Making method of high-fiber bean crisp pastries

A production method and a technology for pastry, which are applied in the processing of dough, pre-baked dough, baking, etc., can solve the problems of single modification method, complicated operation, and the activity is affected by environmental factors, so as to improve the protein digestibility, improve the The taste of miscellaneous grains and the effect of purifying bad factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

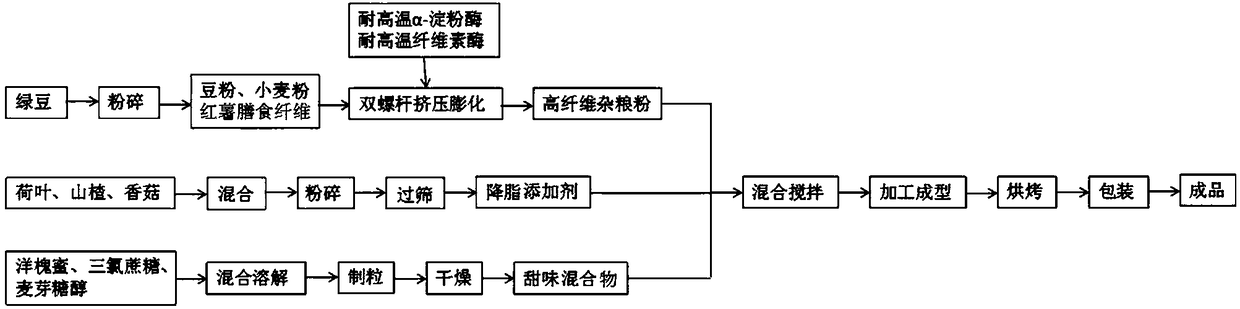

Method used

Image

Examples

Embodiment 1

[0030] (1) Select fresh and high-quality mung beans without gravel and insect eyes, wash them with clean water, put them into the pot, stir fry them continuously on low heat until the water is dry, immediately pour 2 times the volume of cold water to break the bean skins, and then boil on high heat for 2.5 Minutes to completely separate the bean skin, remove the bean skin to obtain dehulled bean grains, grind to 70 mesh, and obtain mung bean powder;

[0031] (2) Mix the above-mentioned mung bean flour with wheat flour (purchased from Lianhua Supermarket, the same as other examples) and sweet potato dietary fiber (purchased from Shaanxi Ciyuan Biotechnology Co., Ltd., the same as other examples) according to a mass ratio of 1:1:0.5 To obtain the raw material mixture, add 15U / g of high-temperature-resistant α-amylase (purchased from Shandong Anke Biological Engineering Co., Ltd., the same as other embodiments) and 30U / g of high-temperature-resistant cellulase (purchased from Wuha...

Embodiment 2

[0039] (1) Select fresh and high-quality mung beans without gravel and insect eyes, wash them with clean water, put them into the pot, stir fry them continuously on low heat until the water is dry, immediately pour 3 times the volume of cold water to break the bean skins, and then boil on high heat for 3 Minutes to completely separate the bean skin, remove the bean skin to obtain peeled bean grains, grind to 80 mesh, and obtain mung bean powder;

[0040] (2) Mix the above-mentioned mung bean flour with wheat flour and sweet potato dietary fiber according to a mass ratio of 1:2:1.5 to obtain a raw material mixture, add 20U / g of high-temperature-resistant α-amylase and 40U / g of high-temperature-resistant cellulase, wherein α- The quality of amylase and cellulase is respectively 2% and 3% of the mass of the raw material mixture, activated at 38°C for 60 minutes, adjusting the moisture content of the material to 15%, injecting into the twin-screw extrusion extruder, the front end o...

Embodiment 3

[0048] (1) Choose fresh and high-quality mung beans without gravel and insect eyes, wash them with clean water, put them into the pot, stir fry them continuously on low heat until the water is dry, immediately pour 3 times the volume of cold water to break the bean skins, and then boil on high heat for 2 Minutes to completely separate the bean skin, remove the bean skin to obtain peeled bean grains, grind to 80 mesh, and obtain mung bean powder;

[0049] (2) Mix the above-mentioned mung bean flour with wheat flour and sweet potato dietary fiber according to the mass ratio of 1:1.5:1 to obtain a raw material mixture, add 20U / g of high-temperature-resistant α-amylase and 30U / g of high-temperature-resistant cellulase, wherein α- The quality of amylase and cellulase is respectively 3% and 5% of the mass of the raw material mixture, activated at 34°C for 50 minutes, adjusting the moisture content of the material to 15%, and injecting it into the twin-screw extrusion extruder. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com