Heavy-duty truck anti-rollover warning system based on sensing load

A technology of active braking and early warning system, applied in the direction of automatic starting device, control device, vehicle components, etc., can solve the problems of poor economy, less research literature on dynamic rollover, and difficulty in retrofitting of later devices, and achieves low stability, Easy to retrofit and the effect of reducing hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

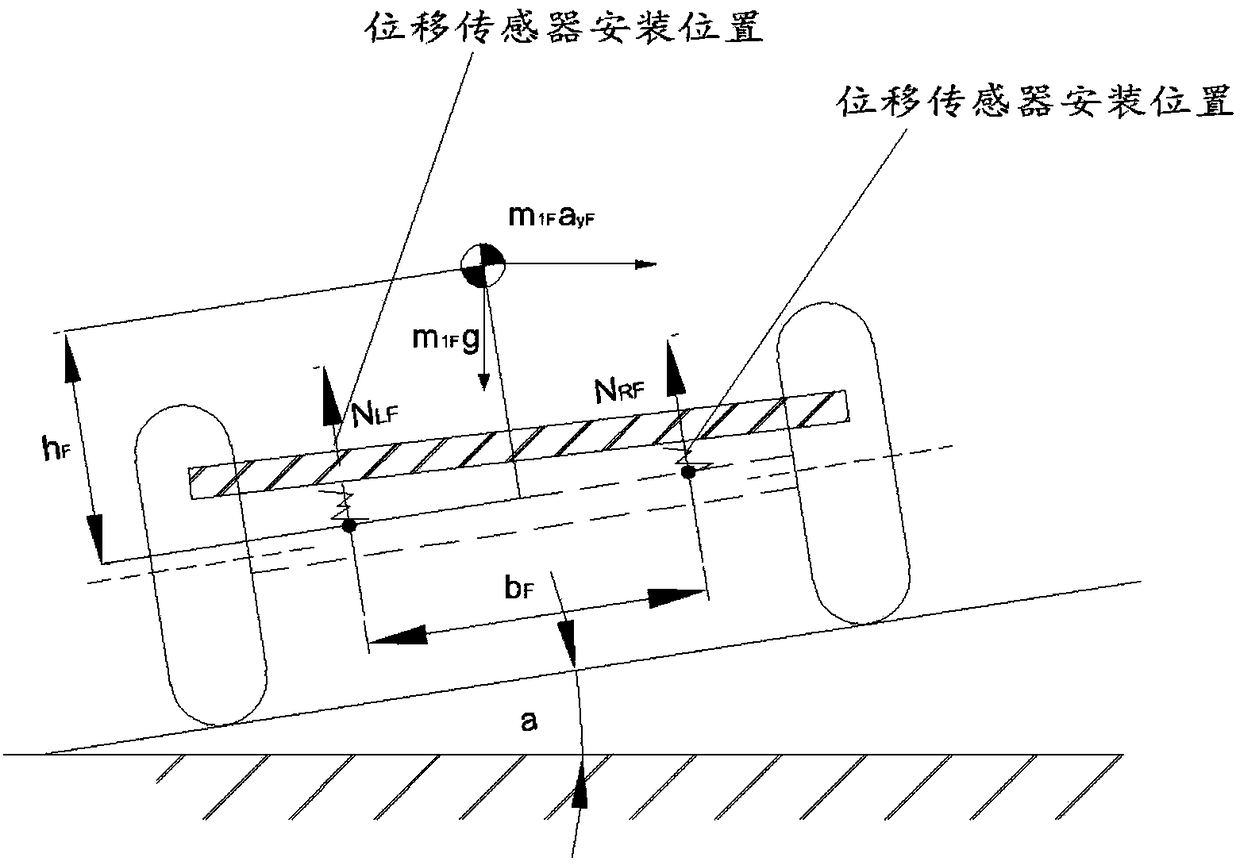

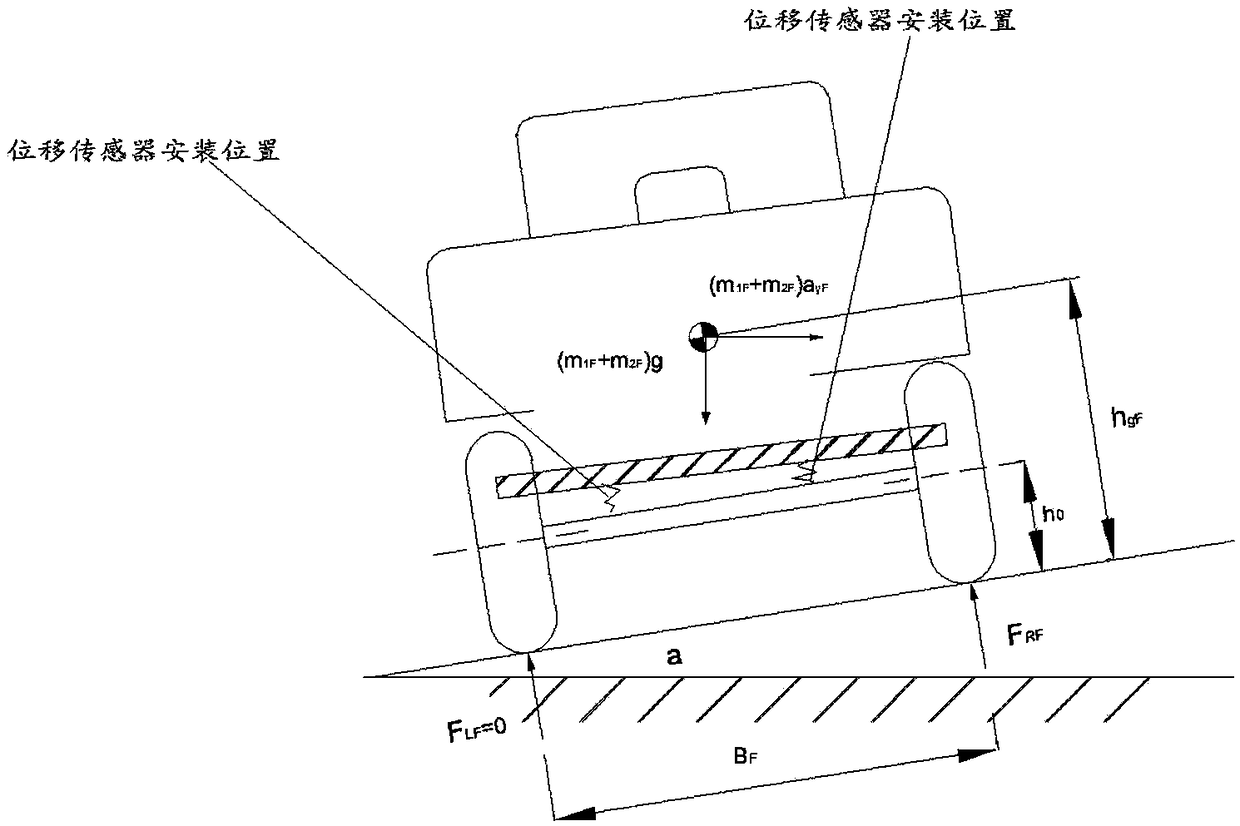

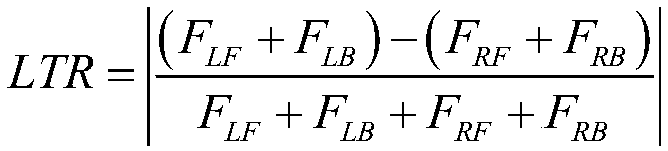

[0029] Such as figure 1 with figure 2 As shown, the anti-rollover early warning system for heavy vehicles based on perceived load and active braking uses the displacement sensor to receive the suspension displacement and the lateral acceleration sensor to receive the acceleration signal. The two signals are processed accordingly, and the calculated mechanical model is substituted into Calculate the values of the left front, left rear, right front and right rear support reaction forces; then substitute them into the lateral load transfer rate LTR model to calculate the real-time lateral load transfer rate, the specific steps are as follows:

[0030] (1) Install position sensors on the front, back, left and right springs to measure the real-time spring lengths of the front, back, left and right, according to the pressure value = spring stiffness coefficient and spring ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com