Push and press gear

A gear and key tooth technology, applied in the field of large excavator gears in open-pit mines, can solve the problems of high processing and heat treatment costs, difficult processing and heat treatment of push gears, and failure to meet quality requirements, and achieve simplified heat treatment methods and clever design. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

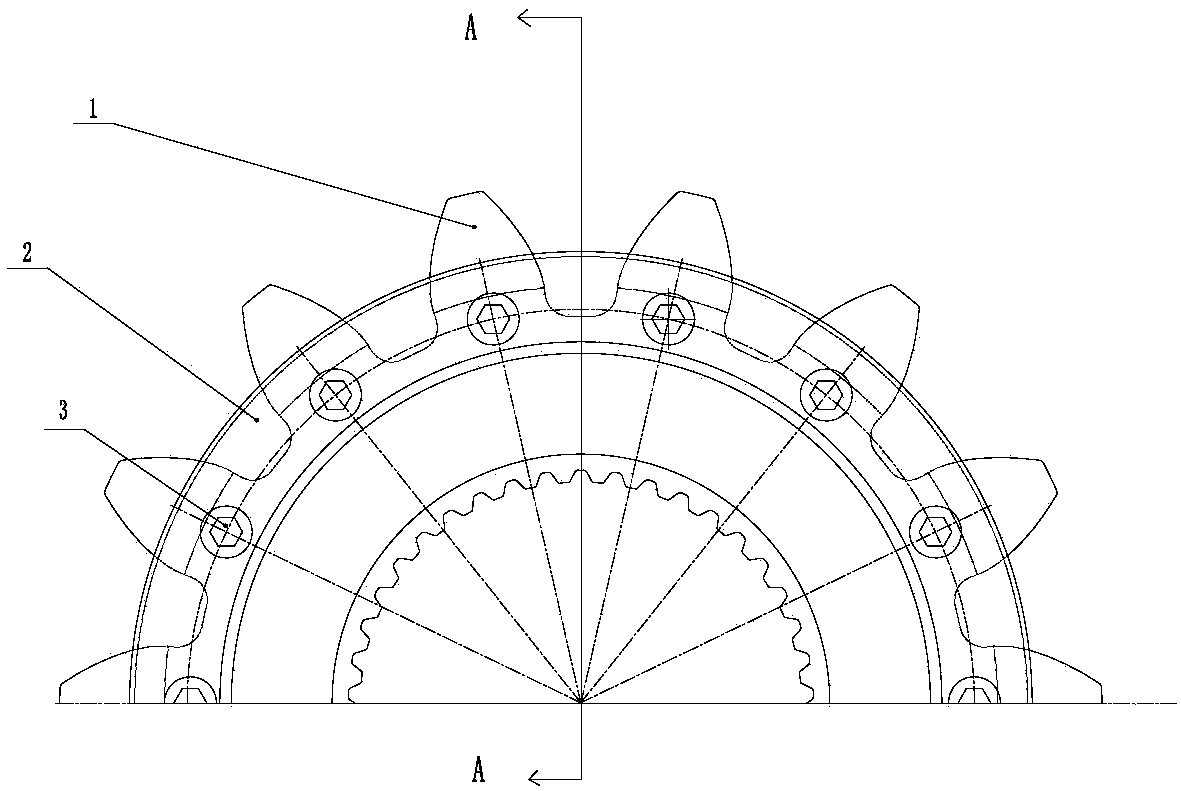

[0028] A pushing gear, including a gear 1, a flange 2, and a bolt 3,

[0029] The inner hole of the flange 2 is a two-layer stepped hole, which is divided into a spline hole 21 and a support hole 22 from large to small; the spline hole 21 is evenly distributed along the circumference with several keys protruding into the hole Teeth 211, key grooves 212 are formed between the key teeth 211, countersunk screw holes 23 are respectively provided on the walls of the support hole 22 corresponding to several key grooves 212;

[0030] On the sidewalls of both axial ends of the gear 1, a stepped step 14 and a corresponding key tooth 11 are provided corresponding to the two-layer stepped hole of the flange flange 2, and the key tooth 11 is provided with a corresponding countersunk head. The screw hole 12 of the screw hole 23, the flange flange 2 is respectively installed at both ends of the gear 1, the step 14 of the two-layer stepped hole is fitted, and the key teeth 211 are embedded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com