Process for preparing biodiesel from Monopodella cells

一种生物柴油、单针藻的技术,应用在单细胞藻类、基于微生物的方法、微生物等方向,能够解决成本高、生物柴油效率低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The technique for preparing biodiesel by utilizing Monopodella cells comprises the steps of:

[0032] Streak inoculation of Cellulomonas xanthogenes on the slant medium to obtain a single colony; pick a single colony and inoculate it on the primary seed medium for cultivation, and then culture it on the secondary seed medium to obtain Cellulomonas xanthogenes Bacteria seed liquid; the components of the slant medium are: yeast extract 50g / L, glucose 30g / L, agar 20g / L; the components of the primary seed medium and the secondary seed medium are: corn flour 30g / L, glucose 20g / L, ammonium nitrate 1g / L, magnesium sulfate heptahydrate 0.2g / L, potassium dihydrogen phosphate 0.3g / L, dipotassium hydrogen phosphate 0.3g / L, ferrous sulfate heptahydrate 0.1g / L L;

[0033] Pick Monotipella, plant them in a container containing growth medium, light intensity 5000lux, light-dark cycle 24h, light-dark ratio 14:10, cultivate at 28°C, grow to the logarithmic growth phase, and get Monotip...

Embodiment 2

[0038] The technique for preparing biodiesel by utilizing Monopodella cells comprises the steps of:

[0039] Streak inoculation of Cellulomonas xanthogenes on the slant medium to obtain a single colony; pick a single colony and inoculate it on the primary seed medium for cultivation, and then culture it on the secondary seed medium to obtain Cellulomonas xanthogenes Bacteria seed liquid; the components of the slant medium are: yeast extract 50g / L, glucose 30g / L, agar 20g / L; the components of the primary seed medium and the secondary seed medium are: corn flour 30g / L, glucose 20g / L, ammonium nitrate 1g / L, magnesium sulfate heptahydrate 0.2g / L, potassium dihydrogen phosphate 0.3g / L, dipotassium hydrogen phosphate 0.3g / L, ferrous sulfate heptahydrate 0.1g / L L;

[0040] Pick Monotipella, plant them in a container containing growth medium, light intensity 5000lux, light-dark cycle 24h, light-dark ratio 14:10, cultivate at 28°C, grow to the logarithmic growth phase, and get Monotip...

Embodiment 3

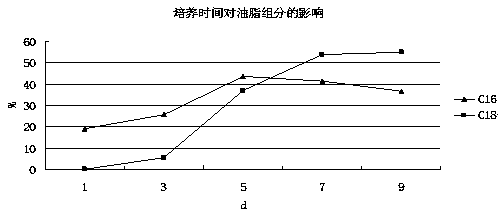

[0052] The present invention has detected the influence of culture time on fatty acid components in oil:

[0053]The fatty acid composition of different algae species is very different, and the content of C16 and C18 is an important factor to determine the performance of oil. Taking Example 1 as an example, set the time gradient as 1, 3, 5, 7, 9 (d), and analyze the oil composition by GC-MS. The fatty acids produced by Monostipella during heterotrophic culture are mainly C16 and C18 . Such as figure 1 As shown, there is only a small amount of C16 in the early stage of culture, and as the culture time increases, the content of C16 increases, reaches the peak on the 5th day, and then decreases, but the decline is not large; C18 begins to be produced on the 3rd day , and then increased rapidly, and the increase was not obvious after the 7th day. Considering the cost and time of cultivation, it is most appropriate to choose to cultivate for about 7 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com