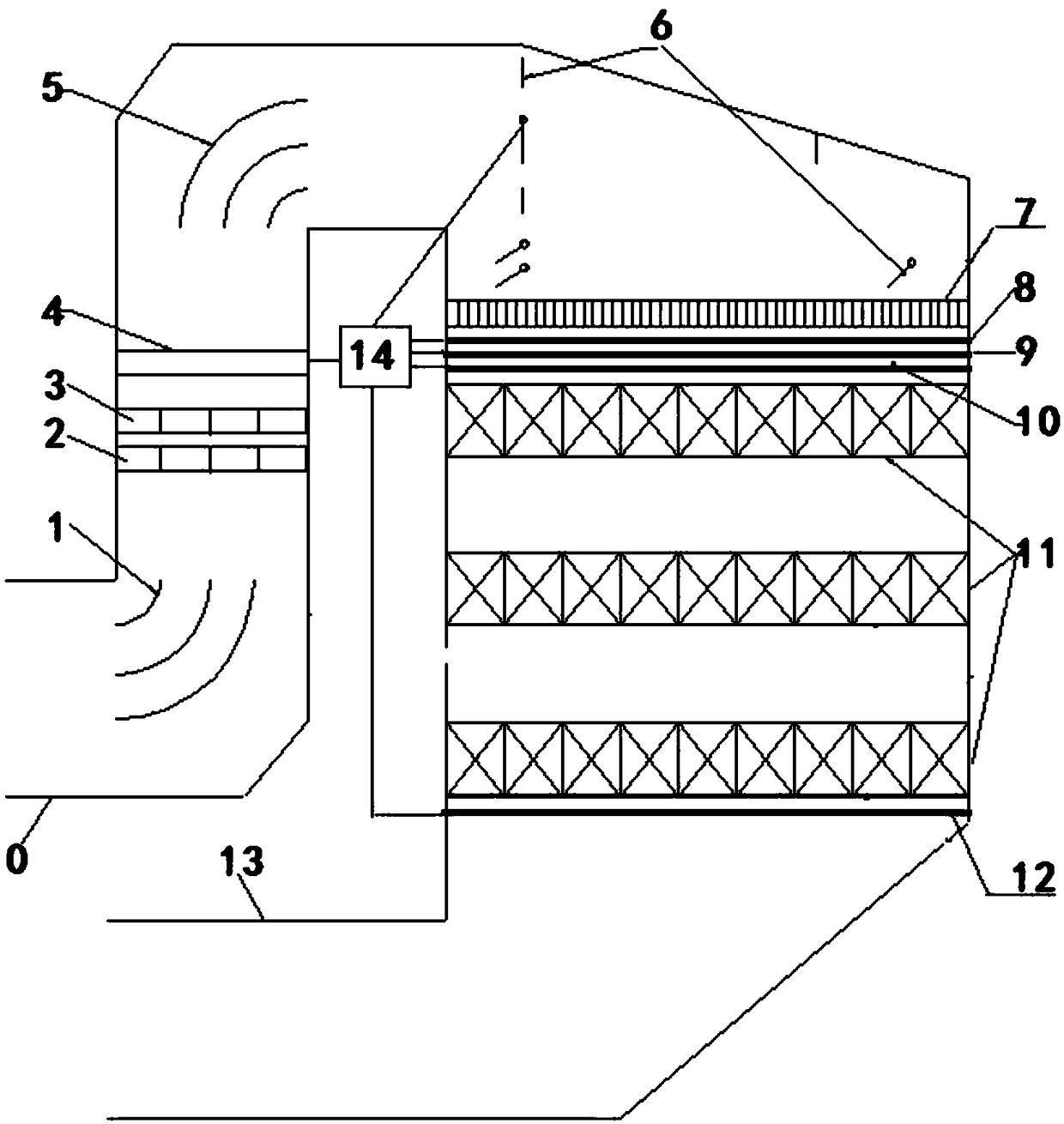

Full-load precise ammonia spraying system with functions of online speed field leveling and concentration field measuring

A technology of concentration measurement and concentration field, applied in the field of environmental treatment, to achieve the effect of improving denitrification efficiency, reducing ammonia injection volume and ammonia escape rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

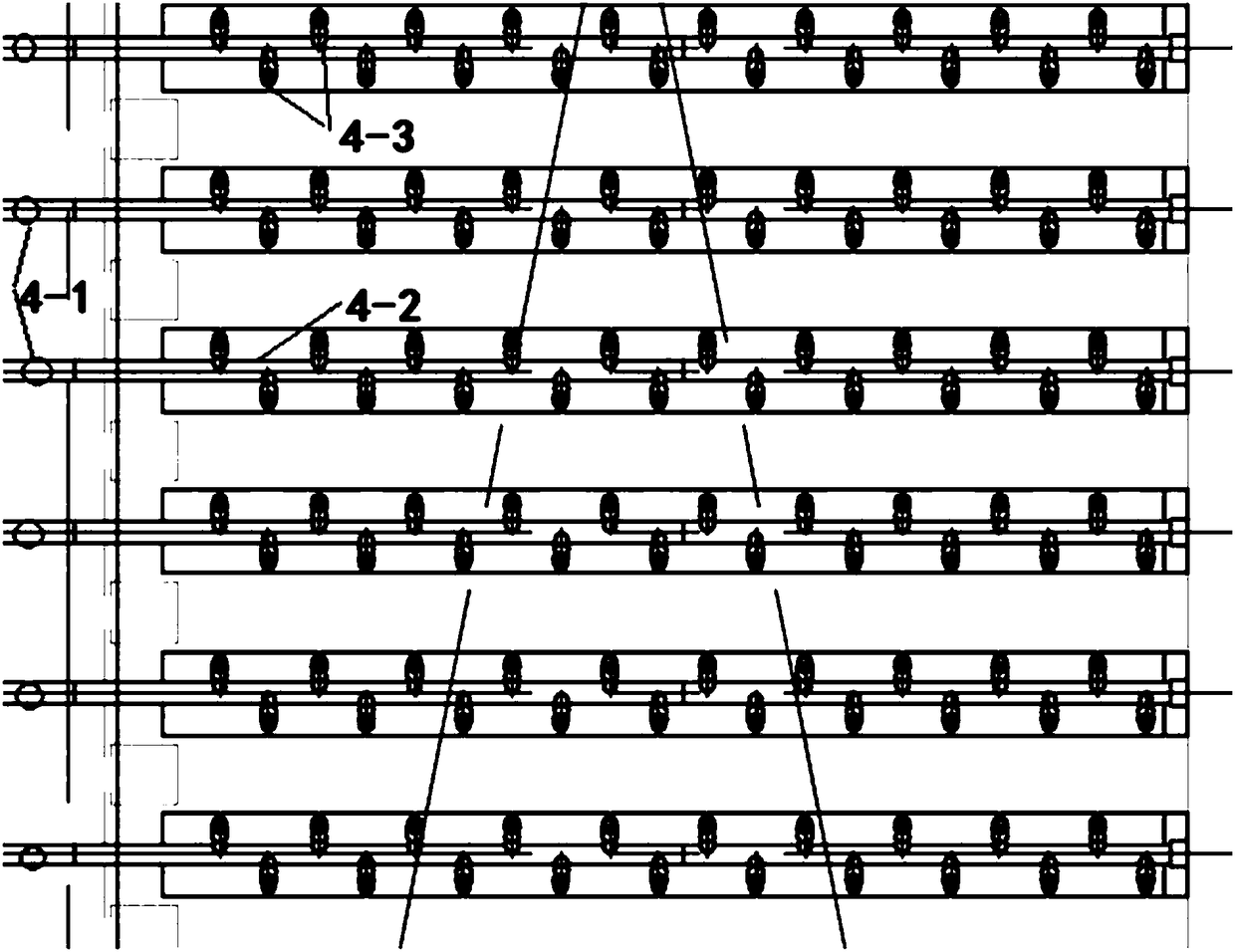

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Taking the SCR denitrification system of a 660MW supercritical unit in a power plant in Jiangsu as an example, there are currently problems with SCR: (1) NOx flow field at the outlet of SCR: There are many points of serious uneven distribution of NOx in both north-south and east-west directions ( The deviation exceeds 50%); (2) In some working conditions, there are multiple points of ammonia escape exceeding 3ppm; (3) The air preheater has been severely blocked many times, and it is forced to implement online water flushing of the air preheater during operation; (4) After low-level transformation, the above-mentioned problems are more prominent.

[0029] Since the SCR denitrification system of the power plant is divided into side A and side B, the configurations on both sides are exactly the same. Taking side A as an example, according to the content of the present invention, it is modified and installed with a full-load precision ammonia injection system bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com