Adhesive for sunglass surface membrane and preparation method thereof

A technology for adhesives and glasses, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of firmness and light transmittance, and achieve the effect of significant technological progress and high-strength adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 (this adhesive production process)

[0026] The invention provides an adhesive for sunglasses mirror film, which is composed of the following raw materials in mass percentage:

[0027]

[0028]

[0029] Described first base resin is thermoplastic polyurethane, and its structural formula is:

[0030] -[OCNH-R-NHCO-OR’-O] n -, 1000

[0031] Described second base resin is thermoplastic polyurethane, and its structural formula is:

[0032] -[OCNH-R-NHCO-OR’-O] n -, 2000

[0033] Specifically, the first base resin is thermoplastic polyurethane, and its structural formula is:

[0034] -[OCNH-R-NHCO-OR’-O] n -, n=2500; R is phenyl

[0035] Described second base resin is thermoplastic polyurethane, and its structural formula is:

[0036] -[OCNH-R-NHCO-OR’-O] n -, n=4000, R is phenyl.

[0037] The present invention also provides the preparation method of the above-mentioned adhesive for the mirror film of sung...

Embodiment 2

[0040] Embodiment 2 (this adhesive using method)

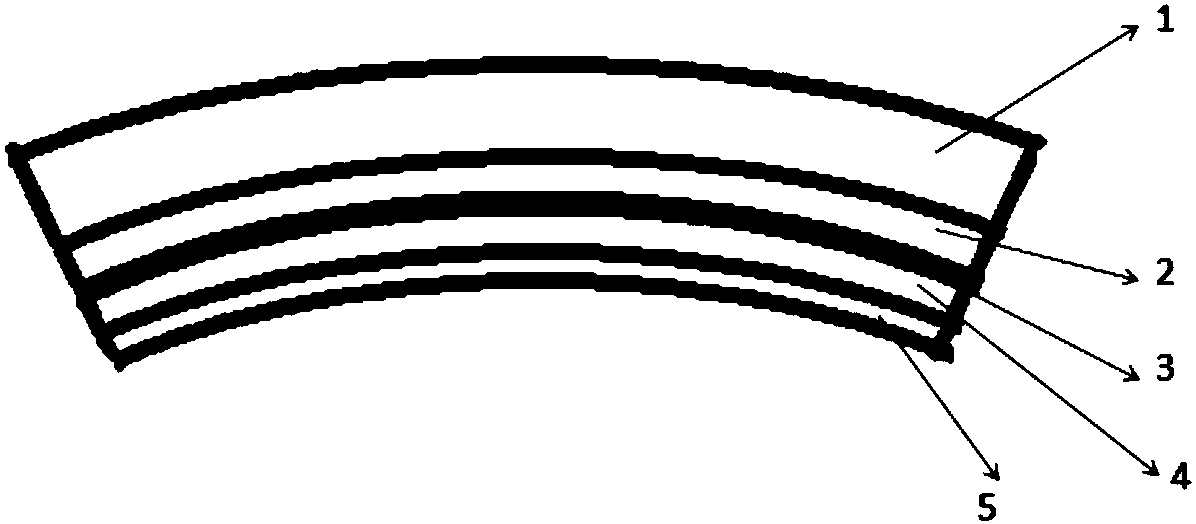

[0041] Such as figure 1 As shown, the adhesive for the mirror film of sunglasses of the present invention can be attached to the mirror film 3 by wetting or coating, thereby forming the adhesive layer 2 and the adhesive layer 4, which are respectively connected with the lens resin monomer (outside ) 1 and the lens resin monomer (inside) 5 form a finished lens with a bonding interface with high light transmittance and high bonding strength in an oven at 80 degrees Celsius.

[0042] The lens resin monomer (outer) 1 and the lens resin monomer (inner) 5 are generally made of CR39 material, the outer thickness is 1-10 mm, and the inner thickness is 100-500 nanometers. The mirror film 3 is generally made of CR39 material with a thickness of 1-300 nanometers.

Embodiment 3

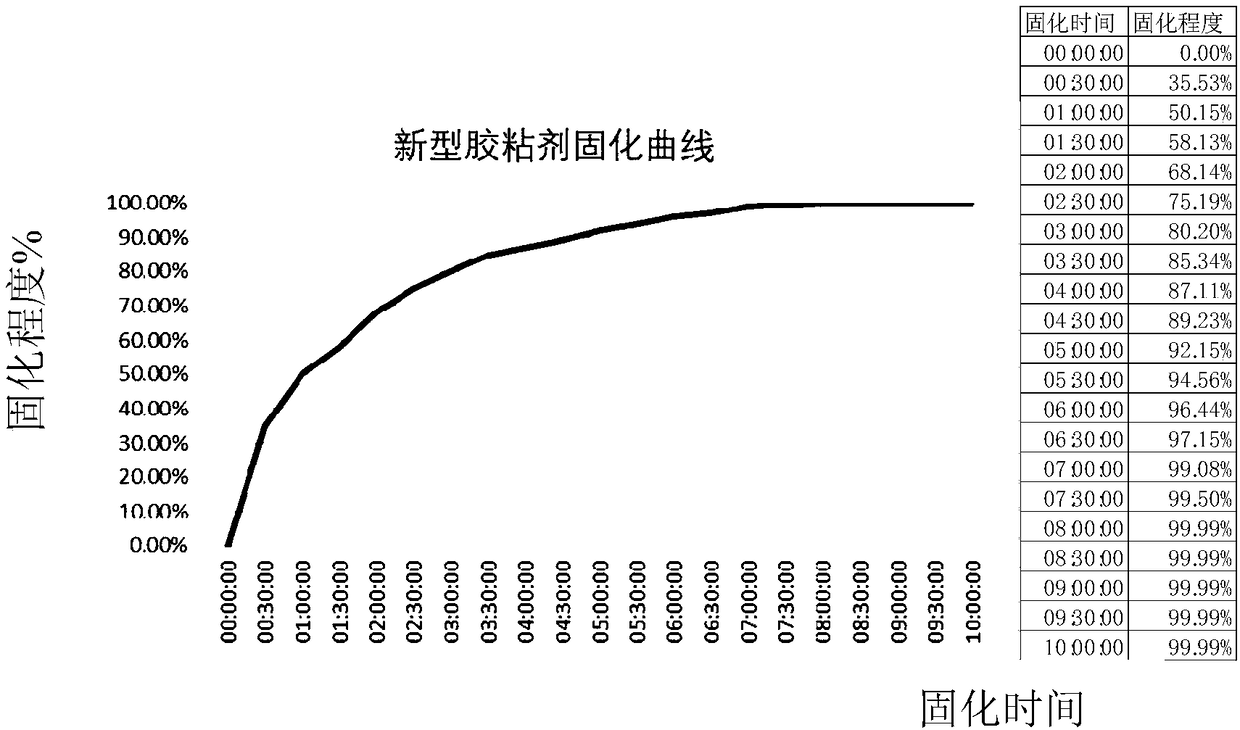

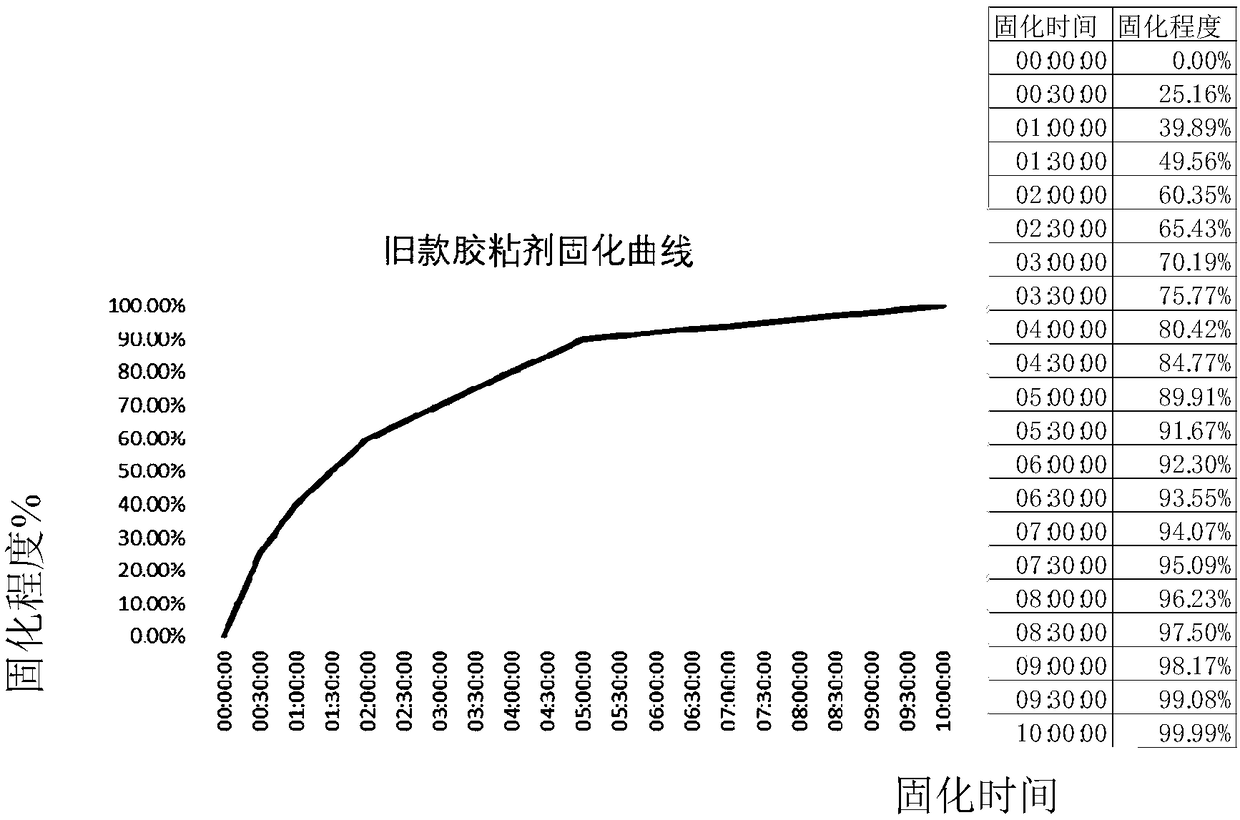

[0043] Example 3: (this adhesive performance "curing curve" test method)

[0044] 1) Prepare 40 samples respectively, inject the monomer into the reaction mold, and fill the homogeneous monomer liquid on both sides of the mirror film soaked in the adhesive prepared by the method in Example 1.

[0045] 2) Take out two samples every half hour, observe the curing situation and detect the refractive index by the minimum deviation angle method.

[0046] 3) Calculation degree of curing = instant refractive index / refractive index after complete curing.

[0047] Experimental data:

[0048] figure 2 with image 3 The curing curve is based on the instant refractive index / refractive index after complete reaction as the evaluation standard. It can be seen that the curing efficiency of the new adhesive is obviously better than that of the old adhesive, and it can be fully cured within the processing period to improve the adhesion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com