Novel dopamine salt and application thereof

A technology of dopamine and sodium salt, applied in the salt and preparation of dopamine and its preparation, application in the manufacture of drugs, preparation of the above salt and its preparation, dopamine sodium salt and potassium salt field, can solve human hyperchloremia, Low safety, large drug side effects and other problems, to achieve high safety performance, avoid hyperchloremia, and improve the effect of microcirculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of 1-methoxy-2-hydroxybenzaldehyde (compound 3)

[0046] Under the action of catalyst, p-hydroxybenzaldehyde (compound 1) is substituted with bromine to obtain 1-bromo-2-hydroxybenzaldehyde (compound 2); 1-bromo-2-hydroxybenzaldehyde (compound 2) is under alkaline conditions Under the substitution reaction with methanol, 1-methoxy-2-hydroxybenzaldehyde (compound 3) was obtained;

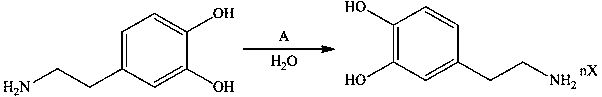

[0047] (2) Preparation of dopamine

[0048] 1-methoxy-2-hydroxybenzaldehyde (compound 3) undergoes Henry reaction under the condition of glacial acetic acid to obtain compound 4; compound 4 undergoes reduction reaction under the action of catalyst to obtain compound 5; compound 5 is prepared by heating in dilute sulfuric acid dopamine.

Embodiment 2

[0050]

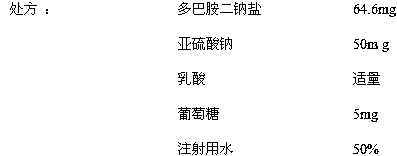

[0051] Weigh the prescribed amount of water for injection, and inject carbon dioxide into the water for injection for 25 minutes to saturation; then weigh dopamine disodium salt with a mass volume ratio of 64.6 mg / mL, sodium sulfite with a mass volume ratio of 50 mg / 100 mL, and sodium sulfite with a mass volume ratio of 64.6 mg / mL. Add 5g / 100mL of D-glucose monowater into the above-mentioned saturated water with carbon dioxide, stir and dissolve; add appropriate amount of lactic acid to the above solution to adjust the pH of the solution to 3.2~4.3, then add water for injection to the full amount and stir evenly; add Filter and sterilize with activated carbon at 15-35°C, fill the filtrate after passing the inspection, and sterilize at 121°C for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com