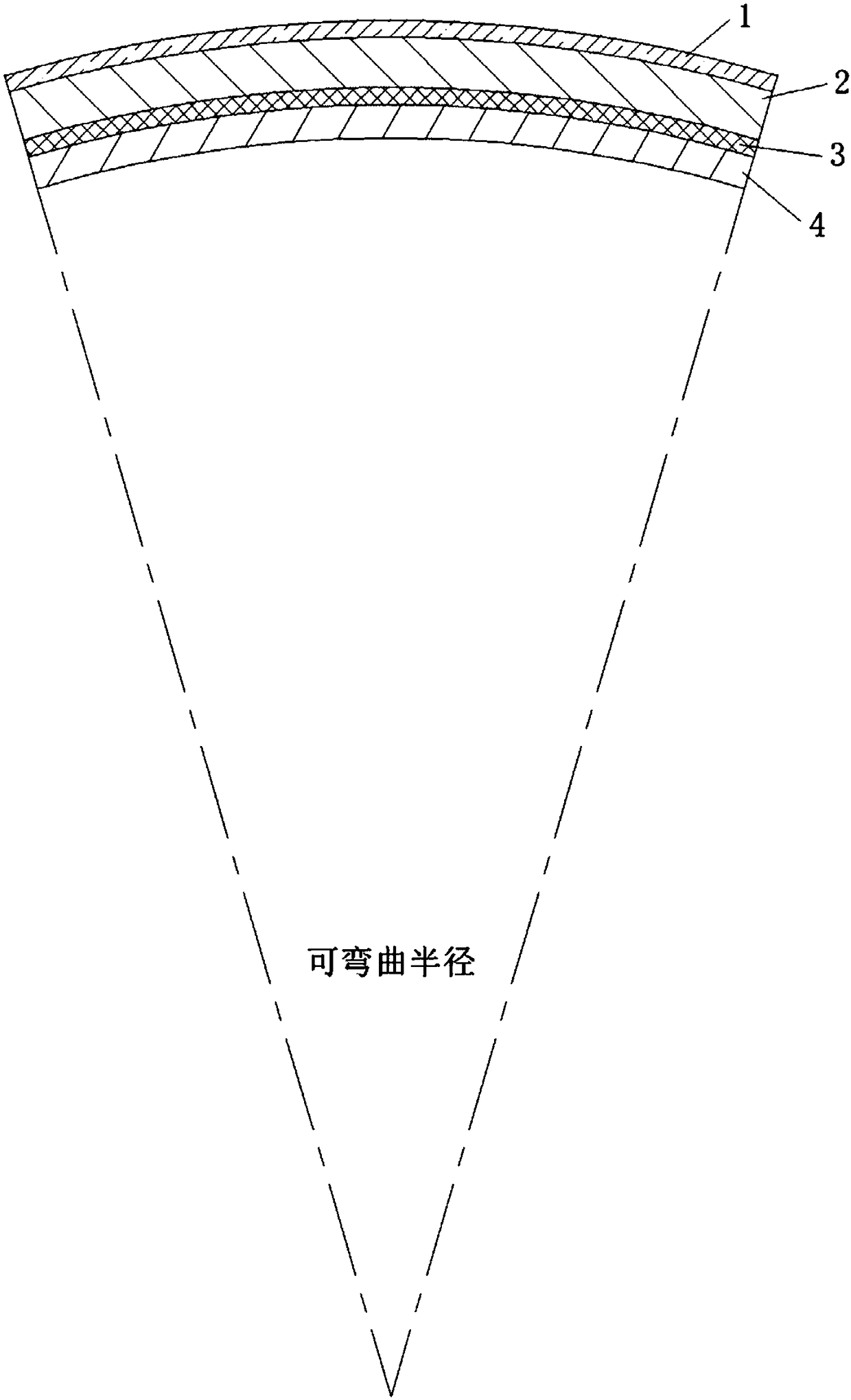

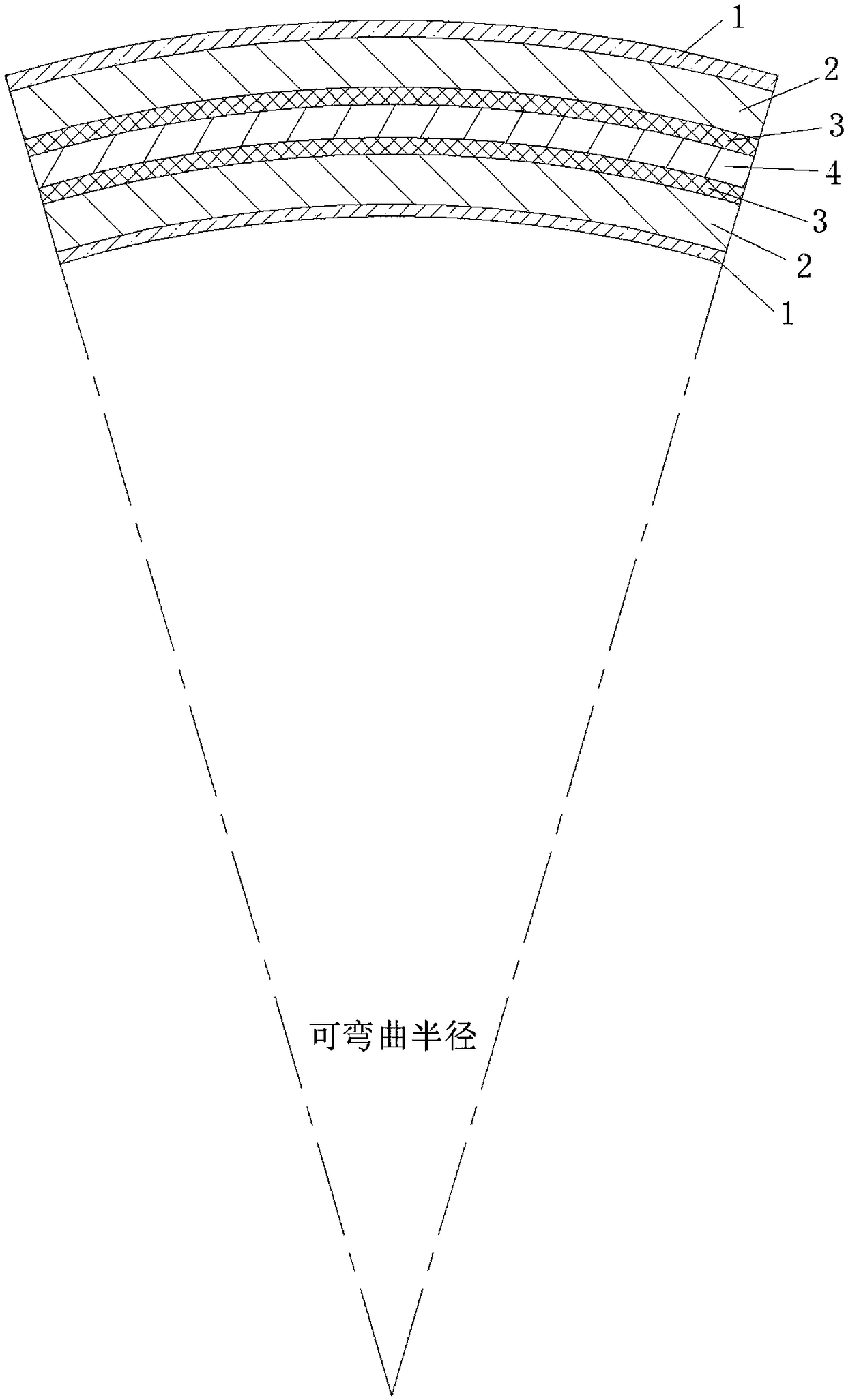

Ultrathin flexible stone composite board and manufacturing method thereof

A manufacturing method and technology of composite boards, which are applied in chemical instruments and methods, lamination auxiliary operations, and other household appliances, can solve the problems of destroying natural resources, reducing impact resistance, and being prone to breakage, so as to save natural resources, The overall thickness is low and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] The manufacturing method of the ultra-thin flexible stone composite board comprises the following steps:

[0032] Step 1. Pretreatment of raw materials, smoothing the surface of the natural stone, then drying the natural stone, and cleaning the surface of the flexible substrate;

[0033] Step 2, gluing treatment, apply adhesive on the surface of the natural stone and the flexible substrate, the adhesive constitutes to bond the two together to form a stone composite board;

[0034] Step 3, curing treatment, pressurizing and curing the stone composite board for 48 hours;

[0035] Step 4, sizing treatment, the fixed length, fixed width and fixed thickness treatment of the surface of the stone composite board after pressurization and curing;

[0036] Step 5, polishing treatment, finely grinding and polishing the surface of the stone composite board...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com