Preparation method of hollow mesoporous Ti4O7@C nanospheres with large specific surface areas

A large specific surface area, hollow mesoporous technology, applied in nanotechnology for materials and surface science, carbon preparation/purification, nanotechnology, etc., can solve the problems of small specific surface area and grain coarsening of composite materials, To achieve the effect of shortening the reaction time, short reaction time and speeding up the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of TiO 2 @C nanosphere

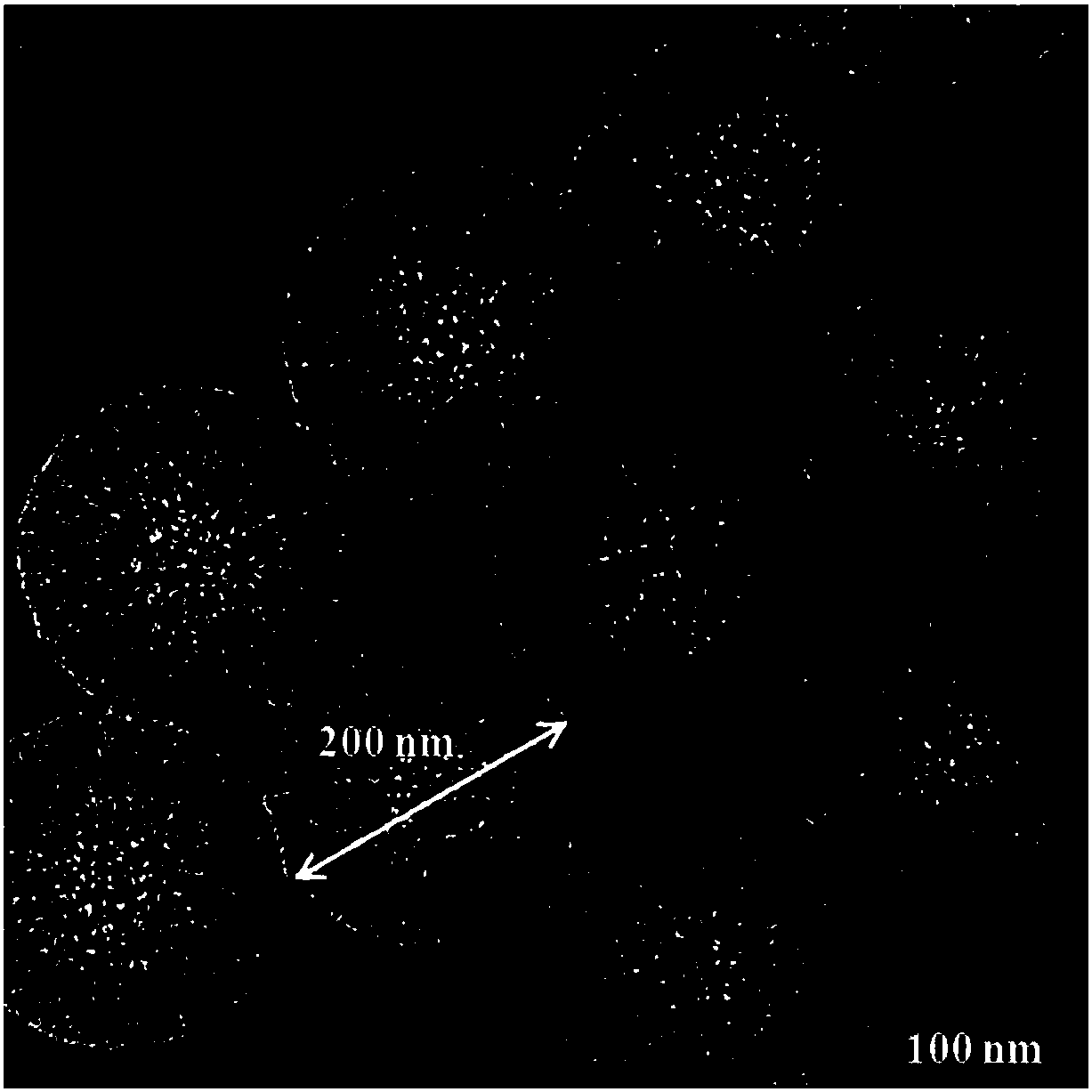

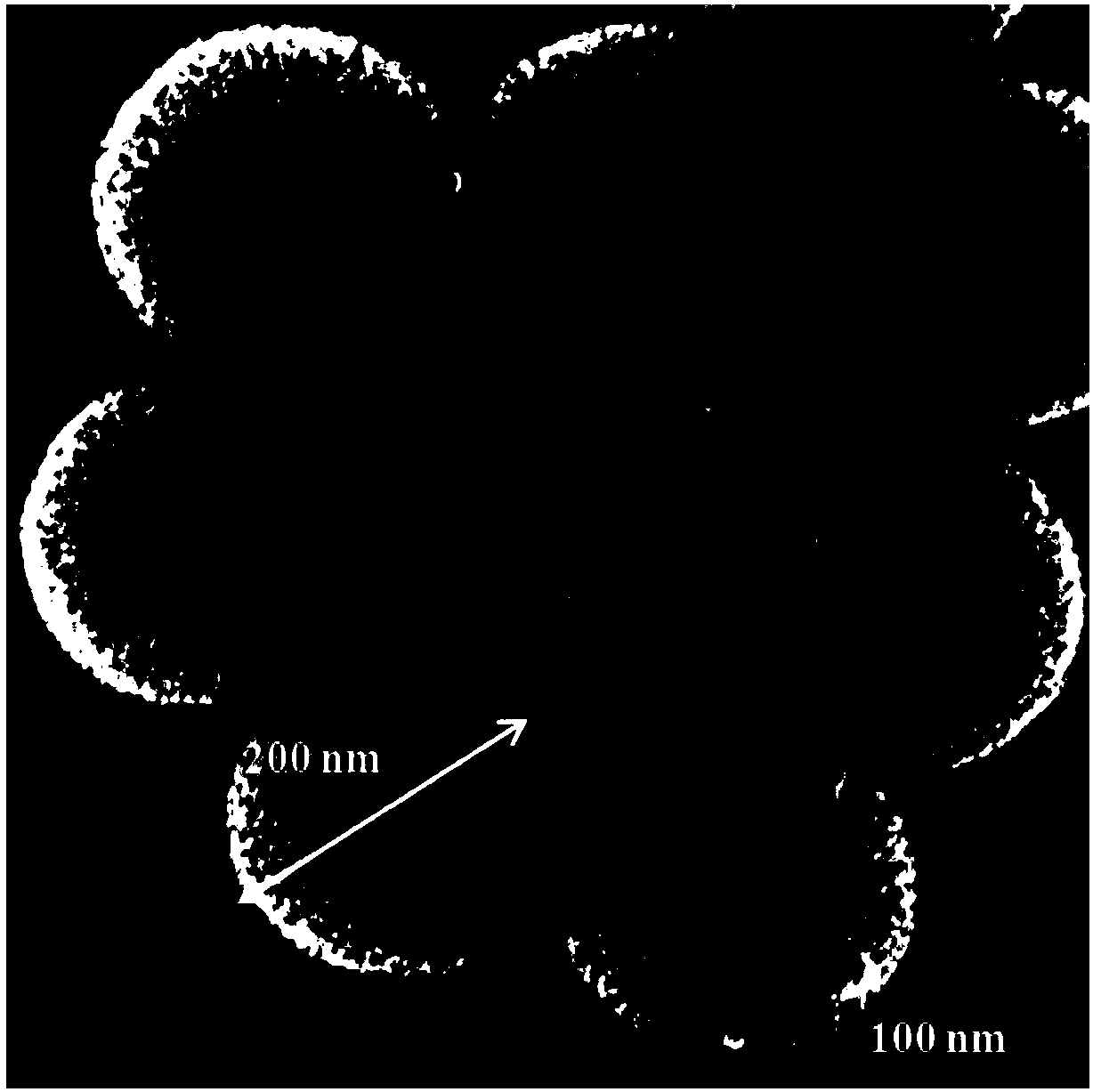

[0034] Add 30mg of hollow mesoporous carbon spheres with an average particle size of 200nm and a wall thickness of 40nm into 35mL of absolute ethanol, ultrasonically disperse at room temperature for 30 minutes, then add 0.32g of cetylamine and 0.8g of ammonia water with a mass concentration of 25% , stirred at room temperature for 15 minutes, then added 0.2 g titanium isopropoxide dropwise, continued to stir for 1 hour, and washed twice with deionized water to obtain TiO 2 @C nanospheres.

[0035] 2. Preparation of PDA@TiO 2 @C nanosphere

[0036] 0.1g TiO 2 @C nanospheres were added to 55 mL of Tris alkali-hydrochloric acid buffer solution with a pH of 10, dispersed by ultrasonic at room temperature for 5 minutes, added 0.1 g of dopamine hydrochloride (PDA), stirred at room temperature for 24 hours, centrifuged and washed with deionized water for 3 times, and then washed with Centrifuge and wash twice with water and ethanol,...

Embodiment 2

[0043] In step 1 of this example, 20 mg of hollow mesoporous carbon spheres with an average particle size of 200 nm and a wall thickness of 40 nm were added to 35 mL of absolute ethanol, and ultrasonically dispersed at room temperature for 30 minutes, and then 0.32 g of cetylamine, 0.8 g mass concentration is 25% ammonia water, stir at room temperature for 15 minutes, then dropwise add 0.2g of isopropoxytitanium, continue to stir for 1 hour, and wash twice with deionized water to obtain TiO 2 @C nanospheres. Other steps are identical with embodiment 1, obtain hollow mesoporous Ti 4 o 7 @C nanospheres (see Figure 13 ).

Embodiment 3

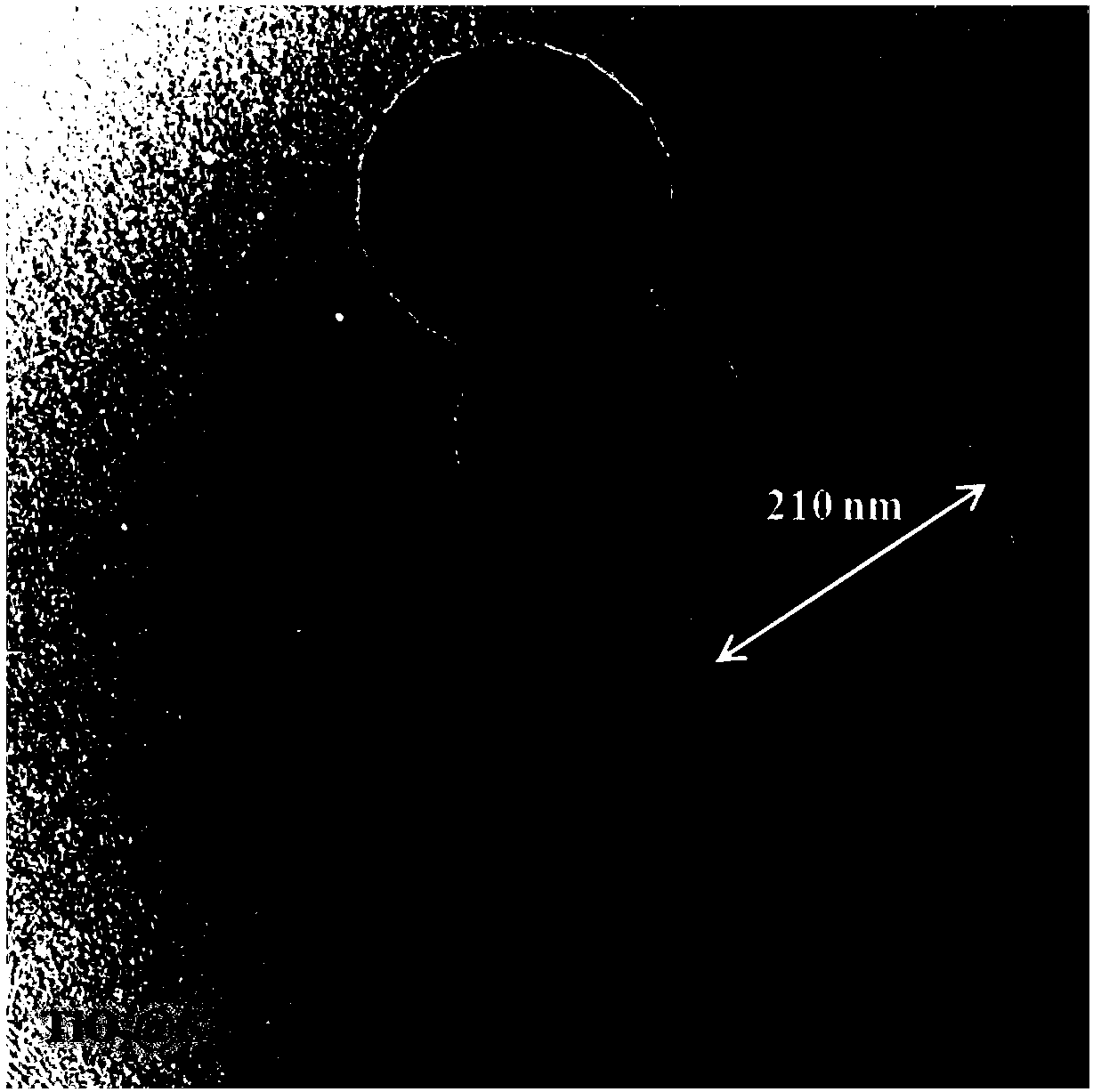

[0045] In step 2 of the present embodiment, 0.1g TiO 2 @C nanospheres were added to 55 mL of Tris alkali-hydrochloric acid buffer solution with a pH of 10, dispersed by ultrasonic at room temperature for 5 minutes, added 0.2 g of dopamine hydrochloride (PDA), stirred at room temperature for 24 hours, centrifuged and washed with deionized water for 3 times, and then washed with Centrifuge and wash twice with water and ethanol, and dry at 60°C for 12 hours to obtain PDA@TiO 2 @C nanospheres. Other steps are identical with embodiment 1, obtain hollow mesoporous Ti 4 o 7 @C nanospheres (see Figure 14 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com