Separator for direct liquid feeding fuel battery

A fuel cell and separator technology, applied in fuel cells, fuel cell additives, fuel cell control, etc., to achieve the effects of improving reliability, simplifying structure, and enhancing integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiments.

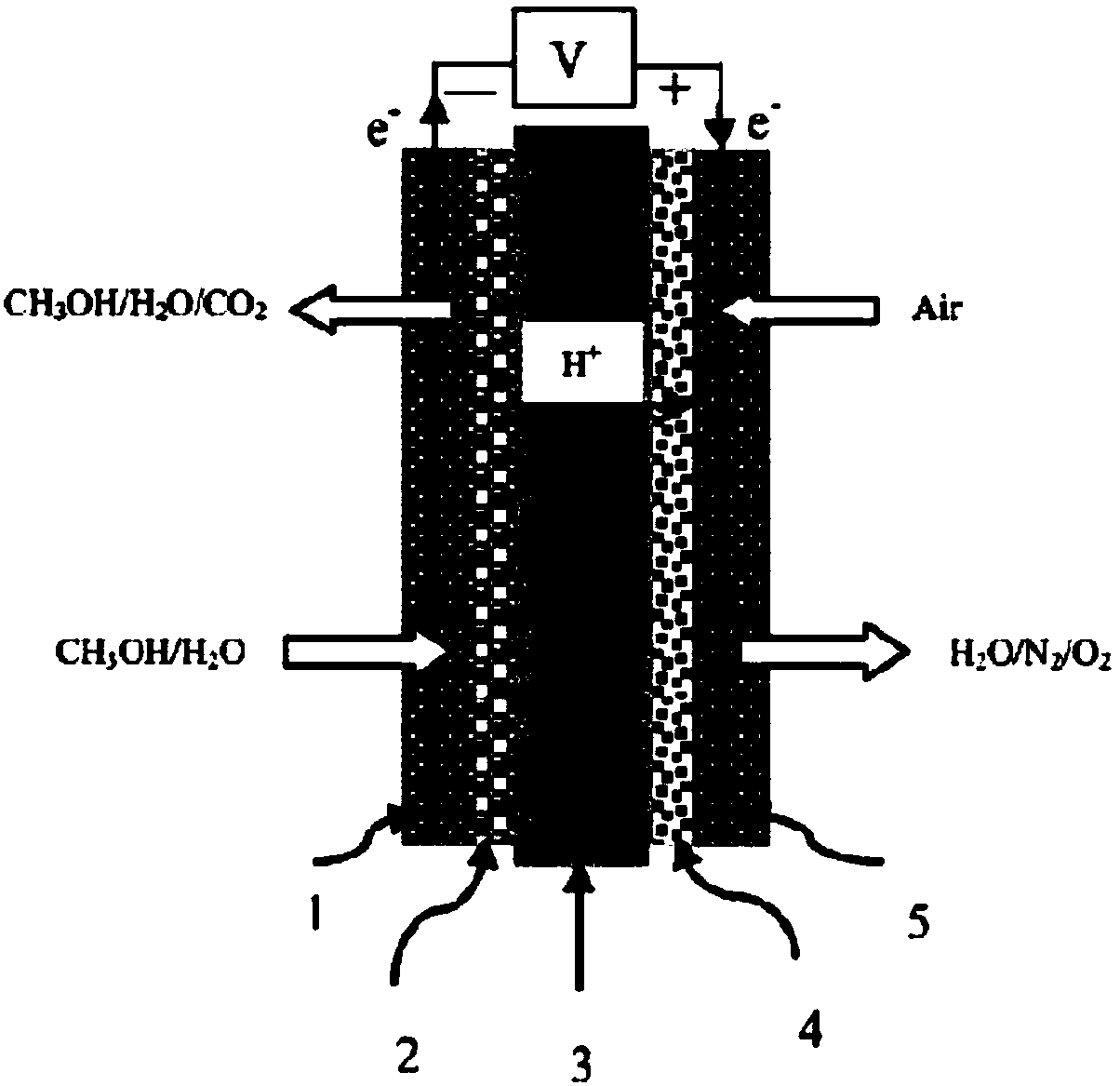

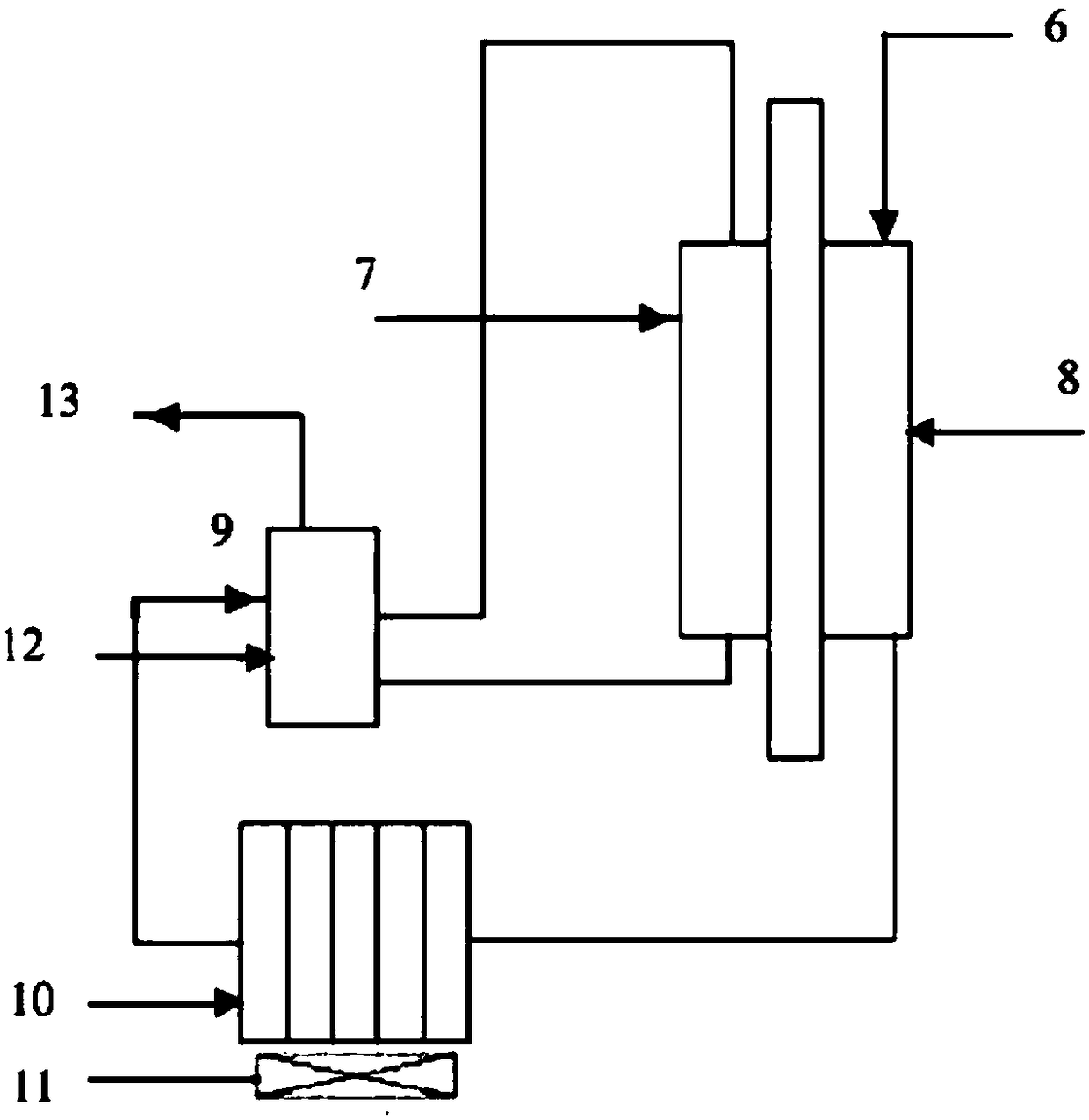

[0035] Such as figure 2 As shown, the direct liquid feed fuel cell system includes a direct liquid feed fuel cell such as a fuel cell stack, a separator that receives the anode diluted unreacted liquid fuel and CO produced by an electrochemical reaction 2 , and after the water and unreacted air produced by the cathode, the gas is vented to the atmosphere, the fuel pump that delivers the undiluted high-concentration fuel from the fuel tank to the separator, and the air pump that supplies air to the fuel cell stack, the cathode The resulting water is recycled to the separator.

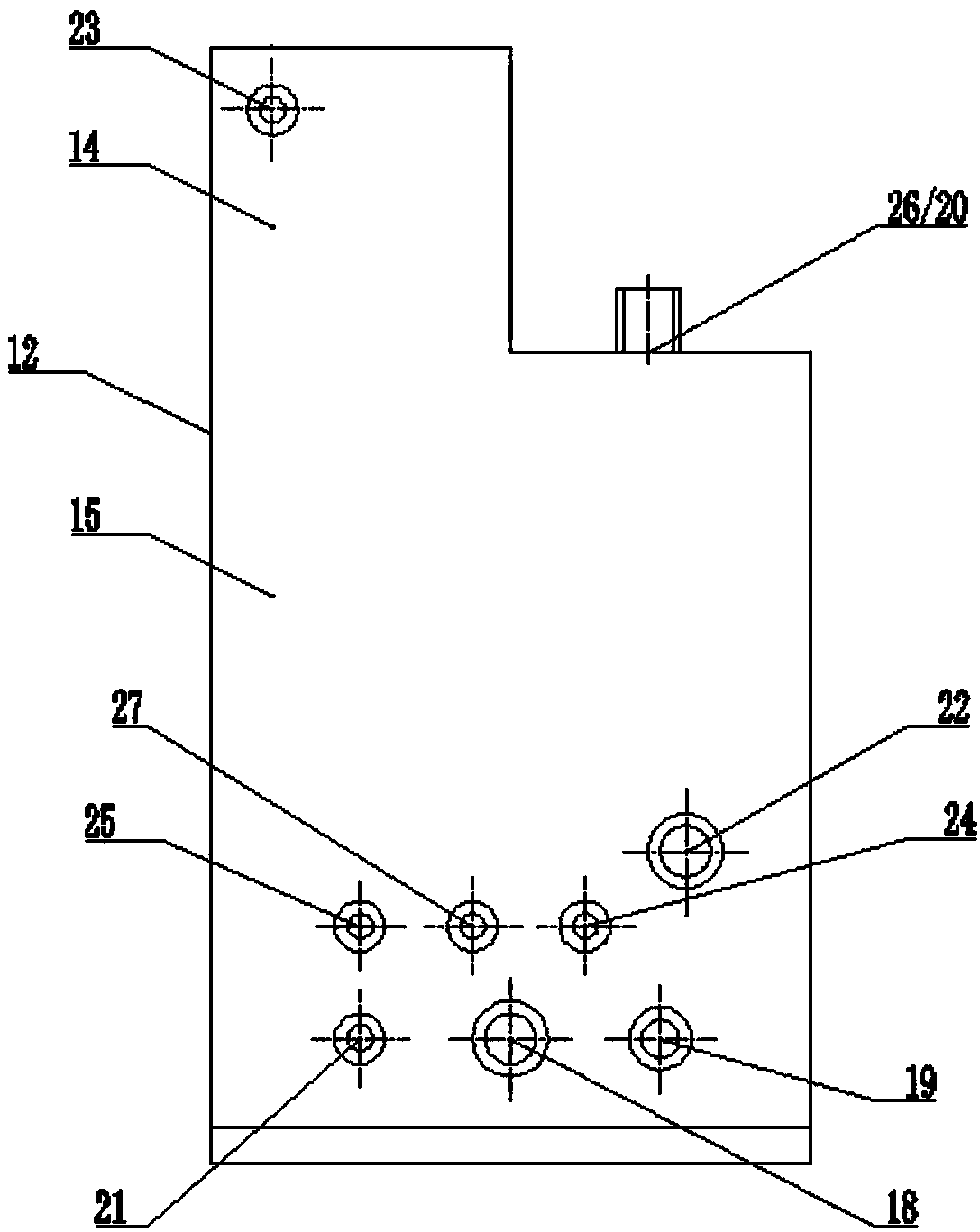

[0036] Such as image 3 , Figure 4 , Figure 5 , Figure 6 Shown is a separator for a direct liquid feed fuel cell, the separator 9 receives unreacted air / liquid water and CO produced from a direct liquid feed fuel cell system 2 / fuel mixture, and the liquid and gas are separated, which is ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com