Small turbine control system and method based on asynchronous motor full power converter speed regulation

A technology for small steam turbines and asynchronous motors, which is applied to generator control parts, machines/engines, and mechanical equipment, etc., can solve the problems of small opening of intake valve operating time, reduced power generation efficiency of power plants, and throttling loss, etc. Improve power generation efficiency and grid competitiveness, reduce throttling losses, and ensure the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

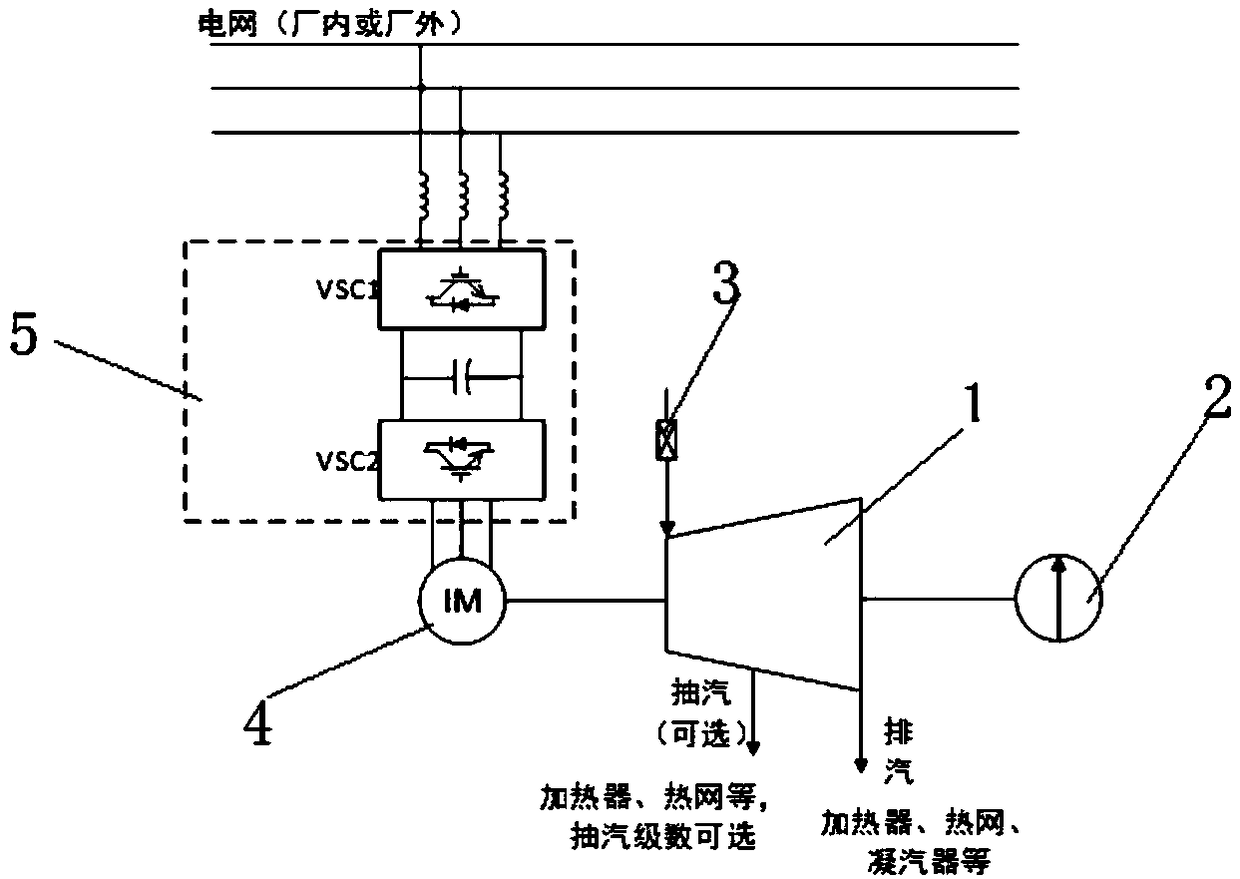

[0110] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0111] The technical solution of heat recovery small steam turbine with generator was proposed by East China Institute, which represents the world's leading steam extraction and heat recovery system solution, and is applied to supercritical and ultra supercritical units, especially the newly proposed 35MPa / 610~615℃ / 630℃ / 630℃ parameter class unit, can greatly improve the power generation efficiency of the unit, and make a new breakthrough in my country's secondary reheat coal-fired power generation technology.

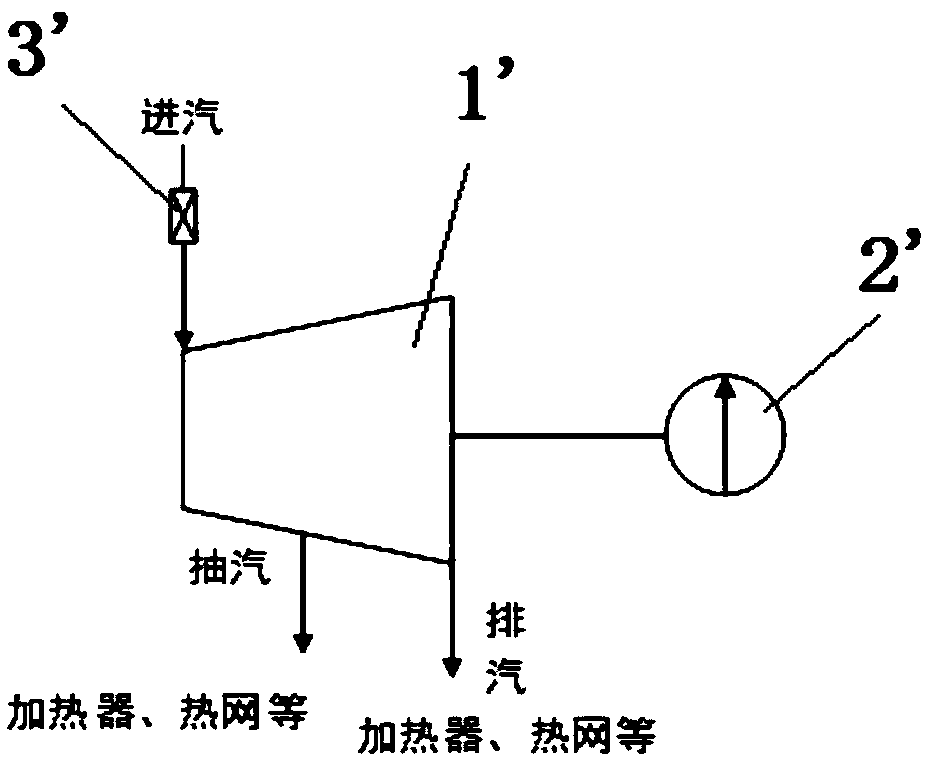

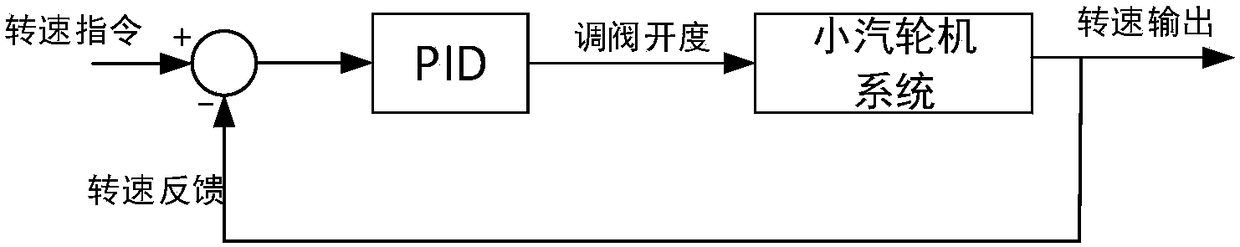

[0112] There are various configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com