A kind of asphalt concrete additive and preparation method thereof

An asphalt concrete and additive technology, applied in the field of high-modulus asphalt concrete additives and its preparation, can solve the problems of insufficient anti-aging performance, weakening the low-temperature performance of asphalt mixture, reducing the low-temperature performance of asphalt concrete, etc. The effect of improving rutting resistance and low temperature performance, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

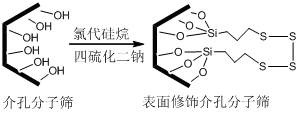

[0038] (1) 10 parts by weight of MCM-41 mesoporous molecular sieve (specific surface area is 1000 m) 2 / G), 0.4 parts by weight of sodium sodium sodium sodium sodium sulfide is added to 100 parts by weight of toluene. When heated to 50 ° C, 0.5 parts by weight of γ-chloropropyltrimethoxysilane was added dropwise, and the temperature was tapered to 70 ° C for 2 h, and then filtered, washed with ethanol, 100 ° C for 2 h, resulting in surface modified mesh molecular sieve.

[0039] (2) 100 parts by weight of high-density polyethylene (melt flow index of 2 g / 10 min), 10 parts by weight of polypropylene (melt flow index of 10 g / 10 min), 10 parts by weight of acetic acid-vinyl acetate copolymer (Melt fluid index is 35 g / 10min), 4 parts by weight of surface modified mesoporous molecular sieve, 2 parts by weight of 2,6-di-tert-butyl phenol is mixed, and the twin screw extruder is blended , Granulated, resulting in asphalt concrete additives. The extruder operating conditions were: a...

Embodiment 2

[0041] (1) 10 parts by weight of MCM-48 mesoporous molecular sieve (specific surface area is 800 m) 2 / g), 0.6 parts by weight of quadranium sodium sodium sodium sodium is added to 150 parts by weight of xylene. It was heated to 55 ° C, 0.8 parts by weight of γ-chloropropyltriethoxysilane, warmed to 75 ° C for 2 h, and then filtered, washed with ethanol, 100 ° C for 3 h, resulting in surface modified mesoporous molecular sieve.

[0042] (2) 100 parts by weight of high-density polyethylene (melt flow index of 8 g / 10 min), 20 parts by weight of polypropylene (melt flow index of 15 g / 10 min), 15 parts by weight of acetic acid-vinyl acetate copolymer (Melt Flow Index is 25 g / 10min), 5 parts by weight of surface modified mesoporous molecular sieve, 3 parts by weight of 4,4'-thiocyanis (6-tert-butyl-3-methylphenol) mixed, The blended extrusion is blended with a twin screw extruder to obtain asphalt concrete additives. The extruder operating conditions were: a period of 140 ° C; tw...

Embodiment 3

[0044] (1) 10 parts by weight of SBA-15 mesoporous molecular sieve (specific surface area is 1100 m) 2 / G), 0.7 parts by weight of sodium sodium sodium sulfide is added to 150 parts by weight of toluene. Heat until 60 ° C, 1.0 parts by weight of chloromethyl triethoxysilane, and the temperature was raised to 75 ° C for 3 h, and then filtered, washed with ethanol, 100 ° C for 5 h, resulting in surface modified mesoporous molecular sieve.

[0045] (2) 100 parts by weight of high-density polyethylene (melt flow index is 15 g / 10 min), 30 parts by weight of polypropylene (melt flow index is 10 g / 10 min), 20 parts by weight of acetic acid-vinyl acetate copolymer (Melt fluid index is 15 g / 10min), 6 parts by weight of surface modified mesh molecular sieve, 4 parts by weight of β- (3,5-di-tert-butyl-4-hydroxyphenyl) propionate isooctanol mixture After uniform, the blended extrusion is blended with a twin screw extruder to obtain asphalt concrete additives. The extruder operating cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com