Novel bathroom glass edge grinding machine

An edge grinding machine and glass technology, which is applied to machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc. and other problems, to achieve the effect of preventing dust splashing, improving edge grinding efficiency and realizing environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

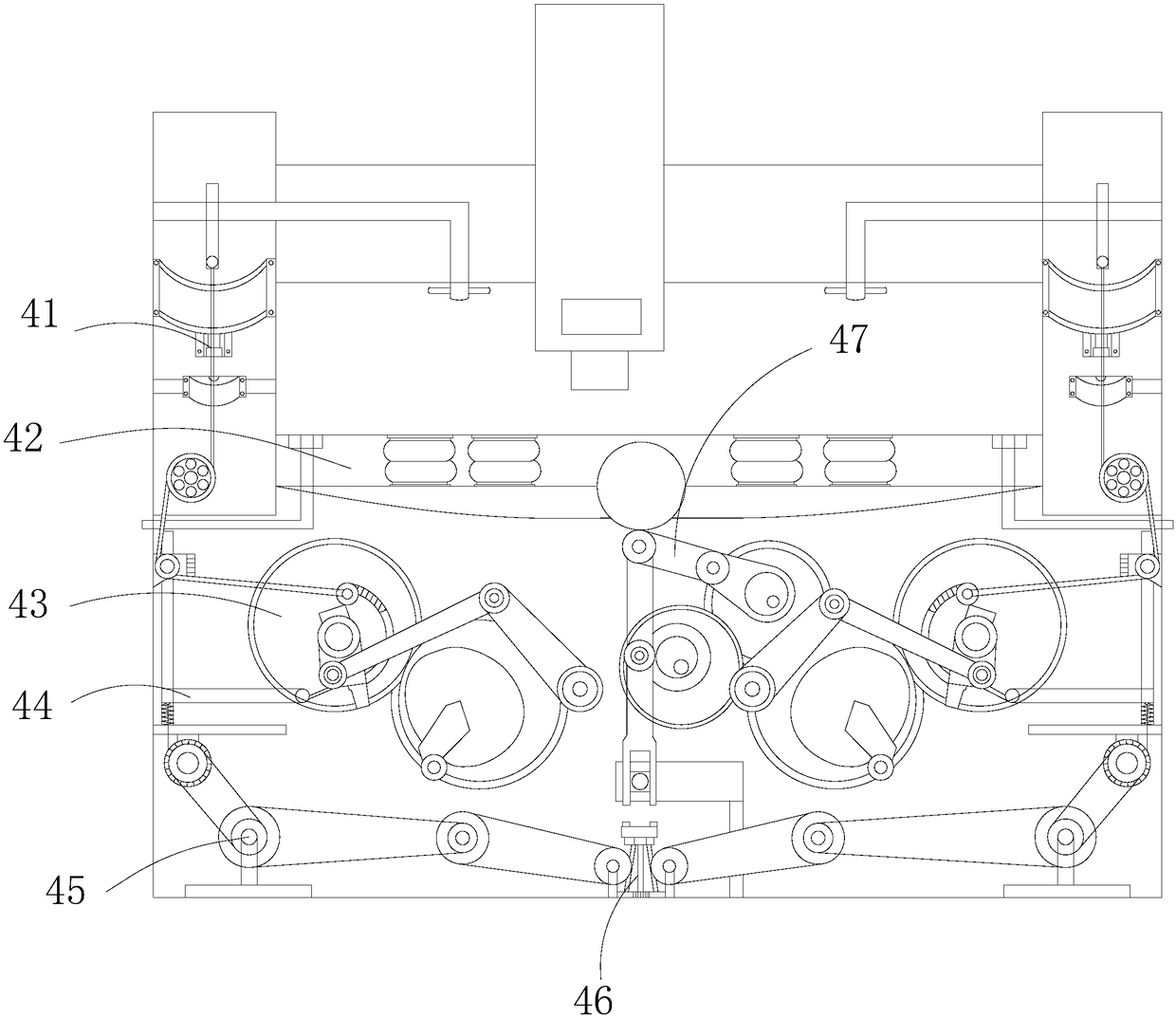

[0025] see Figure 1-Figure 5 , the present invention provides a novel bathroom glass edging machine, the structure of which includes a moving track 1, a grinding head 2, an operating host 3, and an edging workbench 4. The edging workbench 4 is a U-shaped structure and the central depression is horizontal The moving track 1 is fixed, the rear end surface of the grinding head 2 is engaged with the moving track 1 and adopts a clearance fit, the operating host 3 is installed inside the right end of the edging workbench 4 and the signal end is connected to the signal of the grinding head 3 end, the edging workbench 4 is composed of a movable barrier mechanism 41, a platen mechanism 42, a cam traction mechanism 43, a limit mechanism 44, a transmission mechanism 45, a driving device 46, and a cam linkage mechanism 47. The movable barrier mechanism 41 There are two and are all installed inside the two ends of the edging workbench 4. The platen mechanism 42 is located inside the reces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com