A kind of art gouache pigment containing nanometer composition and its manufacturing method

A gouache paint and art technology, applied in the field of art gouache paint and its manufacturing, can solve the problems of loss of artistic charm and value of works, poor chemical stability of gouache paint, shortened shelf life, etc., and achieve excellent color quality, excellent stability, color and so on. lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

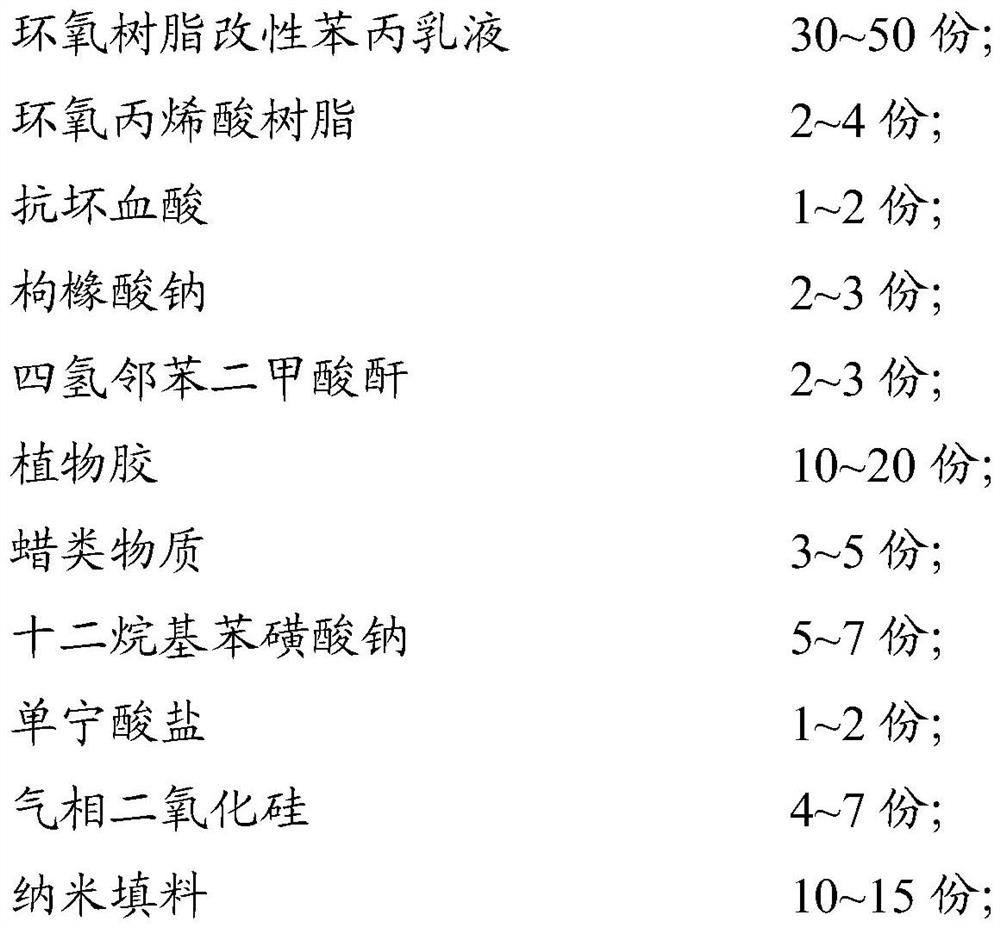

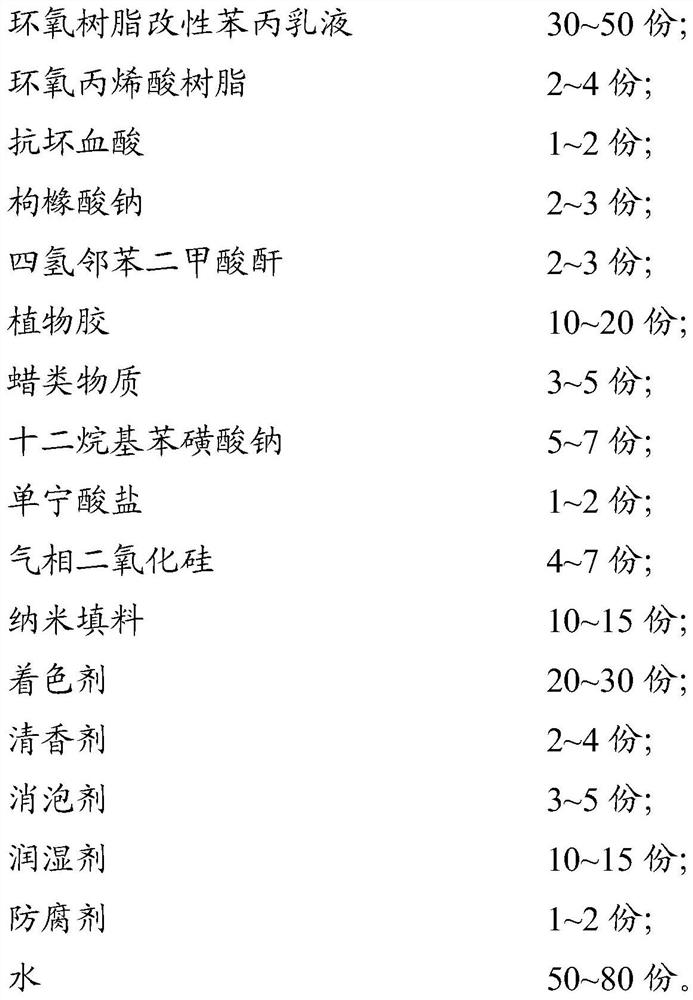

[0063]Artwater powder containing nanochemistry, including raw materials of the following weight parts:

[0064]34 epoxy resin modified benzide emulsions, 3.5 serial oxygen resin, 1.2 parts of ascorbic acid, 2.4 sodium citrate, 2.2 parts of tetrahydrodeenzene terephthalic anhydride, 10 plants, 3.5 pieces of paraffin, 5.5 parts Twelvelycene sulfonate, 1.3 servantic acid calcium, 5 parts of gas phase silica, 12 nano fillers, 24 parts of organic pigment powder, 2.8 fragrant antibodies, 3.7 parts of oleate, 12 parts of propylene glycol, 1.2 parts of calcicy sulfate and 75 parts of water;

[0065]The particle size of gas phase silica is 20 to 40 nm;

[0066]Plant gums include a mass ratio of 4.8: 1.3: 2.3: 3.5: 1.3: 0.5 pectin, malturol, karaperg, starch, maltodextrin, and pre-adhesive starch;

[0067]Nanofillers include a mass ratio of 0.6: 1: 1: 0.5: 0.5: 2.4, a titanium powder, leaf wax powder, calcium carbonate and ceramic fine powder; the particle size of the uneven rod and the leaf wax powder i...

Embodiment 2

[0075]Artwater powder containing nanochemistry, including raw materials of the following weight parts:

[0076]46 epoxy resin modified benzide emulsions, 4 serial oxygen resins, 1.8 parts of ascorbic acid, 2.8 sodium citrate, 2 parts of tetrahydrodoric anhydride, 20 plants, 3.8 microcrystalline wax, 6.3 parts of sodium dodecyl benzene sulfonate, 1.4 parts of tannic acid zinc, 6 gas phase silica, 11 nano filmers, 22 parts of inorganic pigment powder, 2 fragrant agents, 3.4 parts of polyimethylsiloxane , 11-parts of diol, 1.8 parts of hydrochloride and 80 parts of water;

[0077]The particle size of gas phase silica is 20 to 40 nm;

[0078]Plant gums include a mass ratio of 4: 1.2: 2.7: 3.3: 1.7: 0.75 pectin, malturol, karam, starch, maltodextrin, and pre-adhesive starch;

[0079]Nanofillers include a mass ratio of 0.7: 1.2: 0.45: 0.42: 2.6, a bump, titanium powder, leaf wax powder, calcium carbonate and ceramic fine powder; the particle size of the uneven ripple and leaf wax powder is 100 ~ 200 ...

Embodiment 3

[0087]Artwater powder containing nanochemistry, including raw materials of the following weight parts:

[0088]30 parts of epoxy resin modified benzide emulsion, 2 serial oxygen resins, 1 part of ascorbic acid, 2 parts sodium citrate, 2.5 parts of tetrahydrodethalic anhydride, 18 plants, 3 parts of polyethylene wax, 6.5 sodium dodecyl benzene sulfonate, 1.7 parts of tannicate, 4.5 parts gas phase silica, 10 nano filmers, 26 parts of organic pigment powder, 3.7 fragrant agents, 45 oleate, 14 parts Glycerin, 1.4 parts of sodium sulfite and 55 parts;

[0089]The particle size of gas phase silica is 20 to 40 nm;

[0090]Plant gum includes a mass ratio of 5.6: 1.7: 2.4: 3.1: 1.5: 1 pectin, maltitol, karam, starch nano, maltodextrin and pre-adhesive starch;

[0091]Nanofillers include a mass ratio of 0.8: 1.4: 0.35: 0.48: 2, a torium, titanium powder, leaf wax powder, calcium carbonate and ceramic fine powder; the particle size of the concavestone earth and the leaf wax powder is 100 ~ 200 mesh; tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com