Extraction regulation type turbo generator unit, load control method and primary frequency regulation method

A technology for steam turbine generator set and extraction steam regulation, which is applied to steam engine installations, engine components, machines/engines, etc., can solve problems such as throttling loss of steam flow, vibration of steam turbine shafting, etc., so as to reduce economic losses and reduce heat consumption. , the effect of reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

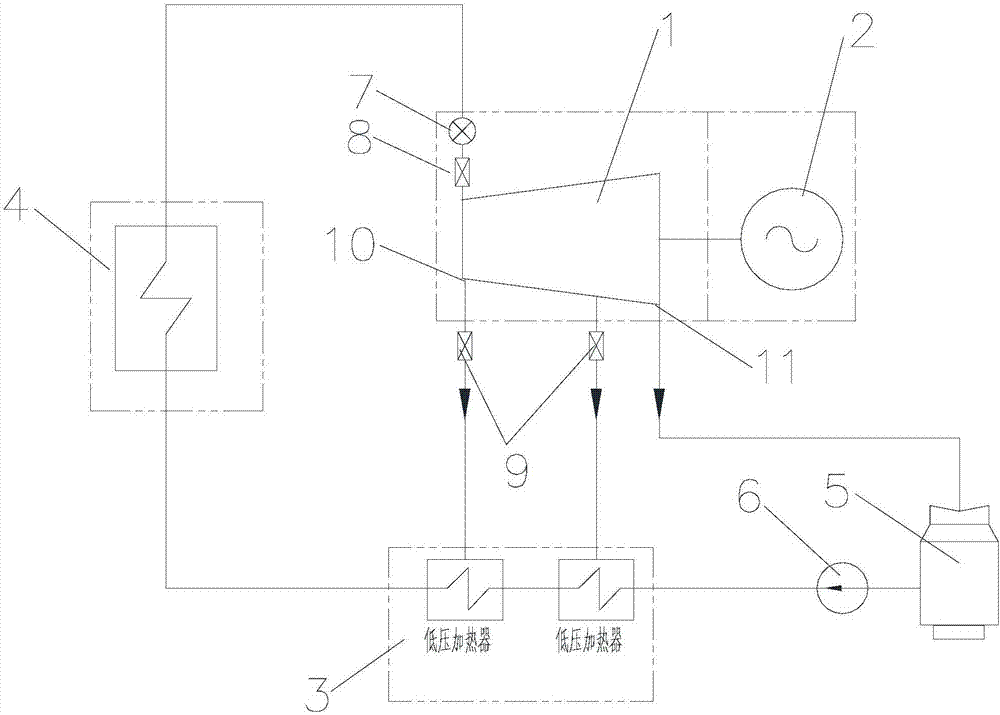

[0049] Such as figure 1 As shown, the turbogenerator set for steam extraction adjustment in this embodiment includes a steam turbine 1, a generator 2, a condenser 5, a low-pressure heating system 3 and a load regulation system, and the generator 2 is driven by the steam turbine 1, and the steam turbine 1 is equipped with There are steam extraction ports 10 and steam exhaust ports 11, and the steam extraction ports are respectively connected to the low-pressure heater in the low-pressure heating system 3 through steam extraction pipelines, wherein all steam extraction pipelines are equipped with extraction steam flow regulating devices 9, Of course, in practical applications, it is also possible to install the extraction steam flow regulating device only on part of the extraction steam pipeline according to the work requirements, which will not be described in detail here. The exhaust port is connected to the input port of the condenser 5 through the exhaust pipeline, and the o...

Embodiment 2

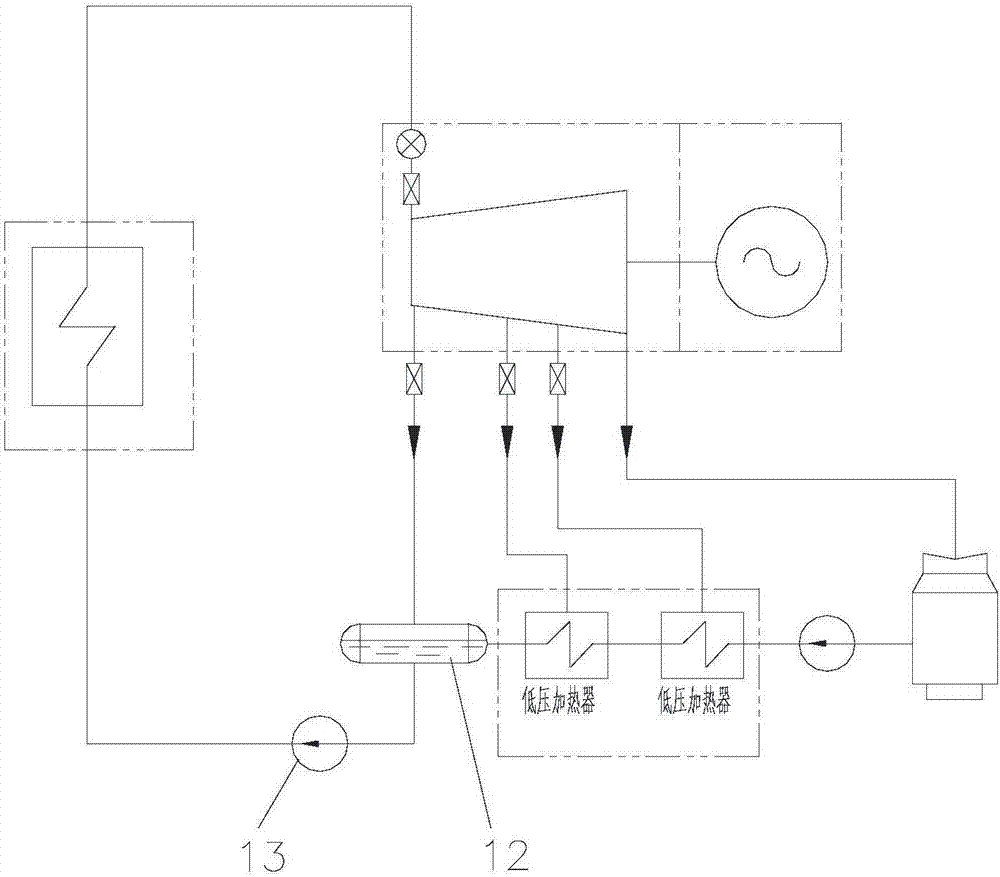

[0062] Present embodiment except following features other structures are with embodiment 1: see figure 2 , the present embodiment adds a deaerator 12 in the turbogenerator set regulated by steam extraction, the input end of the deaerator is respectively connected with the output port of the steam turbine and the output port of the low-pressure heating system, and the output end is connected with the deaerator through the deaeration pipeline. The boiler is connected, and a feed water pump 13 is provided on this pipeline.

[0063] The extraction steam flow regulating device may be installed on the connecting pipe between the deaerator and the turbine extraction steam. The extraction steam flow regulating device is connected with the load regulating system. The above-mentioned extraction steam flow regulating device can participate in the load regulation and primary frequency regulation functions of the steam turbine.

Embodiment 3

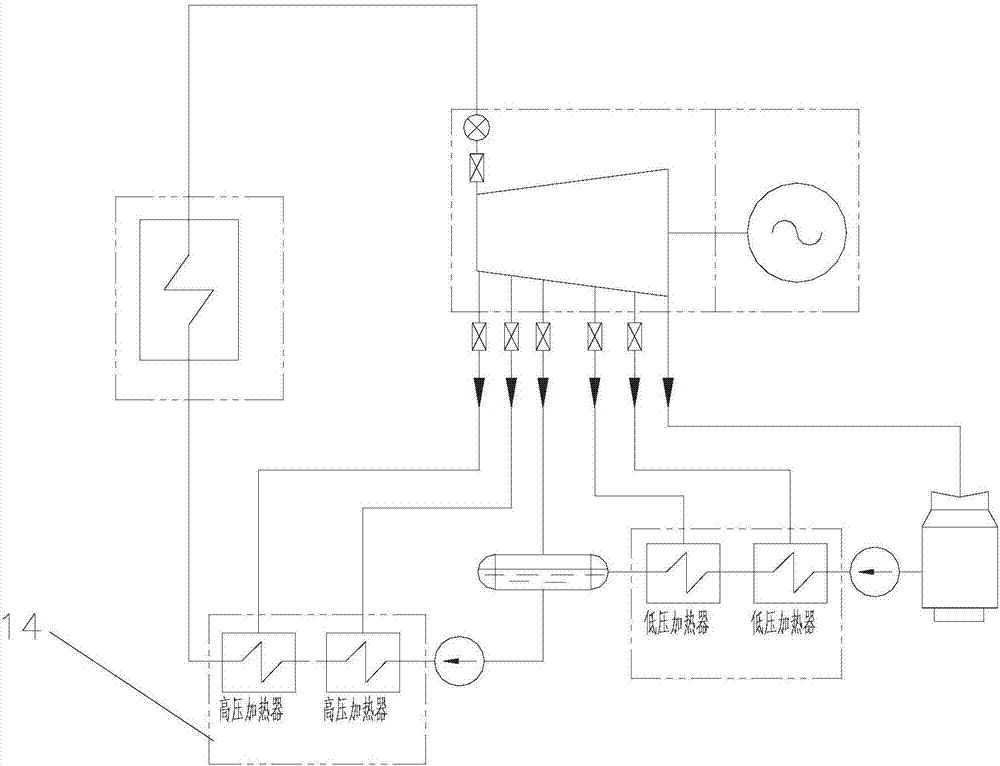

[0065] Other structures of this embodiment are the same as embodiment 2 except the following features: see image 3 In this embodiment, a high-pressure heating system 14 is added to the steam-extraction regulated steam turbine generator set. The high-pressure heating system is installed on the water supply pipeline. The input port is connected to the output port of the feed water pump, and the water side output port is connected to the boiler.

[0066] The high-pressure heating system 14 includes several high-pressure heaters connected in series, and an extraction steam flow regulating device may be installed on all or part of the steam extraction pipelines between the high-pressure heater and the steam turbine. The extraction steam flow regulating device is connected with the load regulating system. The above-mentioned extraction steam flow regulating device can participate in the load regulation and primary frequency regulation functions of the steam turbine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com