Control method for electric excitation double-salient-pole motor without position sensor

A technology of electric excitation doubly salient and doubly salient motors, which is applied in the direction of electronic commutation motor control, control system, electrical components, etc., to achieve the effect of strong system structure, reliable operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

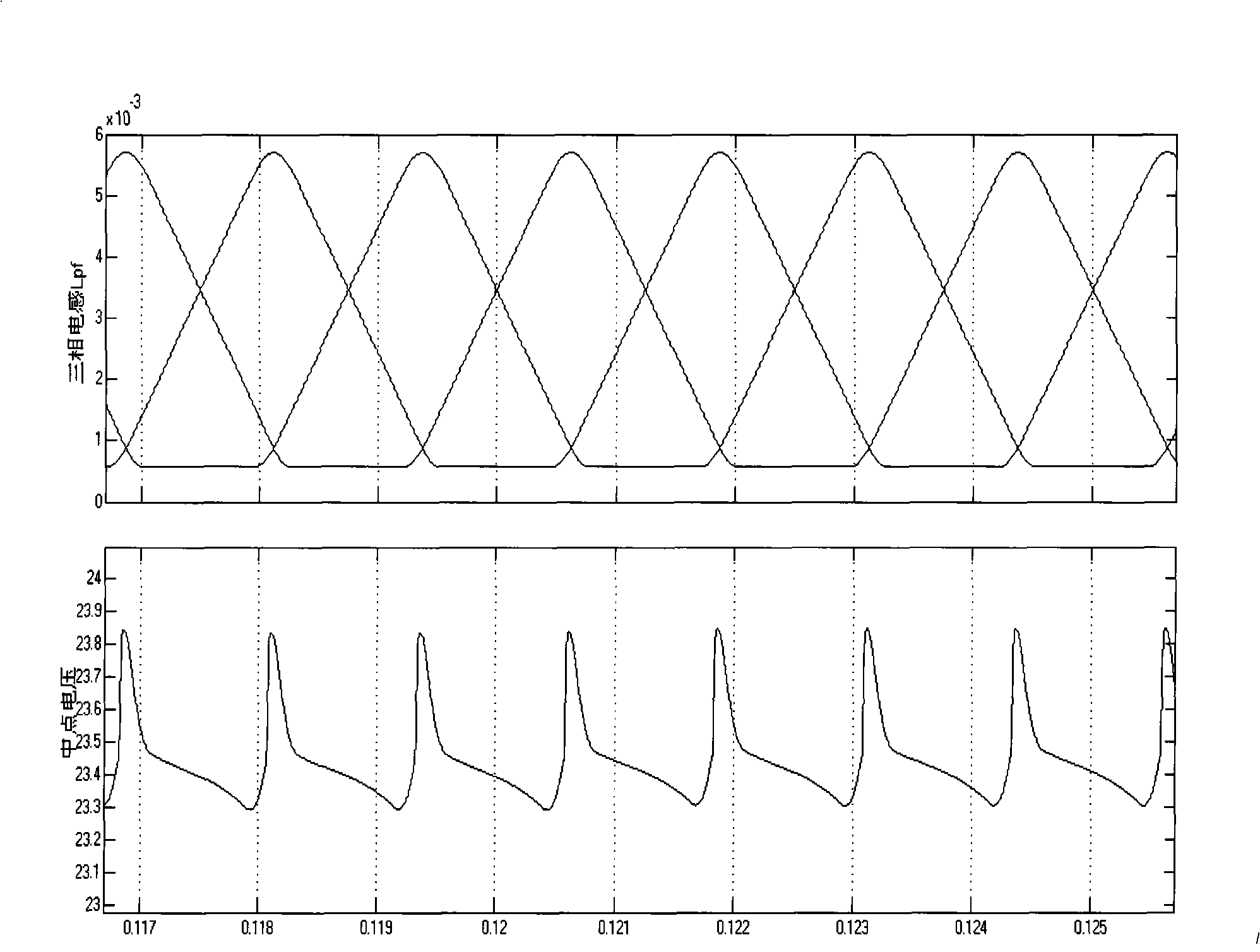

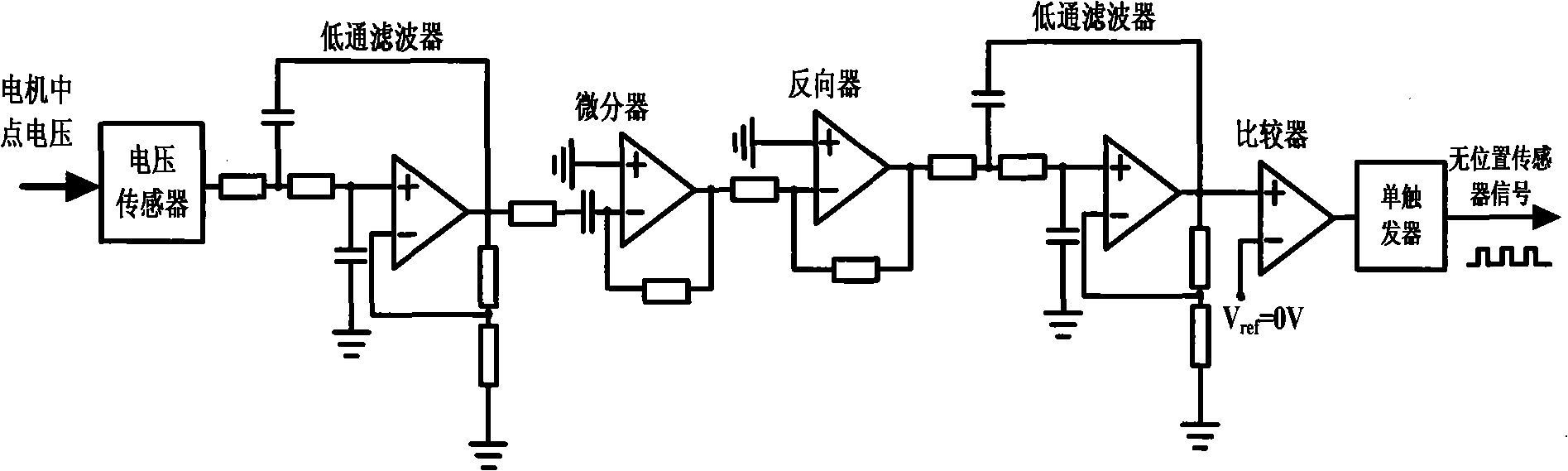

[0019] Such as figure 1 shown. The control method of the position sensorless electric excitation doubly salient pole motor of the present invention uses a power supply to provide current to the three-phase windings of the doubly salient pole motor, namely the A-phase winding, the B-phase winding and the C-phase winding through the inverter, including the following step:

[0020] a.) Initial positioning: The switch signal output by the main controller is used to pass through the inverter to any two-phase winding of the doubly salient motor to pass the switching current to make the rotor of the doubly salient motor rotate by a corresponding angle. In the winding: a positive current is passed into one phase winding, and a negative current is passed into the other phase winding;

[0021] b.) Accelerated start: output the offline commutation logic signal through the main controller through the given offline commutation pulse signal, and pass the offline commutation logic signal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com