A low-temperature antifreeze water-cooled motor pump unit and a high-pressure cleaner

A motor pump, water-cooled technology, applied in the direction of pump components, electrical components, machines/engines, etc., can solve the problems of motor pump cracking, machine freezing cracking, etc., and achieve the effect of preventing corrosion and solving low temperature antifreeze problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

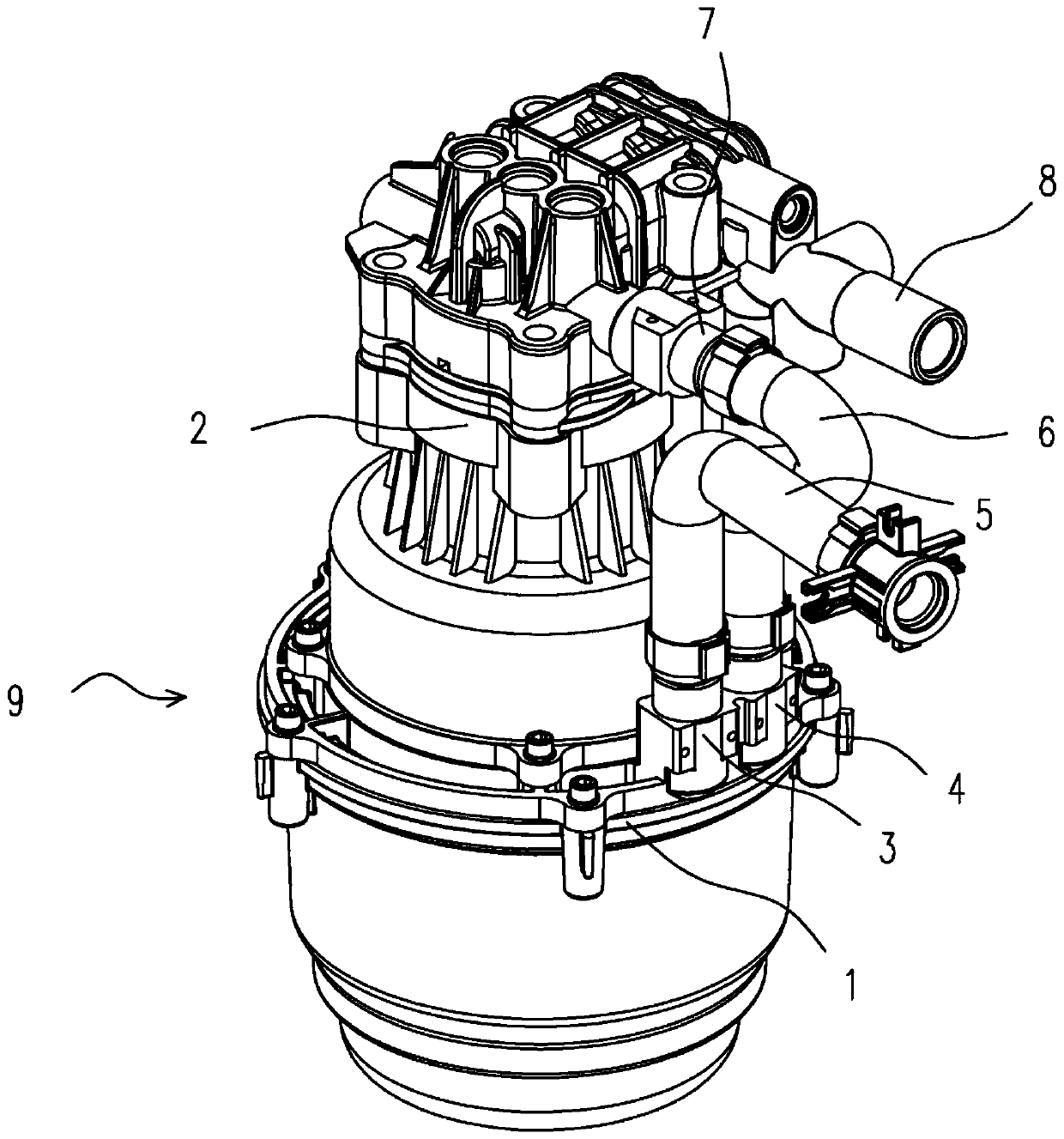

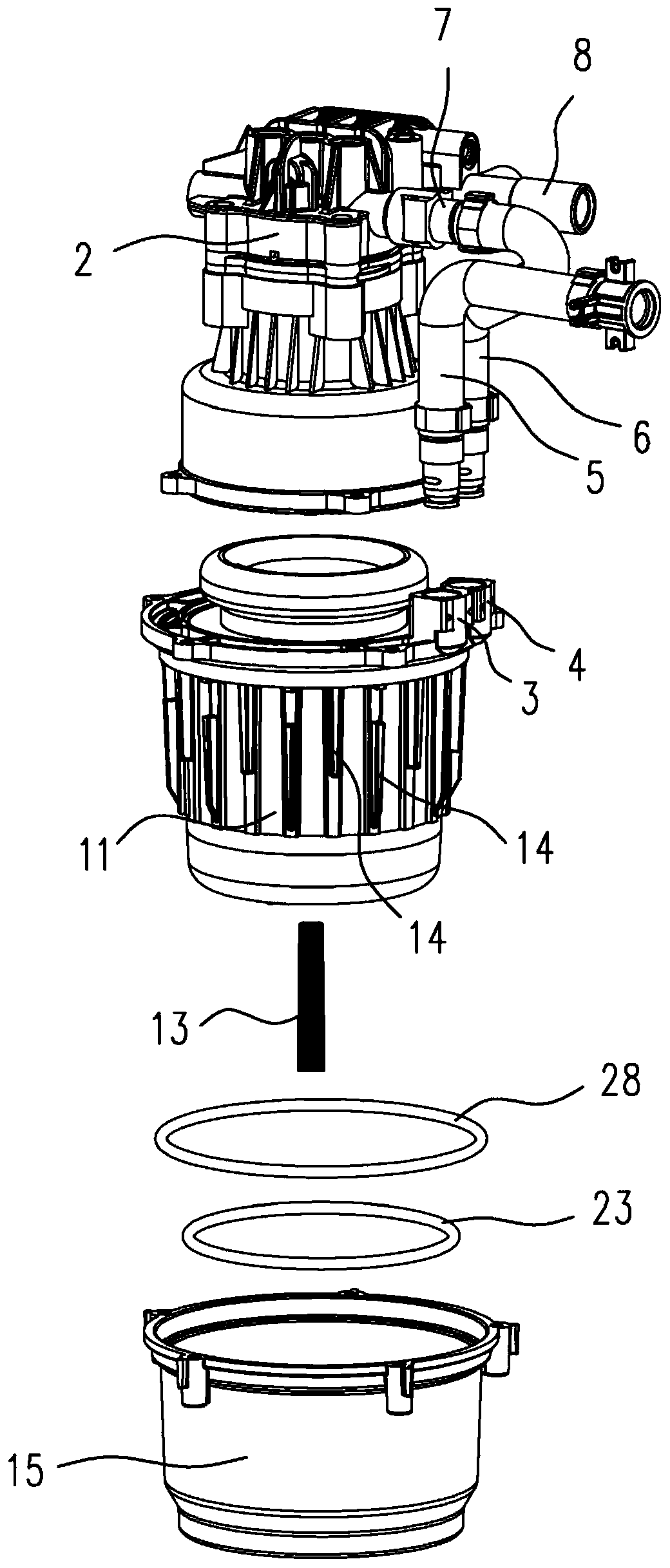

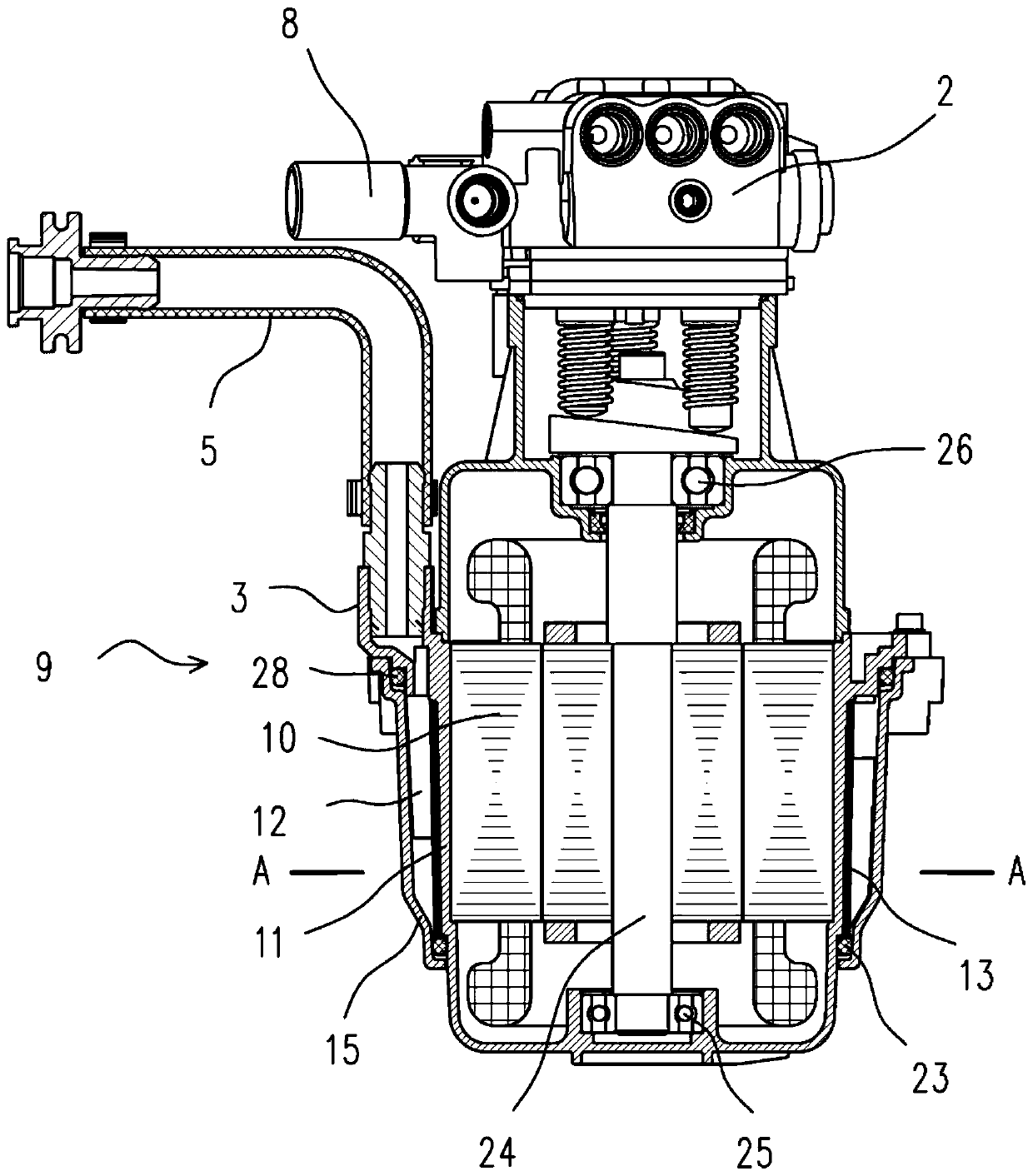

[0039] Such as Figure 1 to 4 As shown, a high-pressure cleaner includes a spray gun unit and a motor pump unit 9. Water from an external water source such as a municipal water pipe enters the motor pump unit 9 through the water inlet pipe 5, and flows into the spray gun unit through the pump outlet 7 after being pressurized. The nozzle of the spray gun unit forms a high-pressure water jet to spray out. The improvement of the present invention lies in the motor pump unit 9, so the spray gun unit will not be described in detail.

[0040] The motor pump unit 9 includes: a pump 2 and a water-cooled motor 1. The pump 2 has a pump inlet 7 and a pump outlet 8; the water-cooled motor 1 has an iron core 10 and a shell 11 close to the iron core 10. The body 11 is provided with a water-cooling cavity I12. The water-cooling cavity I12 has a water inlet 3 and a water outlet 4. The water inlet 3 is connected to an external water source through a water inlet pipe 5; the water outlet 4 is conne...

Embodiment 2

[0046] Such as Figure 5 As shown, the difference from the first embodiment is that, in this embodiment, at least one slot 16 connected to the housing 11 is provided in the water-cooling cavity I12, and the elastic body I13 is located in the slot 16 and close to the water-cooling rib 14. Arranging the elastic body I13 on the side of the water-cooled rib 14 can prevent the surface of the housing 11 from being corroded.

Embodiment 3

[0048] Such as Figure 6 to 11 As shown, the difference from the first embodiment is that in this embodiment, the water-cooled motor 1 is a brushless motor 17. The brushless motor 17 also includes a controller 18 and a controller water-cooled body 19 connected to the controller 18. The controller water-cooled body 19 is provided with a water-cooled cavity II20 communicating with the water-cooled cavity I12, and the periphery of the water-cooled cavity II20 is communicated with the top opening of the water-cooled cavity I12. The water-cooling cavity II20 has a controller water-cooling body water inlet 21, and a number of elastic bodies II22 are arranged in the water-cooling cavity II20. The function and principle of the elastic body II22 are the same as the elastic body I13, so it will not be repeated. The water-cooling cavity I12 extends in the axial direction to the top end surface 36 of the housing 11 and is arranged as an open opening. Based on this structure, the housing 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com